DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h1000 g/h). For small to large scale operations, DOVE Ball Mills are supplied in 17 models, capacity range of ( TPH 80 TPH). With over 50 years experience in Grinding Mill Machine fabrication, DOVE Ball Mills as ...

Hai Feng Grinding Ball Mill ModelX160

Ball mill load refers to the total materials inside the cylinder, including ore, grinding media, water, mineral pulp, etc. Understanding the load status accurately is an important basis for the ...

This paper compares the performance of a 25/75 pebble/ball (volume ratio) composite charge to ballmilling, under conditions typical for a ballmill in SABC circuits, a large ball top size ...

hai feng grinding ball mill modelx160; Send us a message. ... The finite element method is used to build the model of the × overflow type ball mill. And then modal analysis of oversize ball mill tube is carried out by ANSYS workbench, which leads to the intrinsic frequency and model of vibration of 2700 4500 Ball Mill ...

This study investigated ultrafine coal grinding performance of four low to moderatecost grinding media in a laboratory stirred mill. Kinetic grinding tests showed that silica beads generated the finest product size with a P 80 of μm from a feed size of μm while having a specific energy (SE) input of 309 kWh/ton. Nonetheless, the ...

The optimization of processing plants is one of the main concerns in the mining industry, since the comminution stage, a fundamental operation, accounts for up to 70% of total energy consumption. The aim of this study was to determine the effects that ball size and mill speed exert on the milling kinetics over a wide range of particle sizes. This was done through dry milling and batch grinding ...

CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volume.

Abstract. A particle size reduction model has been developed as the first component of an upgraded ball mill model. The model is based on a specific energysize reduction function, which ...

As one of the machines widely used in mining, a semiautogenous grinding (SAG) mill can significantly improve the roughing efficiency of rock. But the SAG mill still faces the obstacles of significant energy consumption and empirical operation parameters. In order to obtain the optimal operation parameters of a SAG mill, in this paper, the discrete element method (DEM) is used to simulate the ...

Open Circuit Grinding. The object of this test was to determine the crushing efficiency of the ballmill when operating in open circuit. The conditions were as follows: Feed rate, variable from 3 to 18 T. per hr. Ball load, 28,000 lb. of 5, 4, 3, and 2½in. balls. Speed,

Optimum filling ratio. U= (volume of powder in the mill)/ (volume of voids in the charge): between 60% and. 110%, optimum around 90%. In practical terms, material level should equal ball level in the first compartment. In practical terms, material level should be higher than ball level in the second.

Investigating ball mill grinding from the kinetic point of view, the authors studied the effect of properties of samples and feed weight on grinding rate constant of first samples were ...

QI GONG JI XIAN LIN FENG QI YONG . Overview mill grinding equipment . prepared by high energy ball milling 198 5 2 1 Preparation of pure . oxide mill li shan tiawan ? Grinding Mill China

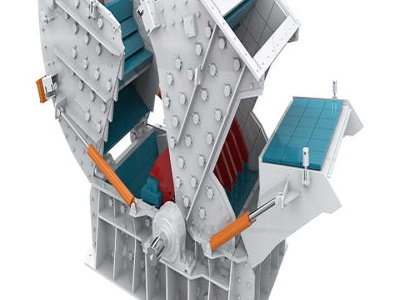

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles ...

The effect of the material ball ratio to the stirring mill's grinding ef ciency and speci c productivity under a 90% lling rate of medium was investigated, a 15mm ball medium size, a 50% grinding ...

Compared with the original twostage ball milling process, the cost of grinding power consumption is significantly reduced by about %, which provides a reference for the subsequent research on energy saving and consumption reduction in ball milling operations. The optimal grinding parameters were determined to be grinding concentration of ...

Levent Ergun. Hakan Benzer. In this paper, a new approach for the calculation of the power draw of cement grinding ball mills is proposed. For this purpose, cement grinding circuit data including ...

For beneficiation of a particular iron ore the emphasis is usually to develop a cost effective flow sheet incorporating necessary crushing, grinding, screening and beneficiating techniques which are necessary for the upgrading of the iron ore. A typical flow sheet for iron ore beneficiation plant is shown in Fig 1. Our services

There are three basic structures among the coal grinding, t: AirSwept or Wet Tumbling Ball Mill, RollerRace or BallRace Mill and Hammer or Impact Mill [7] [8][9][10]. The type of the mill and ...

A total scaleup method for planetary mill is discussed in this section. All parameters ( d M, h and R) of the basic planetary mill were scaledup as t p times to investigate the effect of the scaleup ratio on E i. The scaleup ratio was changed from to ( V M = 170 36 650 cm 3; n B = 80 17 496).

Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually times the shell diameter (Figure ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 2040% water by weight.

The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easytouse counterweight which compensates masses up to 8 kg. It allows for grinding up to 220 ml sample material per batch. The extremely high centrifugal forces of Planetary Ball Mills result in very high pulverization energy and therefore short ...

The effect of ball size on copper powder particle morphology in drytype milling was studied using a planetary ball mill. Spherical copper powders were obtained by ball milling at a high rotation ...

Mill Type Overview. Three types of mill design are common. The Overflow Discharge mill is best suited for fine grinding to 75 106 microns.; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 250 microns.; The CenterPeriphery Discharge mill has feed reporting from both ends and the product discharges ...