Ball mill 200 mesh ~ 37 mesh Raymond mill 340 mesh ~ 90 mesh Vertical mill 325 mesh ~ 80 mesh . I ball mill the contents for 23 weeks,and I can get powder 400500 mesh. Tanzania ball mill of 500 mesh

Ball Mill 400 Mesh Size

40 mesh screen (about mm) while most of the product of a fine grinder will pass 200 mesh screen ( mm). Ultrafine grinders will accept a feed of a few mm in size and reduce it to a product of sizes in the range 1 50 m. Cutters will deliver particles of definite shape and size, typically a few mm in length.

P = The 80% passing size of the ground product in µm F = The 80% passing size of the feed in µm . The test is a closed circuit dry grindability test performed in a standard ball mill. It can be performed at mesh sizes ranging from 28 mesh to 400 mesh. The normal finishing size is 100 mesh. Feed Sample Requirements 10 kg of minus 6 mesh * Bond ...

For over 35 years Laval Lab Inc is the onestop specialist for size reduction of all types of materials. ... Pulverisers, Disc Mills, Grinders, Planetary Ball Mills: 40 mm < 300 m: Knife Mill: 1,400 mL: SS: Fritsch P11: 20 mm < 100 m: Disc Mill: 150 kg/h: User selectable: Fritsch P13: 20 mm: 50 m: Disc Mill: 150 kg/h: User selectable: Fritch ...

The ball mill work index laboratory test is conducted by grinding an ore sample prepared to 100% passing mm (6 mesh) to product size in the range of 45150 µm (325100 mesh), thus determining the ball mill work index (Wi B or BWi). The work index calculations across a narrow size range are conducted using the appropriate laboratory work ...

Other product characteristics can be addressed such as the size at the infeed, bulk density, flowability, hardness, moisture content, heat sensitivity, toxicity and even explosivity. Milling selection: Hammer and screen mill. Check to see if a lowcost technology can meet the requirements, Ozsoylu suggests.

Before choosing a grinding mill, you need to know the size of your material and the size of the finished product you need, so that you can choose a suitable mill. Equipment. Feeding size. Discharging size. Ball mill. 04mm. 545 μ m. Micro powder roller mill. 010mm.

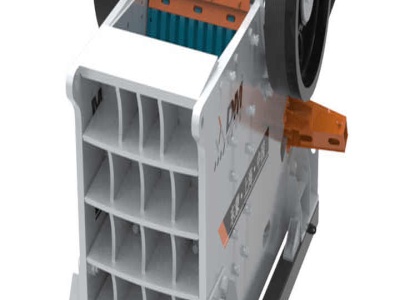

Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually times the shell diameter (Figure ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 2040% water by weight.

An inefficient ball mill is a major expense and could even cost you product quality. The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance. With more than 4000 references worldwide, the FLSmidth ball mill is proven to do just that.

1. Steel Balls. Steel balls are one of the most widely used grinding media in cement ball mills, their diameters can range from 20mm to 120mm according to different grinding requirements. In a cement ball mill, generally, φ50100mm steel balls are used in the coarse grinding chamber, φ2050mm steel balls are used in the fine grinding chamber.

Newermodel Gilson shakers are equipped with an easytouse clamping system to secure and lock sieves in place. All sieve shakers come with a mechanical or digital timer, except the 8in Wet/Dry Vibrator. Tapping enhances performance through aggressive circular actions and repetitive twoway tapping of the sieve stack.

The RoTap® is the required test sieve shaker in many industrial specifications, according to ASTM Standards. RoTap® Sound Enclosure Cabinet: that is designed to be used exclusively with the RoTap ® Sieve Shaker, reduces operating noise levels from approximately 85 dB to 78 dB. The cabinets are fabricated with 18 gauge steel and a 1 ...

Per Hour Fineness of 100 to 325 Mesh: Bhm20: Bhm25: Bhm32 Std. . 400: 600 : 900: 1500: Graphite: 150: 300: 600: 900: 1500: Gypsum: 200: 400: 700: . Ball Mill. IIPR Mini Dal Mill. Tumble finishing Wikipedia, the free encyclopedia . (120220 then 400600 mesh), before the (optional) use of a prepolishing compound .

Why Choose US. Shanghai Clirik Machinery Co.,Ltd is the professional dolomite grinding mill and Crusher manufacturer, devoted to the dolomite process more than 10 can supply Vertical Roller mill,Raymond Mill,Ball Mill,Ultrafine mill,Hammer mill used for dolomite grinding. And our company have gotten the ISO9001:2008, and the HGM ...

