Clinker definition, any mistake or error. See more.

Clinker Ball Mill Mill Clinker Mill Mill

vertical roller grinding mill LM190K. vertical for limestone stone. Final grain size: 45 µm 170 µm. Output: 23 t/h 72 t/h. Motor power: 500, 450 kW. LM series vertical mill is one advanced mill adopted top technology of domestic and abroad, and based on many years' mill experience. LM vertical mill can be widely used ...

Samples of the input, output and return material of cement clinker grinding by a CKP mill are collected, based on the field sampling in the industrial mill. The crushing kinetic process of the cement clinker in a CKP mill is analyzed, by using the particle size distribution and mass balances. The following results have been obtained. 1.

Ball Mill Mineral Agitation Barrel SF Series Flotation Cell 6S Shaking Table Spiral Chute Magnetic Separator. ... Production process of 5000tpd clinker cement. . Learn more. 5000tpd Active Lime Production Process. . Learn more. Equipment needed for stone crushing production line. .

Coming now to the ball mill, we are reaching the ex perimental stage of milling as applied to cement clinker. Ball mills . and . pebble mills have been used in a number of plants. ~hie . mill in its simplest conception consists of a cylinder revolTing around a horizontal axis with die plates arourid the circumference. ~he

Cement Milling. Cement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of grinding media (steel balls). Grinding clinker requires a lot of energy. How easy a particular clinker is to grind ("grindability") is not always easy to predict, but large clusters of belite due to coarse ...

In ball mills, for example, less power is required to produce finished cement from Hydraulic Roller Presspressed material than from unpressed material. ... TRIBOMAX® has a 25,000hour minimum guaranteed lifetime for Clinker grinding applications and can be designed to guarantee up to 40,000 hours of lifetime in select cases. We also provide ...

Nowadays, ball mills are used widely in cement plants to grind clinker and gypsum to produce cement. In this work, the energy and exergy analyses of a cement ball mill (CBM) were performed and ...

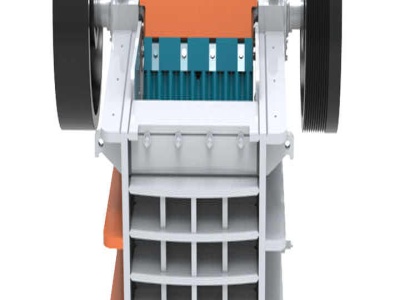

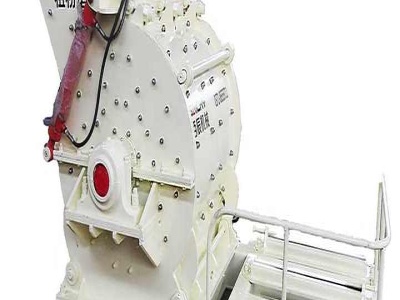

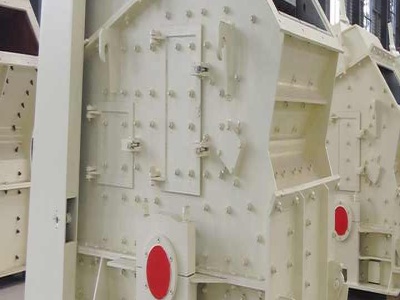

Combinations of milling techniques including ball mills, roller mills, or roller presses are often applied to ground clinker with additives in cement mill. The finished cement is being transferred via bucket elevators and conveyors to silo for storage [9]. Figure 2: Cement Manufacturing Process

Nowadays, ball mills are widely used in cement plants to grind clinker and gypsum to produce cement. The research focuses on the mill speed as well as air classifier speed effect on the two ...

Nowadays, ball mills are widely used in cement plants to grind clinker and gypsum to produce cement. The research focuses on the mill speed as well as air classifier speed effect on the two ...

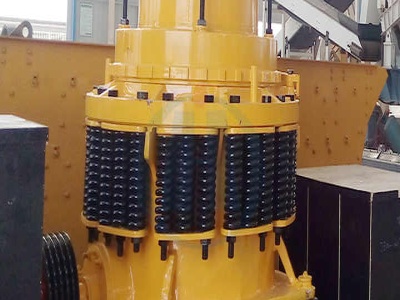

For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality. Further, our vertical roller mill solution for cement grinding has an ability to dry, grind and separate within a single ...

