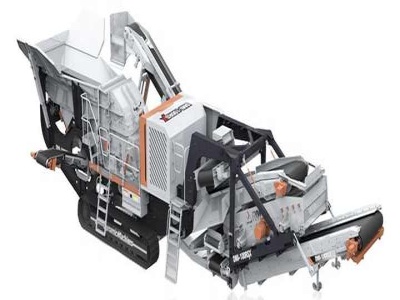

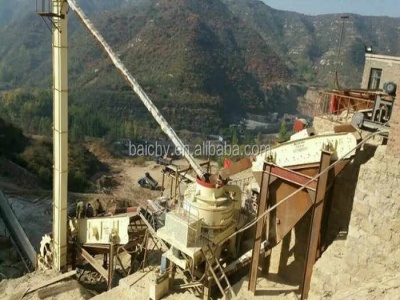

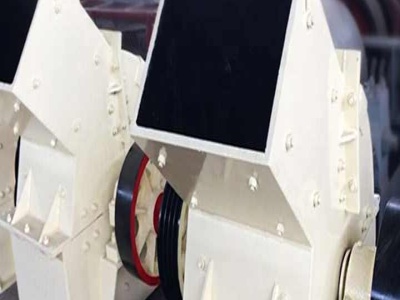

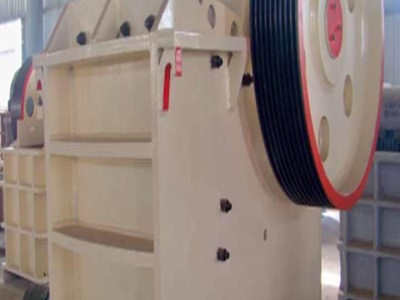

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.

Crement Ball Mill Construction PDF

Want to continue learning about engineering with videos like this one? Then visit:https:/// Want to teach/instruct with the 3D models shown...

Removal of attached mortar. The primary goal of ball mill processing is to improve the characteristic properties of RCA by effectively removing adhered mortar without developing minor cracks on the aggregates' surface. The percentage of attached mortar removal was calculated using Table 5 summarises the findings.

The bottom parameters used in ball milling design (power calculations), rod mill or any tumbling mill page is; material to be ground, property, Bond Employment Card, bulk density, specific density, wish mill tonnage capacity DTPH, operates % stables or pulp density, feed extent as F80 and maximum 'chunk size', product size as P80 and maximum and ending the class of circuitry open/closed ...

Cement as construction material: Cement used in construction is characterized as hydraulic or nonhydraulic. Hydraulic cements (, Portland cement) harden because of hydration, ... Ball mill . Ball mill. IJSER. International Journal of Scientific Engineering Research, Volume 7, Issue 5, May2016 89 ...

Cement production is the basic construction . ... air is obtained by the example of a closed circuit cement ball mill of the Belgorod cement plant. ... / WEBWDWTBB063 ...

Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum rotates approximately once every couple of seconds. The drum is generally divided into two or three chambers, with different ...

Cement Silo Ball Mills Hopper Truck Fly Ash Conveyor Belt Cement Iron Oxide Material Clinker Limestone Dust Extractor Chimney Silica Plaster Freight Train Bagging Clay Hopper Other Raw Materials Hopper P15 P7 P8 P9 P7 P10 P7 P12 P11 P19 P21 Bearing Units P23 P23 P24 P25 Raw Materials Firing Finishing 3 4. 5. 6

Download PDF. Grinding Aid Effectiveness in Cement Ball Mill Web: Email: bulawali, ali LinkedIn: Ali Bulawali Date: Sep 2016 of grinding balls (Grinding Media) ranging from 2 cm to 90 cm or 100 cm diameter, in addition to large surface area for different sizes of grinding Balls the grinded substance ...

Cement is an extremely important construction material used for housing and infrastructure development and a key to economic growth. Cement demand is directly associated to ... Combinations of milling techniques including ball mills, roller mills, or roller presses are often applied to ground clinker with additives in cement mill. The finished ...

V — Effective volume of ball mill, m3; G2 — Material less than in product accounts for the percentage of total material, %; G1 — Material less than in ore feeding accounts for in the percentage of the total material, %; q'm — Unit productivity calculated according to the new generation grade (), t/(). The values of q'm are determined by ...

Project Description. This project won an award in the 2019 AIA/AAH Healthcare Design Awards FROM THE AIA: The new VA Palo Alto (VAPA) Polytrauma and Blind Rehabilitation Center is one of only five polytrauma centers in the country designed specifically to serve and enhance the patient rehabilitation experience of polytrauma, blind and visually impaired veterans.

Based on his work, this formula can be derived for ball diameter sizing and selection: Dm <= 6 (log dk) * d^ where D m = the diameter of the singlesized balls in = the diameter of the largest chunks of ore in the mill feed in mm. dk = the P90 or fineness of the finished product in microns (um)with this the finished product is ...

