Food mills typically come with interchangeable discs with holes of varying sizes for puréeing different foods. If you want to make seedfree jams and berry sauces, look for a mill with an ultrafine disc (1 to millimeters). A fine disc (2 millimeters) will remove both skin and seeds from cooked tomatoes and create creamy soups and silky ...

منتج الأسمنت Uiltrafine Making Mill Ball Mill

Our particle size reduction equipment can be used for feedmilling, oilseed extraction or recycling. We are a onestop equipment solution for hammermills designed for demanding purposes. As the leading particle size reduction equipment company, consider our pellet mills, roller mills or flaking mills. Grinding Mills in Indiana.

I made super fine aluminum powder from foil, using my homemade ball mill! Here's where I got my motor:https://

With a wide range of ball mills worldwide, Retsch offers various suitable instruments. Apart from the planetary ball mills such as PM 100, PM 200 and PM 400, the new high energy ball mill Emax is especially suitable for colloidal milling down to the nanometre range thanks to the high speed and innovative water cooling system.

The Emax is an entirely new type of ball mill for high energy milling. The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time. faster and finer grinding than any other ball mill. speed of 2000 min 1 allow for ultrafast pulverization of the sample.

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications. Cooling, heating cryogenic grinding Mixer Mills

Industrial ball mills may be used to coarsely crush relatively large pieces of material, whereas labgrade ball mills are capable of finely milling glass to micron level and below. Socalled "high energy" ball milling can even be used to reliably grind the material into nanoscale particles. 4. Centrifugal Mill

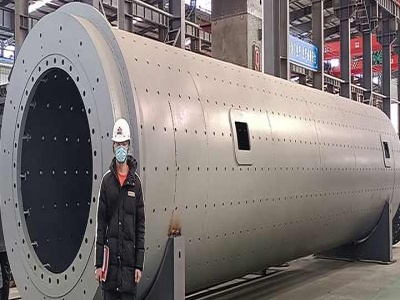

Steel Ball Mills Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800's. The basic construction of a ball mill is a cylindrical container with journals at its axis. The cylinder is filled with grinding media (ceramic or metallic balls or rods ...

In this video, I start by showing that homemade black powder doesn't burn very well if the ingredients are only ground separately with a coffee grinder. Then I explain how I made my own ball...

The ball mill consists of hollow cylindrical rotating shell made of steel lined with porcelain or high carbon steel plate. Upto 50 % of its volume, the shell is filled with balls made of steel or pebbles. The balls are of constant weight and varying size which depend on the amount of feed. The size reduction happens due to the

High temperature of the ball mill will affact the efficiency. 3 For every 1% increase in moisture, the output of the ball mill will be reduced by 8% 10%. 4 when the moisture is greater than 5%, the ball mill will be unable to perform the grinding operation. 5. The bearing of the ball mill is overheated and the motor is overloaded.

Give us a call as our inventory is always changing! Kentucky Mine Supply was established in 1917 in Middlesboro, KY to service the mining industry. In the early 1920s, we build a warehouse on our current location in Harlan, Ky and operated both until a fire wiped out the Middlesboro location. Even though Kentucky Mine Supply has "Mine" in its ...

See more reviews for this business. Best Machine Shops in Louisville, KY J R Machine Tool, Miles Machine Shop, Accurite Machine Manufacturing, CSC Machine and Gunsmithing, ARCO Engineering, Elite Welding Industrial Services, Bell Motor Service, Spencer Machine Tool, Hagmann Enterprises, ERL Commercial Marine.

DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h1000 g/h). For small to large scale operations, DOVE Ball Mills are supplied in 17 models, capacity range of ( TPH 80 TPH). With over 50 years experience in Grinding Mill Machine fabrication, DOVE Ball Mills as ...

The breakage mechanisms in stirred mills regardless of the mill orientation are typically described as abrasion and attrition (Gao and Forssberg, 1995, Sinnott et al., 2006, Wills and NapierMunn, 2006, Ye et al., 2010), or more simply "shear" breakage (Radziszewski, 2013).The dominant breakage mechanism in ball mills is generally considered to be impact breakage in the toe of the ...

1. Fill the container with small metal balls. Most people prefer to use steel balls, but lead balls and even marbles can be used for your grinding. Use balls with a diameter between ½" (13 mm) and ¾" (19 mm) inside the mill. The number of balls is going to be dependent on the exact size of your drum.