Contribute to hedaokuan/fr development by creating an account on GitHub.

clinker grinding ball mill Simulation of clinker grinding circuits of cement plant. CEMENGAL: ENGINEERING,EQUIPMENT AND ASSEMBLY FOR THE. clinker cement clinker grinding is ball

Contribute to legaojm/m development by creating an account on GitHub.

The aim of this study was to examine the breakage kinetics of premilled cement clinker in a labscale ball mill loaded with steel or alumina balls of 20, 30, and 40 mm sizes as well as their mixtures. In each milling experiment, samples of the milled clinker were collected at various time intervals, and the temporal evolution of the PSD was ...

15tph Clinker Ball Mill for Cement Plant, Find Details and Price about Clinker Ball Mill Clinker Mill from 15tph Clinker Ball Mill for Cement Plant Zhengzhou Hengxing Heavy Equipment Co., Ltd.

At most manufacturing plants the ball mill is used to grind the clinker and, since the production rate is directly related to the amount of electrical energy supplied, the power of the electric motor used to turn the mill is a firstorder measure of the output achieved. Mills vary in their power input from as little as 200 kW up to 10000 kW.

The following are several important factors affecting the cement clinker quality. In the process of clinker production, strict control of these factors can ensure the production of highquality, highyield clinker. 1. Lime Saturation Factor. The lime saturation factor (LSF) is a ratio of CaO to other oxides, it is used to control the proportion ...

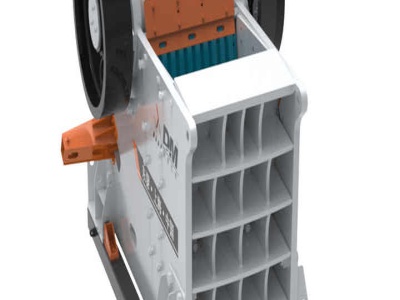

Cement ball mill is a kind of cement grinding equipment commonly used in cement plants. It is mainly used for grinding materials in cement clinker section. Cement ball mill is widely used in cement production, silicate products, new building materials, refractories, fertilizers, black and nonferrous metal mineral processing, glass, ceramics, and other industries.

of the mill. After the grinding period has been completed, the mill is discharged by tilting it downward at an angle of 45" for 30 revolutions. The unit volume present in the mill in all tests is 1250 of dry solids packed by shaking, and the number of grams occupy ing 1250 is the unit test weight. Unless

For instance, in large diameter ball mills, the impact force of the grinding media is so great, that a high material surface unbalance prevails in the mill when grinding all types of clinker, thus requiring a grinding aid at all times. ... For clinker: Ball weights sizes and densities Ball weight = [diameter (mm)]3 / 250. LAFARGE. Ball Size ...

The ball mill liners are located on the inner surface of the ball mill barrel, which protects the barrel from the direct impact and friction of the grinding media and the material. The ball mill liners' material and shape are different base on requirements. When the grinding media contacts different shapes of ball mill liners, the movement state will also change, thus enhancing the crushing ...

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles ...

Page Mill Rd, Palo Alto, CA. Properties. Are you looking for a specific property? SEARCH. 1. Start entering a street number. 2. Select the street address from the dropdown. 3. Get property owners, residents, neighborhood info in seconds! Address. 200 Page Mill Rd. Palo Alto, CA 94306. Details. 18,704 sqft. Office Building. Built in 1986.

Contribute to jidafang2022/en development by creating an account on GitHub.

A mediumsized dry process roller mill. A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished ...

approximately 40% is consumed in the clinker grinding (Jankovic et al. 2004). Despite its energetic eectiveness is very low, ball mills are traditionally the most used devices to the grinding of this material (Camalan and Hoşten 2015; Sridhar, Sankar and Prassad 2016; Mishra et al. 2015). This device consists of a cylindrical drum that horizon

To investigate the effects of grinding media shapes on the grinding kinetics of ball mill cement clinker, the grinding effects with ϕ20 mm balls and ϕ20 × 20 mm cylinders on six different size ...

A 10 MW cement mill, output 270 tonnes per hour. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

The cement ball mill in this clinker grinding unit adopts the open circuit grinding method. The open circuit grinding system has the advantages of a simple process, less equipment required, a small plant area, easy operation, convenient management, and a high operation rate. In this clinker grinding unit, the roller press system's air release ...