Mechanical milling is a promising route for production of submicron and nano sized silicon powders, but it is challenging to predict and control the product properties. In this study a metallurgical grade silicon quality was milled in a planetary ball mill and the properties of the powder were investigated as a function of grinding time, grinding bead size (20 mm, 2 mm, mm) and rotational ...

Fe Nanopowders Ball Milling

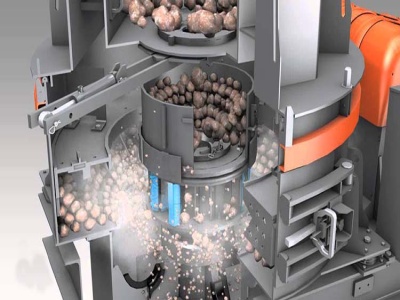

Ball milling experiments were done in a high energy planetary ball mill at a rotating speed of 300 rpm. To avoid the occurrence of any undesirable polluted phases, the ballmilling experiments were halted periodically (every ks) and then restarted when the temperature of the vial reached about 300 K.

The starting material used was TiC powders (% purity) with an average particle size of 10 μ TiC particles exhibited an irregular shape and faceted surface morphology, as presented in Fig. raw TiC powders were ballmilled as functions of milling time and ball size using a planetary ball mill machine specially designed to carry out the mechanical milling at a very high disk ...

Therefore, FeZVAl bm was synthesized by directly onepot ball milling solid ZVAl, FeSO 4 ·7H 2 O and Fe 3 O 4 to promote the electron release and regulate the electron transfer. FeSO 4 ·7H 2 O and Fe 3 O 4 showed splendid synergy for effectively removing % of PNP unaffected by coexisting ions in a broad pH range (311).

5, 10 and 15 wt% and were added to Fe powders having an using a Retsch PM400 high energy ball mill. The ball to powder ratio was taken as 10:1 and the milling speed was kept at 200 rpm. The balls and vials used were of tungsten carbide. Toluene was used as a process controlling agent. The

Elemental powders of Co, Ni, Fe, Al, Ti and Cr with high purity (> wt%) and particle size of about 30 μm were used as starting materials for processing CoNiFeAl Ti Cr HEA powders. The HEA powders were synthesized by mechanical alloying for 60 h using a highenergy planetary ball mill (QM3SP4 Planetary Ball Mill) at a speed of 300 rpm with tungsten carbide balls and stainless ...

Ball milling is a simple, fast, costeffective green technology with enormous potential. One of the most interesting applications of this technology in the field of cellulose is the preparation and the chemical modification of cellulose nanocrystals and nanofibers. Although a number of studies have been repo Recent Review Articles Nanoscale Advances Most Popular Articles

Large value of α may lead to high dimensional stability of material, hence the α can be used to determine the ball milling ball milling process of 250−300 rpm ball milling speeds and 5−7 h ball milling times are recommended based on α, which causes a 95100 % increase in σ yc and a 3035 % decrease in CTE compared ...

In the present work, FeMnAlC powder mixtures were manufactured by elemental powders with different ball milling time, and the porous highMn and highAl steel was fabricated by powder sintering. The results indicated that the powder size significantly decreased, and the morphology of the Fe powder tended to be increasingly flat as the milling time increased. However, the prolonged milling ...

The ballmilling conditions in the ball mill are mainly related to the setting of the parameters of the ball milling, primarily the ball milling atmosphere. In general, the ball mill is commonly vacuumed or filled with an inert gas (argon or helium) during the milling process. Besides, the ball mill tank as a whole is a closed system.

Ce14Fe78Co2B6 nanopowders with hardmagnetic properties have been successfully prepared by ball milling at low temperatures in liquid nitrogen. The morphology, structure, and magnetic...

Ball milling experiments were done in a high energy planetary ball mill at a rotating speed of 300 rpm. To avoid the occurrence of any undesirable polluted phases, the ballmilling experiments were halted periodically (every ks) and then restarted when the temperature of the vial reached about 300 K.

Fe10Cr5Y2O3 powders were mechanically alloyed using a high energy horizontal ballmill apparatus, and the effect of heat treatment on the behavior of nanosized oxide particles formed in the ...

