circuit by further crushing 35% of SAG mill fresh feed. Such figures would represent yearly additions of kt in copper and 250 kg in gold productions. Keywords: grinding; SAG; preprocessing; copper ore 1. Introduction A steady increase in the world copper demand is predicted for the next 25 years of,

SAG Mill Coppers

For instance, at Lornex Mining, one of the most successful SAG installations, the ball load varies normally from 67% by volume of the mill; the ball makeup consists usually of 80% 4inch diameter balls and 20% 5inch diameter balls. The ratio of the larger balls is increased when the mill is processing hard ore and decreased with soft ore.

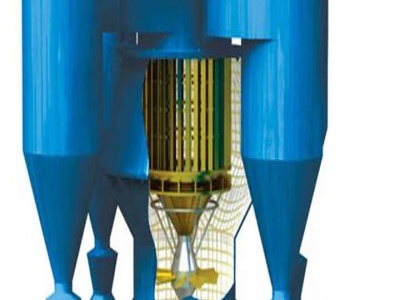

Working Principle of a SAG Mill. The rock and grinding media are placed in the mill and rotated, causing the grinding media to tumble and crush the rock into smaller pieces. The mill operates in a closed circuit with screens that size the ore and send it back to the mill for further grinding. The product from the mill is then sent to a cyclone ...

25 to 40 t/h for copper porphyry SAG Ball Mill duty In Single Stage SAG duty, the approximate capacity reduces to only 8 to 13 TPH for gold ore duty. The autogenous mill itself is a coarsegrinding device, consisting of tumbling drum with a 25% to 40% volume filling of ore. Metallic or manufactured grinding media is not used.

In this training module, we'll cover the workings of a semiautogenous grinding mill, or SAG mill, that's designed to be the first stage of a grinding circui...

In the mining, some precious metals found are like gold, silver, nickel, and copper etc. Ball Mills: Ball mill is a fine grinder. A horizontal or vertical rotating cylinder which is filled partially with the balls of ceramics, small rocks and balls made from stainless steel. The ball charge of a SAG mill is about 29% to 30%. By friction and ...

Table 4: JK MRC Comminution Parameters. SAG milling in closed circuit with a vibrating screen followed by a ball mill. OMC ARM FDW. No. of Units 1 1 1. Diameter m Length m 4 ...

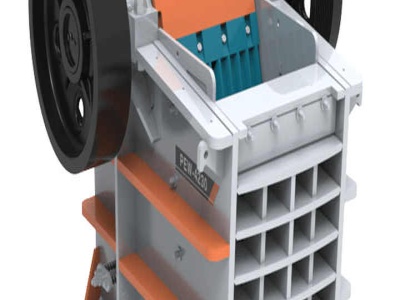

copper produced in the United States originated from flotation (Daniel E. Edelstein, Copper Commodity Specialist, Geological Survey, written commun., March 20, 2012). ... The crushed ore is transferred to a semiautogenous (SAG) mill or ball mill where the ore is further reduced in size. Water is added to the ball mill, in which a slurry ...

A total of 120 t of Cristalino ore was prepared and sent to CIMM, where it was crushed and screened prior to grinding tests. The processing equipment included a m (8′) diameter by m (2′) length AG/SAG mill equipped with a 20 kW motor, a cone crusher, a m (3′) diameter by m (4′) length ball mill equipped with a 15 kW ...

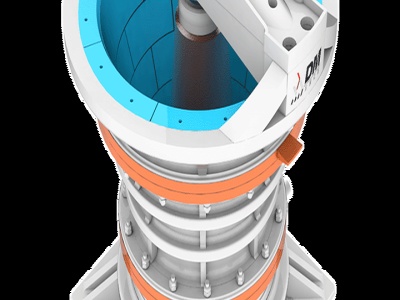

For this expansion project, Kinross selected ABB to provide a 26 MW gearless mill drive system (GMD) for the mine's 40 ft SAG mill, as well as other drives, electrical infrastructure equipment and a longterm service agreement (LTSA). Joel Desmeules, Construction Manager for the SAG mill, at Kinross. "We are pleased with the ABB team's ...

The amount of copper in copper sandstones and slates varies from 1 to 6%, in sulfide coppernickel ores from to %, in copperpyrite ores from to 3%, and in copperporphyry ores from to %. Uptodate technological solutions, effective reagent flotation schemes, highperformance equipment, and integrated approaches when choosing ...

Considering the continuous increase in production costs and resource optimization, more than a strategic objective has become imperative in the copper mining industry. In the search to improve the efficiency in the use of resources, the present work develops models of a semiautogenous grinding (SAG) mill using statistical analysis and machine learning (ML) techniques (regression, decision ...

DESIGN OF THE 40 FOOT DIAMETER SAG MILL INSTALLED AT THE CADIA GOLD COPPER MINE By R. Dunne1, S. Morrell2, G. Lane4, W. Valery3 and S. Hart5 1Newcrest Mining Ltd, 2SMCC Pty Ltd, 3JKMRC, 4GRDMinproc Ltd, 5Newcrest Mining Ltd Cadia Hill Gold Mine, Australia ABSTRACT

ABB has partnered with Kaz Minerals to supply GMDs for the company's Aktogay and Bozshakol copper mines in Kazakhstan, both of which are expected to process 25 Mt/y of ore. ... 28 MW SAG mill and two 28 ft, 22 MW ball mills to the project in order to meet the challenge of highercapacity production coupled with low ore grades. Learn more. GMD ...

Compañía Minera Antapaccay (a Glencore Company) has constructed and is operating a concentrator with one of the largest volumetric capacity SAG mill in the world at its Antapaccay copper mine located in the Cusco region in southern Peru.

January 2017 Authors: Mehdi Hadizadeh University of Tehran Akbar Farzanegan M. Noaparast University of Tehran Abstract and Figures Successful control of SemiAutogenous Grinding (SAG) mill...

SANTIAGO, Oct 24 (Reuters) Canadian miner Teck Resources has scrapped a previously submitted environmental permit application to expand a mill at its Quebrada Blanca copper mine in Chile in ...

Fluorled JV Awarded Contract to Install Grinding Mill at Grasberg Copper and Gold Mining District in Indonesia. ... With the additional SAG mill, the milling capacity will be approximately ...

Due to its strong lifting capacity and excellent grinding performance, the trapezoidal liner is widely used in the SAG mill. The structure of the trapezoidal liner is shown in Fig. 1, the main dimensions are: dip angle (tau), length of the top edge (L) and height (h).Dip angle (tau) determines the trajectory of the mediums in the SAG mill, which directly affects the impact speed and ...

Dunne et al. (2001) state the initial design of the Cadia Gearless Mill Drive called for 20 MW at a RPM rated speed. The tent diagram assuming volumetric loadings of 13% balls and 25% total ...

Copper Mountain's concentrator was commissioned in May 2011. The circuit consists of a 34' x 20' EGL SAG mill, a Raptor 900 pebble crusher and two 24' x 39'6" ball mills. Each mill is equipped with a 2 x 8500 HP dual pinion drive system. The plant was designed to process 1585 mtph of SAG feed.

The purpose of this study is to investigate and simulate the optimal operating conditions of a ball mill in a copper processing plant. The actual operating conditions in the intended mill are ...

The product from the SAG mill is further reduced in size using pebble crushers and ball mills. Hence, typical gold or copper ore requires between and kWh per ton of energy to reduce the particle size. Considering a typical mining operation processes 10,000 to 100,000 tons per day the energy expenditure in grinding is 50 percent of the ...