AG mills (or SAG mills with low ball charges) are often used in singlestage grinding applications. Based on their higher throughput and coarser grind relative to AG mills, it is more common for SAG mills to he used as the primary stage of grinding, followed by a second stage of milling. AG/SAG circuits producing a fine grind (particularly ...

SAG Mill و Ball Mill

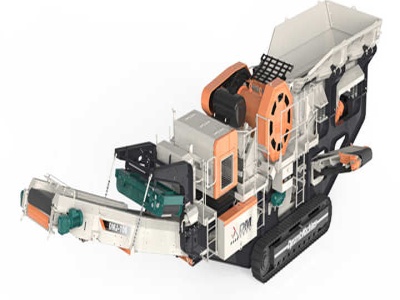

SAG (SemiAutogenous Grinding) mill is a type of grinding equipment widely used in the mining industry. It is a combination of machines used to break down large pieces of rock into smaller pieces of rock, gravel, or even dust. SAG mills are often used in conjunction with ball mills, but they are not the same.

High costeffectiveness CITIC HIC grinding mills are recognized as China's Manufacturing Industry Single Champion Product. CITIC HIC is responsible for setting the national standards of semiautogenous mills (SAG mills) and ball mils, supported by powerful database, optimized process technology, cuttingedge design concept, and 60 years of experience in developing and nurturing innovative ...

Rod mills: Although rarely used in industrial practice, ALS has 2 x kW rod mills for small (<50 kg/h) throughputs where preferential coarse grinding is advantageous for the downstream processing. Ball mills: Ball mills are the stalwart unit of the majority of pilot grinding circuits. ALS has a range of rubber lined overflow ball mills ...

As there are no SAG mills and no ball mills in the HPGRHPGR circuit there are additional savings in CO 2 from the fact that steel ball consumption is zero. A further 15 megatonnes of CO 2 is therefore estimated to be potentially saved, giving a total saving of megatonnes of CO 2 or % compared to a AG/SAGBall mill circuits.

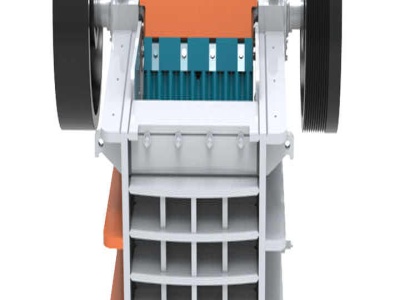

SAG mill vs Ball mill Both sag mill and ball mil are cyclinder type grinding mill. SAG mills usually have a larger diameter than length. While ball mills have a larger length than diameter, so that there can be more grinding time and finished material could be more finer. stage

Then, in the late 1980s when the price of copper rose quickly from a low of /lb to a high of /lb, this substantial increase in price further fuelled the industry demand for larger diameter SAG mills, with mill power quickly doubling from 15,000hp to 30,000hp (11,00022,000kW). As SAG mills grew in size and number, so did the size and ...

Different configurations of SAG, ball and rod mill occur but in general a SAG mill can be considered an intermediate stage in breaking down rock from the crushing plant, and feeding to ball or rod mills for further size reduction. Types of mill Different types of mill are in operation rod or ball mills, so

SAG Mill and Ball Mill Case Study By Ingeteam. In September 2011, the company Outotec, located in Espoo (Finland), awarded Ingeteam a contract for the design and supply of the main drive equipment for a SAG mill and a ball mill to be installed in Russia. Outotec is a global leading company that designs and delivers turnkey projects ...

The three gearless mill drive (GMD) systems are the ABB most powerful ever made. The GMD for the 40foot SAG mill has a power rating of 28 megawatts (MW), and the GMDs for the two 28foot ball mills have a power rating of 22 MW. They are the largest diameter and most powerful SAG and ball mills drive systems at the highest altitude installed to ...

Ball Mill AG/SAG Mill min max min max DESIGN DATA diameter inside shell (m) belly length inside liners (m) liner thickness (mm) 51 152 51 152 diameter inside shell (ft) 3 26 6 40 belly length inside liners (ft) 5 40 liner thickness (inch) 2 6 2 6

In fact, in four of the surveys, the SAG mill was found to be more efficient at producing circuit product than the ball mill. Similar results have been seen consistently across all the surveys where this approach has been used, including circuits with AG mills, pebble mills, HPGR, stirred mills and ball mills with fine screens. Figure 2 ...

