This set of Mechanical Operations Multiple Choice Questions Answers (MCQs) focuses on "Crushing Efficiency". 1. Which of the following works on principle of compression and impact? a) Jaw crusher b) Gyratory crusher c) Fine crusher d) Tramp crusher 2. The feed size of gyratory crusher varies from ____ a) 150190 mm b) 200800 mm ...

تكوين Crushershammer Mill Crushers

The Standard and NonClog Industrial Hammermills are designed to reduce the material to a nominal 3" to 5" (75mm to 25mm) output. These are primary stage crushers, commonly followed with Centerfeed Mills or other types of secondary stage crushers. The HammerMaster is also a secondary stage crusher in that the maximum feed size is 6" (150mm).

This is a demonstration for a client running a 12"x9" hammer mill dry with a 1 mm bar gap spacing. At the end of the video we show the results of the test u...

Eagle Crusher Hammermills are designed for maximum strength at a minimum weight. They are ideal for use when budget and space are limited, particularly as they require a lower initial investment than horizontal shaft impactors (HSI), or when portable mounting is limited. Their replaceable, heavyduty grate bars assure precise product sizing ...

Ball Mills. Ball mills have been the primary piece of machinery in traditional hard rock grinding circuits for 100+ years. They are proven workhorses, with discharge mesh sizes from ~40M to <200M. Use of a ball mill is the best choice when long term, stationary milling is justified by an operation.

5 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials In a nonreversible hammer mill with screen bars, shown in above figure, material is broken first by impact between hammers and breaker plates and then by a scrubbing action (shear

The ruggedly constructed, yet highly versatile WA Series and RC Series hammer mills are ideal for reducing a wide variety of blocky, abrasive and /or difficult to process materials to the exact required particle size for volume reduction, disposal or downstream processing. Our equipment manufactured for mining applications feature the most wear ...

Crushers and Their Types. A crusher is a multi dimensional machine which is designed to reduce large size materials into smaller size materials. Crushers may be used to reduce the size, or change the form of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in the case ...

A hammer mill stone crusher is different from other types of stone crushers in the way it works and the type of crushing it performs. Firstly, in order to crush and grind the material, a hammer mill stone crusher uses a number of hammers set on a revolving shaft inside a cylindrical chamber. We can fix the hammer to the center rotor, or the ...

The purpose of a hammer mill crusher is to produce a wide range of powder mixtures, wet or dry granulations. This manufacturing equipment also mixes various end associated products to make them useful. These machines are applicable in several avenues including, pharmaceutical, food processing, cosmetics, and chemical industries.

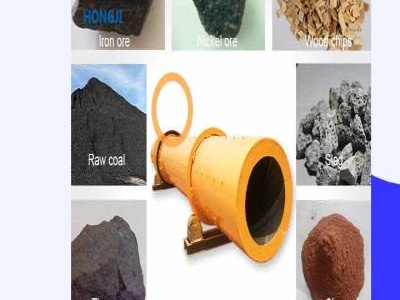

FORMER PRODUCT LINE. Doubleshaft hammer crushers are mainly used in the cement industry for the comminution of soft to mediumhard, but also tough and cohesive materials: Chalk, Limestone, Gypsum, Clay and Marl, and Coals such as Anthracite, Bituminous and Lignite. Crushing of the feed material is achieved by percussion, impact and shear forces.

The Komplet MT5000 mobile hammer mill is a tracked compact mill crushing machine, for a fact it is the smallest tracked hammer mill on the market today. It can be loaded via ramps on any truck or trailer, and transported with ease, thanks to its compact size and limited weight. The hammer mill crusher MT 5000, shatters, and pulverizes glass ...

employing steel materials such as hammers mill has revolutionize the processing of minerals in a small scale and large scale capacity. There are various types of machines generally used for size reduction of materials. These are Gyratory crusher. Jaw crusher, Ball mill, Burr mill and many others. Thus, of all the crushing

As experience shows, when one determines the energypower parameters of crushing and grinding processes by using the existing methods, the power of motors used in drives of existing crushers of various types often turns out to be excessive [10, 11].In this case, the drive will operate at a relatively low load (ratio of the power consumed by the working body of the machine to the rated motor ...

Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface. As the gap between the bowl liner and the mantle narrows, the rock is ...

There are two types of impact crushers: horizontal shaft impactor and vertical shaft impactor. Impact crushers are suitable for materials that are soft or easily cleaving from the surface. The crusher consists of a fast spinning rotor and beaters attached to the rotor. The feed is entering to the crusher from the top and crushing starts ...

These primary, singlestage, rugged impact crushers are great to use as a limestone crushing machine. The Reversible Nuggetizer® Crusher is built with heavyduty construction, and capable of handling 2,400 tons per hour—making it a reliable solution to limestone grinding. Williams Crusher's limestone mills and Pulverizers offer solutions ...

Hammer crushers are designed to crush brittle materials and break down conglomerates. The Hammer crusher HC 2х2 is laboratoryclass equipment designed to crush small batches of material with output up to 100 kg/hour.. Hammer crushers HC 5х2 and HC 5х5 are industrialclass equipment used in busy laboratories or in small and mediumsized production facilities.

Hammer Crusher Liming Heavy Industry. Operating principle of Hammer Crusher: In the hammer mill machine, the motor drives the rotor rotate at a high speed through the belt, .

grain mill 6NF4H 3IN1. rice hammer stationary. Production capacity: 150 kg/h. Grain Vibrator can clean the paddy Layers' Vibrator can separate the white rice into whole A grade rice and Half B Grade 3. Save the germ part of rice effectively 4. Separate whitening rice, broken rice, rice bran ...

A grain size reduction hammer mill for crushing corn (Zea mays L.) was designed depending on variety characteristics and by using computer aided design "ANSYS" software. Suitability of ...

At the bottom of the hammer mill, there is usually a screen fitted. This screen helps regulate the size of particles that can pass through, allowing for customization according to specific requirements. Additionally, some hammer mills also feature an airassist system which helps in discharging crushed materials and prevents clogging.

The 34″ x 24″ HD hammer mill is rated to accept feed of this type of looselyheld material at up to 20lbs per piece. The 24″ x 16″ HD hammer mill is good for up to 68 lbs per piece. We recommend that heavysectioned material such as whole starters/motors, small gas engines, or plumbing fixtures be limited to a lower weight.

High productivity: these machines are capable of fast and efficient crushing; Simple operation: designed with a mechanically simple single toggle, the jaw crushers are reliable and easy to maintain and repair.; Safe to operate: worker safety is kept in mind with full drive guard for occupational health and safety compliance, and dust extraction points to improve the operating environment.

Stedman Machine Company designs, develops and delivers highperforming, lowmaintenance, longlasting pulverizers and crushers perfect for demanding agricultural uses, including crushing aglime, processing animal feed, and milling grain and corn. Stedman Machine's reliable, durable cage mills and hammer mills are expertly engineered, sturdily ...

Cage mills are mechanical impact machines that crush, grind, or pulverize a variety of materials to specified degrees of fineness. They can be configured in two, four, and six row designs depending on the specific application needs, and are commonly used to pulverize industrial materials including coal and agricultural limestone.

Lump breakers are ideal most common deagglomeration applications, and where flowability is the goal. Industrial hammer mills and jaw crushers are the size reduction equipment of choice for processing large, blocky and/or abrasive materials. SchutteBuffalo offers an extensive line of lump breakers, industrial hammer mills, and jaw crushers. All models are custom configured to suit the user ...

Locking out and tag out. In terms of safety the electrical lockout of the machinery is the single most important step in this procedure. After the power disconnected, the circuit is tested. Puts personal locks on the tongs of power. This is to ensure that mill cannot be reenergized until the maintenance is complete.

ness ranging from 1 to 5, while a jet mill can grind materials with Mohs hardness as high as 10. High hardness materials become very abrasive; therefore, they are not suitable for highspeed hammer mills. In a typical jet mill, grinding action is caused mainly by particleparticle collisions, so wear to the mill's internals is less of an issue.

secondary crushers reduce the particle size of precrushed feed to 6 to 50 mm at much lower rates of throughput. Spring Swinging jaw Stationary jaw Hardened jaw faces Figure : Jaw crusher Gyratory crushers: A gyratory crusher may be looked upon as a jaw crusher with circular jaws, between which material is being crushed at some point at all ...