February 08, 2017 · Archive · 0 . The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and ...

Gold Ball Mill House Ball Ball Mill في أستراليا

Factory Direct Sale Gold Processing Used Fine Grinding Machine 1200X3000 1200X4000 Raw Limestone Grinding Mill Gold Ball Mill. Jiangxi Hengchang Mining Machinery Manufacturing Co., Ltd. US / set ...

The number of impacts in primary ball mills are far more frequent but have less magnitude than those experienced in SAG mills. The increased frequency is due to the Increase in charge volume (35 40% versus 5 10%), higher mill speeds, and the larger number of balls per unit charge weight.

An increase of over 10% in mill throughput was achieved by removing the ball scats from a singlestage SAG mill. These scats are nonspherical ball fragments resulting from uneven wear of balls with included porosity. 30t of scats were removed from a total charge load of 70t. Surveying and modelling the mill revealed that the breakage rates

Ball mills and grinding tools Cement ball mills are typically twochamber mills (Figure 2), where the first chamber has larger media with lifting liners installed, providing the coarse grinding stage, whereas, in the second chamber, medium and fine grinding is carried out with smaller media and classifying liners.

During the runningin process, the amount of steel balls is added for the first time, which accounts for 80% of the maximum ball load of the ball mill. Steel ball sizes are Φ120㎜, Φ100㎜, Φ80㎜, Φ60㎜, Φ40㎜. For example, the 100150 tons ball mill has a maximum ball loading capacity of tons. For the first time, 30% 40% of ...

How a Ball Mill Work? for Gold, Diamond Mining, Cement, Quartz JXSC Mine Machinery Factory subscribers Share views 5 years ago The ball mill grinds ores and other materials...

This phenomenon is being exploited to improve mill productivity and ball consumption in the Henderson SAG mills. The opposite effect occurs in Climax 3 and 4 m ( and 13 ft) ball mills. These grind less than mm ( in.) ore that requires 76 mm (3 in.) top size balls.

Principle of Ball Mill: The size reduction in the ball mill is a result of fragmentation mechanisms (impact and attrition) as the balls drop from near the top of the shell. Mixing of feed is achieved by the high energy impact of balls. The energy levels of balls are as high as 12 times the gravitational acceleration.

1200 x 2400 MM (4 x 8 FT) BALL MILL, 30 kW, 2 TPHOverall Dimensions:6520x2850x2540 mmMaximum feed size: 25 mmMaximum Steel ball loading: tDischarge size: mmCapacity: tphSpeed: 32 rpmUsed, Refurbished or NewLow PriceNew Mills One Year Warranty on mill, 5 Year Warranty on Girth Gear!1000's of satisfied CustomersView our full ...

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles ...

1. Shortcylinder ball mill: The length (L) of the cylinder is less than twice the diameter (D) of the cylinder, that is, the ball mill with L ≤ 2D is a shortcylinder ball mill. Singlebin structure ball mill, which is mainly used for coarse grinding or primary grinding, has high efficiency. 2. Mediumlong cylinder ball mill, that is L = 3D. 3.

Turn the screw handle (RBM009) counterclockwise on the yoke (RBM) until the yoke is loose enough to slide left or right and be removed. Remove the lid (RBM) and place grinding charge (balls/rods) in the chamber. The charge should occupy approximately 4045% of the chamber.

Here's a stepbystep guide on how to set up a gold mining ball mill: Select the appropriate equipment: Choose a ball mill that is suitable for your mining operation. The ball mill should be able ...

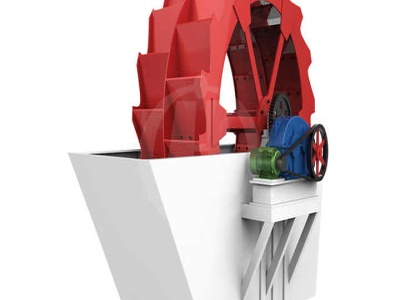

The ball mill machine is known as a ball grinding machine. It is a wellknown ore grinding machine and is widely used in mining, construction, and aggregate application. JXSC started manufacture the ball mill grinder since 1985, supply globally service includes flow design, manufacturing, installation, and free operation training in mining ...

Contact name:lily Whatsapp: + email:lily420677 Rod mills and ball mills are the two most commonly used equipment in grinding equipment.

The sprawling home at 28 Strathfield Ave also broke the street record that was previously set in 2017 by 5 Strathfield Ave by 320,000. The result was almost to be expected, with 10 contract requests and 102 inspections during the five week campaign.

The Function of a Ball Mill . To perform its functions, the ball mill operates on the principle of impact and attrition. This principle entails that the balls are dropped from near the top of the shell in order to bring about size reduction impact. The major components of the ball mill include a shell that is hollow and is suspended on its axis ...

The Golden Ball is a pub in the Bishophill area of central York, in England. The first record of the pub was in 1773. The core part of the building was constructed in the early 19th century. In 1883, a house for the publican was constructed by Benson Minks, adjoining the pub. The pub was sold to Braime's Brewery in 1884, and this in 1902 was ...

The advantages and disadvantages of ball mills. 092120; 3,141 Views; icon 0; Because the method used to grind the fine material in the beneficiation equipment was an early mine mill, and later developed into a ball, there is a finer with a larger output, and the speed of replacement is very fast.

The horizontal design makes it easy to operate and maintain, and it is suitable for both wet and dry grinding. 2. Vertical Ball Mill. A vertical ball mill is a type of ball mill where the barrel is vertical instead of horizontal. It is designed for fine grinding of materials, and it is usually used in laboratory or smallscale production.

Introduction Ball mill is the key machinery for further smashing broken materials. Ball mill is suitable for crushing various ores for rotary kiln. Ball mill is widely used in many sectors like mineral processing, building materials and chemical industry.

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum 'chunk size', product size as P80 and maximum and finally the type of circuit open/closed ...

We have a wide range of inhouse built and imported ball mills. Both batch and continuous feed mills are available with steel, rubber or ceramic replaceable lining. Custom builds are available, contact us for more information. Sort by Batch Ball Mill 50L BBM50 7,000 Batch Ball Mill 100L BBM100 10,000 Batch Ball Mill 200L BBM200 15,000

Generally, filling the mill by balls must not exceed 30%35% of its volume. The productivity of ball mills depends on the drum diameter and the relation of ∫ drum diameter and length. The optimum ratio between length L and diameter D, L: D, is usually accepted in the range

Ball Mill Sole Plate. This crown should be between .002″ and . 003″, per foot of length of sole plate. For example, if the sole plate is about 8′ long, the crown should be between .016″ and .024″. Ball Mill Sole Plate. After all shimming is completed, the sole plate and bases should be grouted in position.