The length of the mill is approximately equal to its diameter. Principle of Ball Mill : Ball Mill Diagram. • The balls occupy about 30 to 50 percent of the volume of the mill. The diameter of ball used is/lies in between 12 mm and 125 mm. The optimum diameter is approximately proportional to the square root of the size of the feed.

Closed Circuit Grinding VS Open Circuit Grinding. The simplest grinding circuit consists of a ball or rod mill in closed circuit with a classifier; the flow sheet is shown in Fig. 25 and the actual layout in Fig. 9. This singlestage circuit is chiefly employed for coarse grinding when a product finer than 65 mesh is not required, but it can be ...

Jan 08, 2013 · ... The PFEIFFER MPS vertical roller mill ideal for combined grinding and ... cement plant operation handbook pdf; anpara thermal power plant ppt; Fuller Company, LM vertical mill of . Crusher Operation Manual ... vertical roller mill operation manual for coal mill . Loesche Coal Mill Operation ...

Ball Mill Ball mill is the key equipment for grinding materials after crushing and screening. It is also commonly used in grinding equipment. Dry Ball Mill: I. It is mainly used in refractory, fertilizer, cement and glass industries; II. The dry ball mill has strict requirements on the moisture content of the raw ore, and the material must be dry;

CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volume.

Our ball mills for cement grinding deliver high grinding efficiency with reduced energy consumption and low maintenance. 4000+ references worldwide. ... PDF (1031KB) Download. Ball mill trunnion replacement_data sheet. English. PDF (514KB) Download. STANEX diaphragm for ball mills. English. PDF (895KB)

of 24 BALL MILL OPERATION GUIDELINES January 2008 ffContent Prerequisites P1 Material specifications = raw mills p. 1 P2 Material specifications = cement mills p. 2 P3 Mill internals conditions = liners p. 3 P4 Mill internals conditions = diaphragms p. 4 P5 Ball charge p. 5 P6 Mill kW p. 6 P7 Bucket elevator kW p. 7

Portland Cement Manufacturing Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of ... accomplished during grinding in ballandtube mills or roller mills. While thermal energy for drying can be supplied by exhaust gases from separate, directfired coal, oil, or gas burners ...

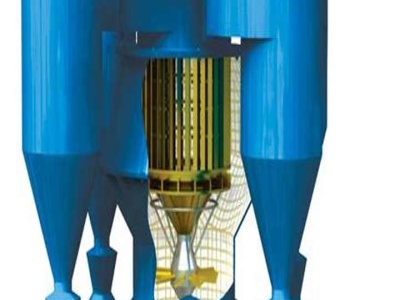

Construction of Ball Mill. The ball mill consists of a hollow metal cylinder mounted on a shaft and rotating about its horizontal axis. The cylinder can be made of metal, porcelain, or rubber. Inside the cylinder balls or pebbles are placed. The balls occupy between 30 and 50% of the volume of the cylinder. The diameter of the balls depends on ...

Commercial Sidewalk Encroachments (including Outdoor Eating Areas) Process Document (PDF, 135KB) Development and Construction Near Streams ... (PDF, 8MB) Municipal Fence Code (PDF, 433KB) Trash Enclosure Area Guidelines . Back to top. City Hall. 250 Hamilton Avenue Palo Alto, CA 94301. General City Information (650) . City Service Feedback.

Ball Mill Sole Plate. This crown should be between .002″ and . 003″, per foot of length of sole plate. For example, if the sole plate is about 8′ long, the crown should be between .016″ and .024″. Ball Mill Sole Plate. After all shimming is completed, the sole plate and bases should be grouted in position.

Ball mills Ball mills are used for dry and wet grinding of different materials such as cement materials, cement, lime, and ceramic materials. PSP Engineering has continuously refi ned the design of its ball mills. Horizontal ball mills have become a reliable part of grinding plants Main characteristics of ball mills seated on shoetype bearings

The proven classical option for cement grinding. Whether employed as a twocompartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust and reliable alternative for cement and granulated blast furnace slag grinding. Find out more

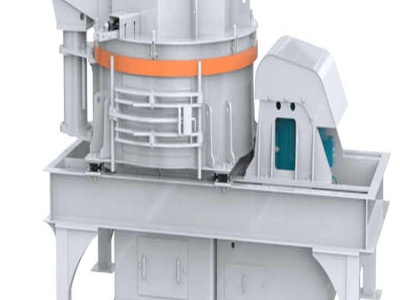

The grinding process in ball mills and vertical roller mills is fundamentally different [15]. Following are advantages of VRM over Ball Mills with reference to these issues: • Strong drying ability Inlet hot air from Kiln can dry materials with 20% water content. (max moisture 20% vs. 3% in ball mill) [15], [16]. •

The Ball mill is one of the most important equipment in the world of chemical engineering. It is used in grinding materials like ores, chemicals, etc. The types of ball mills: batch ball mill and continuous ball mill with different grinding media and different design depend on the nature of the input material and the nature of the output which I need.

The purpose of this article is to discuss modern flour mill design and construction methods. This paper will discuss planning, lifesafety considerations, food compliance regulations, and building ...