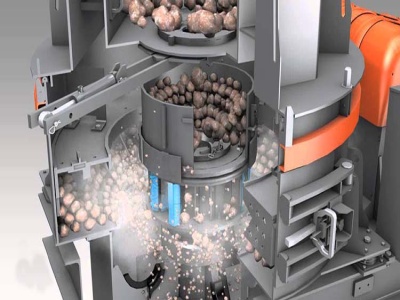

INTRODUCTION The energy consumption for grinding, according to Bond (1961), is deter mined by the formula: / 10 10 (I) The work index is determined by grinding experiments carried out in a labo ratory Bond ball mill. Based on the results of grinding experiments, numerical values of the work index Wi are calculated according to the formula ...

Ball Mill 200 Mesh Powder

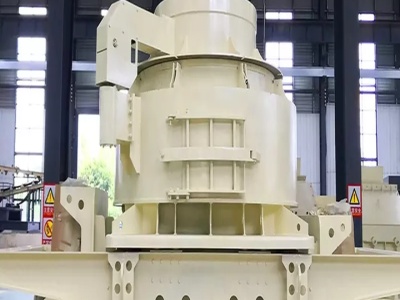

DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h1000 g/h). For small to large scale operations, DOVE Ball Mills are supplied in 17 models, capacity range of ( TPH 80 TPH).

Please subscribe! Thank you for watching!I wanted to see if I had any 500 mesh (less than 25 micron) size aluminum powder in the ball mill yet. So I processe...

The sphericity of solid particles is for the material between 4 mesh and 200 mesh in particle size. Mesh No. Screen opening, D pi (mm) Mass fraction retained ... One tonne per hour of dolomite is produced by a ball mill operating in closed circuit with a 100mesh screen.

Planetary Ball Mills. Sample volumes up to 4 x 220 ml. Final fineness*: µm. Extremely high centrifugal forces result in high energy input. Dry and wet grinding by impact and friction. To the product range. Ultrafine grinding with up to 76 g.

The "M" Series fine grinders are designed to grind dry, freeflowing material down to 400 mesh with extremely tight particle size distribution. This highly efficient machine ensures easy access to all internal areas and is perfect for heatsensitive materials, such as resins, sugars, and powder coatings. Notable features include a final ...

MICRON POWDER SYSTEMS g Mill AWA Air Classifyin. ... Phenolic Resin 1/2" 97% < 200 Mesh Zinc Sterate 1/8" Flakes 97% < 38 µm Potassium Phosphate 240 µm 90% < 48 µm Soda Ash 100 µm50% < 15 Powder Coatings 1/4" Chips 50% < 25 µm Thermo Plastic Polymer 25 mm 90% < 1070 µm

In this study, 430 µm, 200 µm, 165 µm, and 60 µm mesh sizes were used. After 12 h, the samples were analyzed using Malvern Instruments for particle size distribution. ... The ball mill process parameters discussed in this study are ball to powder weight ratio, ball mill working capacity and ball mill speed. As Taguchi array, ...

The ballmilled powder exhibited the highest dissolution rates and largest dislocation densities. ... but a small amount of residual coarse material was removed with a 200 mesh screen. Comminuted materials from the puck mill, roll mill, ball mill and pulverizer were dry screened by mechanical shaking for 15 min. Screens of 500, 325 and 200 mesh ...

Listed below are all the Schuetzen Powder Distributors find one near you! Find a Schuetzen Dealer. Please abide by all manufacturer and government guidelines and regulations when handling, storing, and using blackpowder. To make this easier we have links to both Hodgdon/GOEX and Scuetzen's warnings in the buttons below.

cost (for instance, from 50 to 200 percent higher than most hammermills), its ability to precisely reduce particles while using less energy and producing little waste can provide a relatively fast return on investment. When selecting a roller mill, work closely with the mill manufacturer to choose the optimal unit for your application.

California Powder Works was the first American explosive powder manufacturing company west of the Rocky Mountains. When the outbreak of the Civil War cut off supplies of gunpowder to California 's mining and roadbuilding industries, a local manufacturer was needed. Originally located near Santa Cruz, California, the company was incorporated in ...

Benchmark Scientific .is an extremely versatile bead mill homogenizer that has applications in a variety of areas, including biological research, environmental testing, and industrial settings. Adapters are available for microplates, microtubes, and 50ml tubes. Grinding jars and balls in a variety of materials are.

sbm hammer mill for 200 mesh powderPrice Hammer Mill Stone 800 Mesh,200 Mesh Hammer . ball mills hammer mill indonesia mesh 200 Grinding hammer mill stone mesh 800 st

Dried 3/8″ Minus Crushed Oyster Shells. Wet 3/8″ Minus Crushed Oyster Shells. 1″ Minus Crushed Oyster Shell. Medium Clam Shells. A number of different applications call for crushed oyster shell flour. Topcoats for bocce ball courts, plaster and stucco finishing, and water treatment. Oyster shell flour is more commonly called ground calcium.

Nutraceuticals Group

Dry batch milling tests were performed in a laboratory scale ball mill measuring by cm. The mill specifications are given in Table 1. A constant ball load of 20% was maintained in all the tests with a ratio of for binary and for trinary ball mix.