Figure 1 Ball mill shells delivered and brought into the mill building. Figure 2 Ball mill cradle being installed. Figure 3 Ball mill shell being lowered into the cradle. Figure 4 SAG mill shell ...

If a ball mill uses little or no water during grinding, it is a 'dry' mill. If a ball mill uses water during grinding, it is a 'wet' mill. A typical ball mill will have a drum length that is 1 or times the drum diameter. Ball mills with a drum length to diameter ratio greater than are referred to as tube mills.

Working: SAG mill make use of steel balls included with some large and hard rocks for grinding. These mills utilize the balls in making the large fragments of materials broken into pieces. The ball charge of a SAG mill is about 9% to 20%.This process takes place inside the large rotating drum of SAG mill which is filled with balls partially.

When future tonnage needs to be increased, the SAG Mill can feed downstream ball mills to boost capacity. When it comes to the biggest of the big, FLSmidth has experienced a great deal of success with SAG and ball mills. "We just sold our 27 th 40ftdia. SAG mill," said Anthony Filidore, head of GPLMMining Comminution for FLSmidth. "Of ...

The present study investigates the propensity of predicting ore grindability characteristics and varying pulp densities through acoustic measurements on the Magotteaux ball mill. Specifically, the grinding behaviour of two different mill feeds (model quartz and iron ore) together with solid loadings (50, 57, and 67 wt% solids) were correlated ...

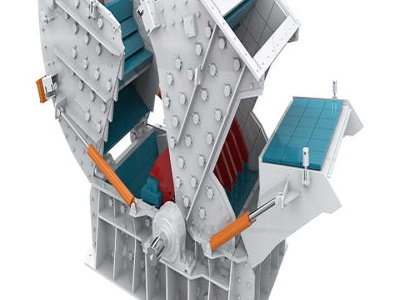

Semiautogenous grinding mills (SAG mills) are tumbling mills that most commonly have a shell diametertolength ratio of around two. With this high aspect ratio, SAG mills generate both thrown and cascading ballmilling actions with shell linings shaped to lift and to throw alloy steel grinding balls of up to 150 mm (6 in.) in diameter. These

30 mm. Installed grinding power is split equally between the two mills with the SAG mill fitted with a variable speed drive (VSD). SAG discharge screen oversize ('pebbles' or 'scats') was recycled through an 185 kW pebble crusher. The circuit was characterised by a high circulating load around the ball mill, with a

WiBM Bond Ball Mill Test Work Index (kWh/t) 3. KEYWORDS Autogenous Grinding (AG), Ball mill, Bond Work Index (Wi), Comminution circuit, High Pressure Grinding Rolls (HPGRs), Rod mill, SemiAutogenous Grinding (SAG), Specific energy (W) 4. INTRODUCTION AND BACKGROUND The Morrell method for predicting the specific energy

Ball Mills. The ball mill accepts the SAG or AG mill product. Ball mills give a controlled final grind and produce flotation feed of a uniform size. Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is ...

... Recently, Jahani Chegeni and Kolahi [23] have investigated the effect of seven different types of liners on the performance of industrial scale SAG mills by DEM. They concluded that the...

SAG mill VS Ball Rod Mill (2 replies and 2 comments) N Nikita Gupta 4 years ago I would like to understand why do companies use SAG mills instead of Rod mills for grinding these days? Apart from the alleviation of need for secondary and tertiary crushers, is there any other reason for inclination towards the installation of SAG mills. SmartDog

The SAG mill feeds two FLSmidth ball mills each 26 ft. in diameter × 40 ft. long (EGL), each driven by a 16,400 kW drive. The SAG mill is one of the largest volumetric capacity SAG mills in the world and represented the first 40 ft. SAG mill in Peru (Garcia Villanueva, 2013 [1]). Antapaccay's flow sheet is shown in Figure 1 below.

A large 24foot ( m) diameter ball mill charge typically weighs around 2 million lbs (907 tons). Semi Autogenous Grinding (SAG) mill charge can be equally as heavy. The charge starts tumbling at different angles, depending on the application and size of the mill.

Most SAG mill are not optimized for the combined SAG Ball mill throughput such as: SAG Ball mill % ball content SAG % ore content SAG grate size and end mill design including grate geometry, location, shape, pan cavity, recycle % in pan cavity, et. al. SAG lifter and end cone geometry can change SAG mill performance more than 20%50% ...