SAG and ball mills are the most critical equipment in MM process Wireless Temperature Monitoring avoid damages and unplan shutdowns. When the mill is overloaded with more minerals than it can grind, energy consumption increases, and temperature in the poles as well, it would damage the motor and stop the mill. ...

SAG BALL MILL PRINER

Single stage AG/SAG milling AG/SAG mills as a primary grinding stage in a circuit with or without additional stages of comminution Inclusion of pebblecrushing circuits in the AG/SAG circuit Circuits above, but with feed preparation including two stages of crushing—typically referenced as precrushing

The biggest characteristic of the sag mill is that the crushing ratio is large. The particle size of the materials to be ground is 300 ~ 400mm, sometimes even larger, and the minimum particle size of the materials to be discharged can reach mm. The calculation shows that the crushing ratio can reach 3000 ~ 4000, while the ball mill's ...

6 Table 3 Parameter Ranges Covered by CITIC SMCC Data Bases Parameter Units max min Ore characteristics DWi kWh/m3 Bond ball Wi kWh/tonne 26 6 JK A*b sg 182 20 AG/SAG mill ...

Combine ABB's variablespeed drive system with advanced process control ABB Ability™ Expert Optimizer for grinding to provide maximum mill control. It can be applied to new or existing AG, SAG and ball mills, powered by either ringgeared mill drives (RMD) or gearless mill drives (GMD). This solution was designed to control, stabilize and ...

If a ball mill uses little or no water during grinding, it is a 'dry' mill. If a ball mill uses water during grinding, it is a 'wet' mill. A typical ball mill will have a drum length that is 1 or times the drum diameter. Ball mills with a drum length to diameter ratio greater than are referred to as tube mills.

SAG mills have a power higher than 10 MW. Even ball mills have a power larger than 10 MW. For this reason, they have an important impact in energy consumption and in the operation of the power distribution system. Figure 1. Picture of a typical GMD system for a SAG mill Figure 2 presents the power circuit of a cycloconverter fed synchronous motor.

The pairing mill combination of a SAG/Ball mill is common in copper/gold mines for that reason. This combination can aim for a fine product sizes are around typically 100200 micron whereas a Vertimill or ISAMill are finer at 2040 micron or smaller.

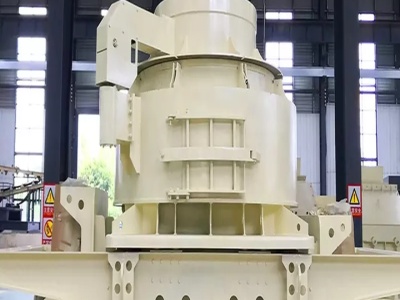

AG Mill and SAG Mill. Feeding size: ≤25mm. Capacity: .65615t/h. Output size: Applications: It is commonly used in the mineral processing industry and ferrous and nonferrous metal ore and nonmetal ore processing plants. It can also be used in cement plant, refractory plant, fertilizer plant and smelting plant.

In fact, in four of the surveys, the SAG mill was found to be more efficient at producing circuit product than the ball mill. Similar results have been seen consistently across all the surveys where this approach has been used, including circuits with AG mills, pebble mills, HPGR, stirred mills and ball mills with fine screens. Figure 2 ...

Ball Mill. The proven classical option for cement grinding. Whether employed as a twocompartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust and reliable alternative for cement and granulated blast furnace slag grinding. Used in combination with the sepol ...

Figure 5. Highlow wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc. liner design and material of construction are integral and cannot be chosen in isolation.

An extension of the previous circuit is the SAG/Ball Mill circuit. This option comprises an open circuit SAG mill followed by a closedcircuit ball mill. Due to the high throughputs associated with this circuit, the ball mill is most often closed with a hydrocyclone classifier. The course material is returned to the ball mill feed and the fine ...

A total of 120 t of Cristalino ore was prepared and sent to CIMM, where it was crushed and screened prior to grinding tests. The processing equipment included a m (8′) diameter by m (2′) length AG/SAG mill equipped with a 20 kW motor, a cone crusher, a m (3′) diameter by m (4′) length ball mill equipped with a 15 kW ...

Then, in the late 1980s when the price of copper rose quickly from a low of /lb to a high of /lb, this substantial increase in price further fuelled the industry demand for larger diameter SAG mills, with mill power quickly doubling from 15,000hp to 30,000hp (11,00022,000kW). As SAG mills grew in size and number, so did the size and ...

HPGR test results published by Grier (1992) on gold ores from the Mt. Todd project showed significant energy savings for a HPGR/Ball Mill circuit as compared to a SAG/Ball Mill plant. By adding a Polycom highpressure grinding roll, the throughput of existing plants can be increased by as much as 150% while simultaneously reducing the power ...

The respective portions report to SAG 1, SAG 2, Ball Mill 1, and the gravity screen. The pr oduct from SAG 2 is pumped to t he hydrocyclone which is in cl osed circuit

An open source ball mill has been designed that can be fabricated with a 3D printer for a few hundred dollars. [3] It is able to be operated both on grid for lab work and off grid with solar photovoltaics and a battery for field work. [3] Blending of explosives is an example of an application for rubber balls. [4]

> Mill throughput and efficiency gains are iterative over time > Mill trajectory modelling based on bar heights, angles, spacing and speed is very predictive > Field trials are the acid test operator, designer and vendor > Optimisation strategy: Maximise impact grinding AG/SAG mills Avoid impact on the shell rather the toe of the charge

See more reviews for this business. Top 10 Best Brother Printer Repair in San Jose, CA October 2023 Yelp Bay Area Printer and Data Services, The Printer Doctor, Printer Assist, ClickAway Computer Repair + IT Services, Stone Systems, uBreakiFix by Asurion, ClickAway Computer Repair, Phone Hut Cell Phone Repair.

SAG mill, ball mill, float, MT Concentrate Leach HPGR, ball mill, float, MT Concentrate Leach 47,468 41,169 47,055 45,453 39,186 % % % % 1 Includes energy for mining through final ...

Improving Cheap Ball Screws. Most 3D printers use leadscrews for at least one axis. These are simple devices that are essentially a steel screw thread and a brass nut that travels on it. However ...

The proportion of SAG and ball mills in producing the final product (particles finer than 74 µm) was % and % respectively. That is, the SAG mill produces about % more than the ball ...