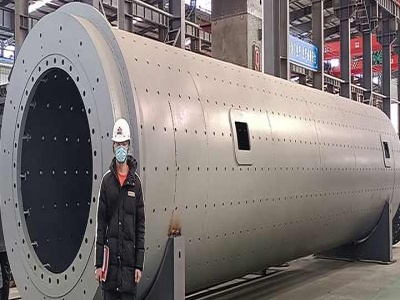

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles ...

C Est Quoi Sag Mill

The biggest characteristic of the sag mill is that the crushing ratio is large. The particle size of the materials to be ground is 300 ~ 400mm, sometimes even larger, and the minimum particle size of the materials to be discharged can reach mm. The calculation shows that the crushing ratio can reach 3000 ~ 4000, while the ball mill's ...

Advantages of c est quoi sag mill. london album discography, part 3 bsnpubslondon album discography, part 3 tw 91000/sw 99000 international series by david edwards, patrice eyries, mike callahan, randy watts and tim neely2018 fifa world cup the 2018 fifa world cup was the 21st fifa world cup, an international football tournament contested by

matter. ( ˈmætə) n. 1. that which makes up something, esp a physical object; material. 2. substance that occupies space and has mass, as distinguished from substance that is mental, spiritual, etc. 3. substance of a specified type: vegetable matter; reading matter. 4. (sometimes foll by: of or for) thing; affair; concern; question: a matter ...

C'est un travail très dangereux. Tu peux obtenir à peine un à deux colis de matériaux récupérés. Chaque jour, tu peux avoir 4000 ou 5000 FCFA", révèletelle.

varying it as the mill water addition rate changes. Loveday/Barratt Model Brian Loveday published a simple SAG mill model (Loveday, 1978) of the form in Equation 2. The equation uses mill dimensions (inside the liners), the density of the mill charge and an empirical "power number" that encapsulates the mill speed and volumetric filling.

n n Saisie intuitive â€" Wikipédia n. Principe de fois la touche 3 pour sélectionner le groupe D E F (D et F ne peuvent venir après SAG,du moins dans des mots du dictionnaire),c'est à dire 7243,soit seulement 4 pressions au écessité de procéder par coton mill in yavatmalraymond coton mill in yavatmal piedra lÃnea ...

1. SAG mill is the primary tool for grinding. SAG mill is used before the other mills. Ball mill is a secondary, and it is used after the SAG mill. 2. SAG mill breaks the raw material into pieces for the further grinding. Ball mill is used to grind the pieces of raw material into. powderlike structures. 3.

The GolEGohar iron ore concentration plant located in southeast Iran. Three 9 m × m AG mills are used in parallel in a dry operation to grind a feed nominally passing 32 cm, which is the product of a gyratory SAG mills is driven by a 4023 hp motor and runs at a constant (12 rpm rotational) speed (, 85% of critical speed) in one direction.

In mining, tailings or tails are the materials left over after the process of separating the valuable fraction from the uneconomic fraction of an are different from overburden, which is the waste rock or other material that overlies an ore or mineral body and is displaced during mining without being processed.. The extraction of minerals from ore can be done two ways: placer ...

We have an application in a SAG Mill where we have installed an electronic ear in order to listen the noise produced by the balls falling to the bottom of the mill. Our idea is to convert the amplitude and frequency of noise to a 420mA signal (or something else) in order to determine if the ball is crushing the mineral or the mill lining.

Three things to consider for your SAG Mill Feed Chute downtime, safety and access. When it comes to servicing or maintaining a grinding mill, many customers focus on the mill itself rather than all its related components. One such component is the feed chute, which is often overlooked. However, it is a key part in the grinding process that ...

Sociologie du corps. e corps Introduction: Le corps c'est aborder les liens entre le corps et l'environnement. Globalement on sollicite notre corps dans n'importe quelle position. Qu'est ce que le corps pour les STAPS? Le corps c'est de la biologie, de la psychologie et de la sociologie. Ces trois termes forment un tout qui est le corps.