Snbased alloys have emerged as highcapacity, lowworking voltage anodes for sodiumion batteries (SIBs) in recent years, but the complex synthesis processes for the highly reversible anodes have impeded their practical application. Herein, DFT calculations demonstrated that SnS2 and Fe can undergo a series

It is a ball milling process where a powder mixture placed in the ball mill is subjected to highenergy collision from the balls. This process was developed by Benjamin and his coworkers at the International Nickel Company in the late of 1960. ... The 85 mol% aFe 2 O 3 SnO 2 sample milled for 110 hours showed the highest sensitivity among ...

Ballmilling Post annealing Magnetic properties 1. Introduction The irontitanium oxides are widely found throughout nature and has been field of numerous explorations in the past decades [1], [2], [3], [4].

After further ball milling for up to 16 h and 24 h, the thickness of GNPs, introduced at the network boundaries, became thin, implying the reduction of the layers. However, it seemed to create an optical illusion, which the thickness of graphene was increased as shown in Fig. 6 e and f. The misleading phenomenon could be attributed to the ...

The structural changes in the Fe 80 Nb 10 B 10 metallic glass subjected to ball milling have been studied using DSC, Xray diffraction and VSM. Deformationinduced αFe nanocrystals are observed after milling the samples for 20 h. Upon further milling to 40 and 60 h the amount of crystals increases.

In this work, we propose the synthesis of ZnO nanostructures through the thermal oxidation of ballmilled powders with the introduction of Mg and Sn doping species at the preliminary step of milling. We investigate the advantages and challenges of this two steps process for the production and fabrication of highly crystalline ZnO nanowires. This simple method allows us to fabricate ZnO ...

The structural phase transitions of the ballmilled AlCuFe nanopowders during constant rate heating were investigated by in situ Xray diffraction at the B2 beamline at desyhasylab (Hamburg, Germany). High ... powders with nominal composition Al 67 Cu 23 Fe 10 were prepared by mechanical alloying using a highenergy planetary ballmill ...

High energy ball milling (HEBM) of ferrimagnetic γFe 2 O 3 nanoparticles results in enhanced capacitive properties. The effect of HEBM on particle morphology is analyzed. Gallocyanine is used as a codispersant for γFe 2 O 3 and MWCNTs.

wt% Y 2 O 3 powders were mechanically alloyed (MA) in a RETSCHPM 100 planetary mill at a rotation rate of 400 rpm for various milling times (, 1,, 2, and 10 h). Besides, pure AA7075 (unmilled) was utilized as a reference sample for comparison purposes. The 10 mm diameter tungsten carbide (WC) balls in a tungsten carbide jar were used, and the balltopowder (BPR) mass ...

In this investigation, the chemical and structural characteristics of Fe nanoparticles synthesized by highenergy ball milling have been explored. After the milling process the nanoparticles were collected using a magnetic field. The structure, morphology and composition of the powders were obtained using highresolution electron microscopy. HREM images confirmed the nanoparticles' presence ...

This research is focus on synthesis of ZnO nanoparticles (ZnONPs) for biological application by Ballmilling process. This research presents the synthesis of ZnO nanoparticles with the difference calcined temperatures ranging from 400 to 900 °C effect on size and morphology. The synthesis ZnO nanoparticles were characterized by employing ...

In the present work, a MgLaFeH nanocomposite was prepared through reactive ball milling of the mixture of MgH 2, Fe and La powders. The phase components, microstructure and hydrogen sorption properties of the composite powders were carefully investigated. After milling, an unsaturated hydride LaH formed in the

Abstract We investigate the structural and magnetic properties of Fe2 TiO 5 nanopowders prepared by ballmilling and post annealing. From the structural analysis, we observe the crystalline signature of the pseudobrookite phase.

The XRD data of the powder at different stages of the synthesis route has been shown in Fig. starting powder is in the αFe BCC phase. After ball milling, the powder is still in the BCC Fe phase, but a certain orientation was observed at the peak of 200 due to texture formed by plastic deformation (and the subsequently stimulated strain) induced during the ball milling procedure.