It is supplied in several mesh sizes under the trade name SilCoSil (or Supersil): SilCoSil #75 200 mesh #63 270 mesh #52 325 mesh #38 400 mesh The mesh size is very important, both in clays and in glazes. The mesh size affects the effective reactivity of the silica (finer is more reactive), which determines how much silica is changed to the ...

Similarly, the net efficiency of the ball mill will have the same value, in this case, for any monosize feed to the ball mill at any other size distribution, that is, any other X 50 of the product, ... The specific surface of the minus 400 mesh material was determined by gas adsorption method, using krypton as the adsorbate. Since the ...

The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all other ball mills designated as 5′ x 5′ where ...

Grinding Studies. Two kinds of mills, BBM and LBM, were used to achieve the desired P 80 passing percentage of 150 μm with an acceptable range of hematite liberation (> 75%) at optimum grinding time. The BBM is a standard ball mill having a length and diameter of 300 mm × 300 mm with smooth liner as shown in Fig. rotating drum is attached to a gearbox and has adjustable speed knob.

Unique relationship (eqn. 16) between median size and fines produced when dolomite is wet ground in a ball mill alone and in an admixture with hematite, showing the invariant grinding paths. 20 E 10 E a ~ 0 7 c 08 0 'v v 114 03f 02~ Hematite ( Wet Ground) 0 10 20 30 Fines Produced, 7. 400 200 100 mesh Feed Composition (x Vol ...

The Mixer Mill MM 400 is a true multipurpose mill designed for dry, wet and cryogenic grinding of small volumes up to 2 x 20 ml. It mixes and homogenizes powders and suspensions with a frequency of 30 Hz within seconds unbeatably fast and easy to operate.

The dry feed of a ball mill circuit is 300 t/h. The power at the pinion of the ball mill is 1800 kW. F80 = 80% passing size of the circuit feed, in microns = 2500 um. P80 = 80% passing size of the circuit product, in microns = 225 um Solution. Work Input (Energy input): W= (1800 kw)/ 300 t/h= kwh/t. Then. WI = Work Index of this circuit

If it is desired to find the effect of balls grinding 20mesh ore and the mill is loaded with 20mesh material, the grinding time should be infinitely short, because fine particles are made as soon as the mill starts and if the run continues the test is of the comminuted products of the 20mesh sample rather than that which was supplied for the ...

Determination of the requested fineness by choosing the mesh width of the sieves ( mm). The achieved particle size spectrum favors the subsequent fine grinding by means of ball mills and roll refiners.

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications. Cooling, heating cryogenic grinding.

The capacity, or throughput, of a ball mill is directly linked to particle size of the ball mill discharge. For example, it takes approximately 3 times as long to achieve 200 mesh grind as it does to achieve 65 mesh grind. Establishing a commercial liberation size is critical when designing and engineering your grinding circuit.

Fine Grinding Mill. Grinding material to 20400 mesh,It is your right hand in the field of industrial milling such as desulfurization ... coal mill, 200 mesh, D85, 45tph. Output size: 200 mesh, D85. LM220M, coal mill, 200 mesh, D85, 45tph. ... MTW European Grinding Mill MW Micro Powder Mill Raymond Mill Hammer Mill Ball Mill

n n FOR VERTICAL ROLLER MILLS Loesche n. situations in that,not only does a mill operate at generally lower vibration levels under LM Master control reducing wear on gearboxes and other major components but the continuous monitoring of the mill process allows for Loesche is launching its new LM Master for advanced vertical roller mill,manual book coal mill cement plant legendhotelinloesche ...

The best preparation scheme is: flake graphite (50 mesh) 20 g, ball milling time 5 h, ball milling speed 410 r/min, aluminum particle diameter ratio 200 mesh:500 mesh = 1:, aluminum total mass g, steel sand particle size mm: mm = :1, steel sand total mass g. •

Retsch revolutionalizes grinding with an entirely new type of mill: the High Energy Ball Mill Emax. 1923 The company's first own piece of laboratory equipment is developed, a mortar mill, which becomes known as the Retsch Mill and is synonymous with the concept of easier and better laboratory work. 1959

The iCon i150 and i350 are, for a small miner, high capacity gravity concentrator designed for feed throughputs of 1 to 15 TPH, for feed material finer than 2 mm (10 mesh) in size. The highG cones operate at feed pulp densities of 60% to 65% solids (by weight) and as low as 5%, with have excellent recovery efficiencies for high specific ...