Highlights Particle size reduction in tumbling mills results from five different mechanisms. Incremental damage is the dominant mechanism for SAG operation. Incremental breakage progeny are indistinguishable from those of single impacts. DEM prediction of abrasive size reduction is qualitatively accurate for AG mills. DEM prediction of incremental damage matches experiment well for SAG operation.

based on semiautogenous (SAG) milling and involve as a rule primary wet autogenous mill (WAM) and a series of ball mills. WAM is customary chosen either based on examination of analogous equipment specifications, or from the evidence of very expensive commercial and semicommercial testing that requires large sampling, much time and high investment

Distinguer Somme, Différence, Produit et Quotient. Les 4 opérations mathématiques principales sont l' addition, la soustraction, la multiplication et la division. Le résultat de ces opérations est respectivement appelé une somme, une difference, un produit et un quotient.

SabodalaMassawa is the largest producing gold mine in Senegal and has been in operation for over a decade. The mine was acquired as part of Endeavour's acquisition of Teranga in February 2021. Endeavour is currently expanding the SabodalaMassawa mine with the addition of a new BIOX processing facility. The new processing facility will add ...

The Huckleberry mine, located in British Columbia, produces roughly 40 million lb/y of copper. A comprehensive energy and cost study compared an existing SAG millbased circuit at the Huckleberry mine with two proposed circuits involving comminution technologies that are associated with energy efficiency: highpressure grinding rolls (HPGR) and highspeed stirred mills.

Working Principle of a SAG Mill. The rock and grinding media are placed in the mill and rotated, causing the grinding media to tumble and crush the rock into smaller pieces. The mill operates in a closed circuit with screens that size the ore and send it back to the mill for further grinding. The product from the mill is then sent to a cyclone ...

SemiAutogenous Mills/ SAG Mills (primary grinding mill) — these mills use grinding balls with forces of attrition, impact, and abrasion between grinding balls and ore particles that result in ...

mill diameter, mill length, grates openings, and pebble ports size; the power equation is also function of all the operational variables selected for this study. The applied force is a function of the mass inside the mill and it is composed of balls, ore and water. The ball charge is a function of the bulk fraction of the SAG mill volume (Jb)

Un broyeur SAG est généralement un broyeur primaire ou de première étape. Les broyeurs SAG utilisent une charge de billes de 8 à 21 %. [6] [7] Le plus grand broyeur SAG mesure 42′ (12,8 m) de diamètre, alimenté par un moteur de 28 MW (38 000 HP). [8] Un broyeur SAG d'un diamètre de 44′ (13,4 m) et d'une puissance de 35 MW (47 000 HP ...

When SAG mill liner bolts loosen, break or stretch beyond limits, liner impairment and degraded performance are generally next on the agenda, followed by mill stoppage for repair or replacement. Bolts and nuts — among the smallest mechanical components used in grinding mills — play a big role in ensuring whether a mill can be efficiently ...

SAG Mill Components. Once the basic operating conditions have been defined for the mill designer then, and only then, can he begin taking into account shell and head stresses and trunnion bearing sizes required to carry the load and to give the required openings for feeding and discharging the mills. Mill heads are key structural components of ...

The literal meaning is: Qu'estce → What is this. Que → That. C'est → This is. : "Estce " = "C'est " but inverted. This French sentence is (sadly) popular for being impossible to explain to beginners because the literal meaning is complete nonsense. This is generally translated as: "What is it? " or "What is that?

> Mill throughput and efficiency gains are iterative over time > Mill trajectory modelling based on bar heights, angles, spacing and speed is very predictive > Field trials are the acid test operator, designer and vendor > Optimisation strategy: Maximise impact grinding AG/SAG mills Avoid impact on the shell rather the toe of the charge

involves replacing the mill charge several times throughout the test. The Bond tests are typically run for a minimum of seven cycles, while the MacPherson and pilot plant tests are operated for about 610 hours. The achievement of steadystate is desirable in a grinding test, because harder components may build up over time. For AG/SAG mills,