The study showed that the combination of the BPR and powder type affects the particle size result. The optimum of BPR at 12 with the number of balls is 60 pieces, and the filling rate is %. The result shows that the horizontal ball mill able to grind the calcium carbonate to a size of smaller than 100 mesh (149 µm).

100 / 150 / 305 / 400 / 450 mm Mesh Sieves. The wellproven RETSCH sieves consist of a solid stainless steel sieve frame of high stability for reliable sieving results. Paying close attention to meshspecific requirements, the sieve fabric is precisely joined into the frame and tautened. RETSCH test sieve provides a clear and accurate labeling ...

The balltopowder weight ratio is usually selected to be in the range between 10:1 and 50:1. ... ballmills/), namely Planetary Ball Mill PM 100 (Fig. A), Planetary Ball Mill PM 100 CM, Planetary Ball Mill PM 200, and Planetary Ball Mill PM 400 (Fig. B). Likewise Fritsch, Retsch offers highquality ball milling vials with different ...

Lab mills for grinding, pulverizing, chopping samples for routine analysis. ... Mesh Screen Discs, Sheets and Net Filters; Pressure Filtration; Radiochemistry; Solid Phase Extraction; ... ColeParmer BM200 Mini Mixer/Mill® Compact Ball Mill; 115/230 VAC. EW. 4, USD / Each. Add To Cart +ADD TO LIST . COMPARE.

In this case, the vacuumdried powder was ball milled using a planetary instrument at 400 rpm for up to 8 hours with 10 minutes pauses every 10 minutes. The resulting material was then passed through the HPH and subsequently washed with distilled water. ... The esterification reaction was then performed in a planetary ball mill at 200 rpm using ...

An iron powder ball mill is used to grind iron powder directly, as some industries don't require high iron content and prefer coarser iron powder. The iron powder ball mill grinds the iron powder to a certain size, typically 100200 mesh, which can then be used in magnetic separation processes to extract iron powder. The

The Platteville Powder mills were wrecked by an explosion this afternoon, killing three men and badly injuring another. The dead are: Thomas Bass, William Rottiger and Fred Genthe. H. S. Beck, a machinist of Bethlehem, was badly hurt. The cylinder mill exploded first, and this was followed by the two presses, the shock being felt for miles around.

Ball mills can be used to further break down or refine a single material, or you can place multiple materials into a ball mill jar to mix as you pulverize this is a very common industrial solution for mixing glazes that require the smallest of mesh sizes. Ball mills basically function like a mortar and pestle, but on a much larger scale.

Preparation of graphene by ball milling • The best preparation scheme is: flake graphite (50 mesh) 20 g, ball milling time 5 h, ball milling speed 410 r/min, aluminum particle diameter ratio 200 mesh:500 mesh = 1:, aluminum total mass g, steel sand particle size mm: mm = :1, steel sand total mass g. •

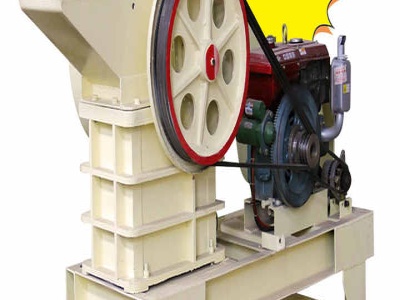

Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually times the shell diameter (Figure ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 2040% water by weight.

Polytetrafluroethylene ultrafine powder. PTFE ultrafine powder can be prepared by irradiation at room temperature, followed by ultrafine grinding. Fresh PTFE material, scrap or recycled PTFE waste, etc., can be used to fabricate ultrafine powder. The use of recycled PTFE or waste to produce ultrafine powder can reduce the cost and achieve ...

BallRod Mills, based on 4″ liners and capacity varying as power of mill diameter, on the 5′ size give 20 per cent increased capacity; on the 4′ size, 25 per cent; and on the 3′ size, 28 per cent.

A novel process using supercritical fluid has shown to be effective for REEs recovery from secondary sources. The process utilizes supercritical CO 2 as the solvent, which is safe, inert, and abundant, in addition to tributylphosphatenitric acid (TBPHNO 3) chelating agent to extract REEs from solid et al. [] achieved over 85% of rareearth elements (including La, Ce, Pr, and ...

Nanosized Fe 3 O 4 particles were prepared by wet milling metallic iron powder (−200 mesh, 99%) in a planetary ball mill equipped with stainless steel vials using iron balls under distilled water with a balltopowder mass ratio of 50:1 and at a rotation speed of 300 rpm. The use of the iron balls in this method played a key role in Fe 3 O 4 ...

A ball mill is a pulverizer that consists of a horizontal rotating cylinder, up to three diameters in length, containing a charge of tumbling or cascading steel balls, pebbles, or rods. ... with a static classifier is capable of producing a coal fineness up to % or higher <50 mesh and 80% or higher <200 mesh, while one equipped with a ...

40 mesh. Dalam pembuatan ball mill, dengan diameter tabung 20 cm, ... namely the reduction of the dimensions of the rock into a powder size of 40 mesh. In making ball mill, with a tube diameter of 20 cm, the operating speed of the tool and loading charge are ... = 200 untuk . ball mills . dan 300 untuk . rod mills. Wi = indeks kerja . Vcr =