Small Ball Mills Canada. We sell Small Ball Mills from 2′ to 6' (600 mm X 1800 mm) in diameter and as long as 10″ (3000 mm) in length. The mills are manufactured using a flanged mild steel shell, cast heads, overflow discharge, removable man door, spur type ring gear, pinion gear assembly with spherical roller bearings, replaceable roller bronze trunnion bearings, oil lubrication ...

Raymond mills are replacing ball mills to process graphite powder May 7, 2020 How to improve the whiteness of calcium carbonate? May 7, 2020 How Many Mesh Can the Raymond Mill Grind? ...

Powerful black powder can be made with mill runs of between 2 and 4 hours. Use long drop cords. Unplug the cords at the electrical source, not at the ball mill, when you want to stop the mill. Run your mill remotely, outdoors, at least 150 feet away from people and inhabited buildings.

So, T. S. and Choi, W. S., "The Ultra Fine Grinding Mechanism of Inorganic Powers and Surface Modification in a Grinding Media Agitated Mill (1): Consideration on Specific Comminution Energy", Preprint of 36th Symposium on Powder Science and Technol., Japan, 170 (1998). Kwade, A., "Wet Comminution in Stirred Media Mills — Research and ...

Varied types/geometries of stirred mills have been produced by different manufacturers, and the comparison task has been accomplished for some of the technologies,, Tower mill vs IsaMill. However, the main drawbacks of these comparisons were the uncommon characteristics of the milling environment, such as media size. In this study, HIGMill and IsaMill, which were vertically and ...

Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually times the shell diameter (Figure ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 2040% water by weight.

Autogenous plus Ball Mill has been used very infrequently. When hard ores are encountered for extensive periods, 100 mm balls are added to the primary mill (#7). Semiautogenoussingle stage. These circuits are not a good choice for many orebodies because it is not logical to expect one machine to be as efficient on 150 mm ore as it is on 100 ...

Type CHRK is designed for primary autogenous grinding, where the large feed opening requires a hydrostatic trunnion shoe bearing. Small and batch grinding mills, with a diameter of 700 mm and more, are available. These mills are of a special design and described on special request by all Ball Mill Manufacturers.

The ball mill was rotated at 60 rpm (critical speed = rpm). Average feed size of mm of groundnut shell weighing about 100 g was fed into the ball mill. The ball mill is operated at different time (10, 15 and 20 min), ball loading (number of balls 4, 7 and 10) and RPM of the ball mill (60, 70 and 80 rpm).

Open Circuit Grinding. The object of this test was to determine the crushing efficiency of the ballmill when operating in open circuit. The conditions were as follows: Feed rate, variable from 3 to 18 T. per hr. Ball load, 28,000 lb. of 5, 4, 3, and 2½in. balls. Speed,

for innovative alternatives are crucial to making size reduction processes economically feasible. The optimization of ultrafine coal grinding performance using a laboratory scale stirred mill was approached in this research project. A series of kinetic stirred mill tests were conducted under

The calciner discharge of TiO2 white pigments from the sulphate process is ground batchwise in a planetary ball mill, varying the energy of comminution between 0 and times the earth''s ...

Easy chip control. High speed grooving, and drilling by 4 flutes mill. Thanks for NACHI unique flute geometry. Ridged and tough. Unique flute geometry and wide land on the cutting edge Tough cutting edge bring extreme high milling speed and excellent finishing surface. Series. X's mill Geo L9322.

Advantages of Ball Mills. 1. It produces very fine powder (particle size less than or equal to 10 microns). 2. It is suitable for milling toxic materials since it can be used in a completely enclosed form. 3. Has a wide application. 4. It can be used for continuous operation.

Taguchibased experimental design technique has been a major research area for making systematic approaches to understand the complex process of ball mill process parameters influencing on the synthesis of ultrafine silica sand monolayer degradation. To determine an optimal setting, Taguchi coupled optimization technique has been applied with a novel approach as there is no previous work ...

HGM80 Ultra Fine Grinder mill is mainly applied to noninflammable, nonexplosive and brittle materials with Mohs hardness under six. Such as calcite (calcite carbonate, calcium carbonate), chalk, limestone, dolomite, kaolin, gypsum, etc, totally more than 100 kinds of materials.

Ultrafine Ball Mill Ultrafine ball mill equipped with Nob to adjust the rpm and time required to grind the material. 50ml of bowl/pan is used as a container for the material to be grinded. Mechanical clamp are provided to hold the bowl so that the grinding material is intact so that spillage of material can be constrained.