MenéndezAguado et al. examined the possibility of determining the work index in a Denver laboratory batch ball mill with the same inner diameter as the Bond ball standard mill. The research was performed on the size class of 100% − mm using samples of gypsum, celestite, feldspar, clinker, limestone, fluorite, and copper slag.

Ball Mill Experience Lab Report PDF

Type of ball mill: • There is no fundamental restriction to the type of ball mill used for organic synthesis (planetary ball mill, mixer ball mill, vibration ball mill, .). • The scale of reaction determines the size and the type of ball mill. • Vessels for laboratory vibration ball mills are normally restricted to a volume of 50 cm3.

The period, T T, of a pendulum of length L L undergoing simple harmonic motion is given by: T = 2π L g−−√ T = 2 π L g. Thus, by measuring the period of a pendulum as well as its length, we can determine the value of g g: g = 4π2L T2 g = 4 π 2 L T 2. We assumed that the frequency and period of the pendulum depend on the length of the ...

1. 300500g of coarse sugar was weighed. 2. The various sizes of metal balls were put into the mill. 3. The coarse sugar was added into the mill. 4. The milling process was started for 1520 minutes with the appropriate speed. 5. The product was weighed again.

Objectives: 1. To grind the given material to a smaller size using a ball mill and to. obtain the size distribution of the initial and final mixture by sieving. f2. To estimate the energy required for the grinding operation. 3. To analyze the results using available theories.

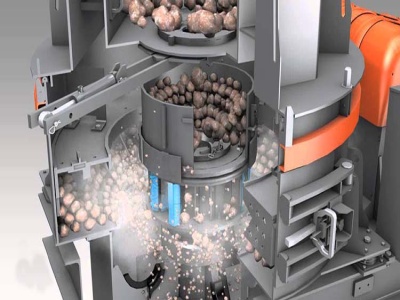

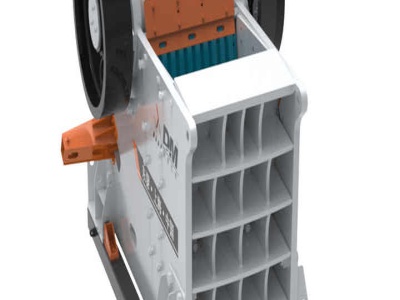

A ball mill is a type of grinder used to grind and blend materials for use in mineral. dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. It. works on the principle of impact and attrition: size reduction is done by impact as the. balls drop from near the top of the shell.

The aim of this experiment was to screen and sieve haematite ore and to study its particle size distribution. The screening was done using an industrial screen and the sieving was done using laboratory Tyler sieves. The initial mass of the ore manually fed to the screen was kg.

Ballmilling Jackie

4. Later, take the sample that have been split and placed in a measuring cylinder up to 700ml packed. The weight of the measuring cylinder with the sample were measured. 5. The sample then was placed in the ball mill to be grind. The starting revolution use was 150rpm. 6. After that, the mill was emptied and the ball mill charge was screened out.

View Lab ball from CMT 450 at Universiti Teknologi Mara. CMT 450 LABORATORY REPORT Experiment 4 Title: Size Reduction Using Ball Mill and Screen Analysis Using Sieve Shaker Name: MOHAMMAD. ... Your News 2. A vrrp vrid 1 track bfd session session name 1 reduced 100 B bfd sesssion vrrp.

The ball mill is the key equipment for grinding the minerals after the ore is crushed. With the continuous development of the industrial level, the development of ball mills is also moving towards ...

of ball load composition, by varying the grinding media size distribution ( alternatively by mixing four groups of, 38 mm;, 50 mm; 38, 50 mm and, 38, 50 mm), on the milling efficiency of a laboratory scale ball mill has been investigated in this article concerning ball number, total surface area, and ball weight.

First, laboratory ball mills are much smaller in size than industrial ball mills, and they are designed to fit on a laboratory bench or table. Second, laboratory ball mills are typically used for smaller batch sizes, whereas industrial ball mills are designed for largescale production. Third, laboratory ball mills are usually operated with ...

The common laboratory highstress abrasion apparatuses suffer from lack of capability of closely simulating the service conditions of grinding media and mill liners, being the main consumables in these sectors. The ball mill abrasion test (BMAT) is a versatile abrasive wear tester that facilitates reliable modelling of kinematics and contact ...

A comprehensive investigation was conducted to delineate the effect of ball size distribution, mill speed, and their interactions on power draw, charge motion, and balls segregation in a laboratoryscale mill. The mill was simulated at different critical speeds with different mill fillings. In total, 165 scenarios were simulated.

Ball mill. Aim: To determine the (a) Critical speed (b) Actual speed (c) Optimum speed (d) Reduction ratio (e) Constants for (i) Rittinger's Law (ii) Kick's Law (iii) Bond's Law. Equipment and Materials required: Ball mill, sieves, weight balance,Coal Theory: The ball mill is used for fine grinding of soft materials. Here, the size reduction is done by the impact of ball which is generally 1 ...

We carried out a detailed study on the effect of particle load and ball load on grinding kinetics. by carrying out experiments at two different mill speeds (55 and 70 % critical) and four levels ...

The instant when the ball is released is considered to be the initial time t = 0. The position of the ball along the ruler is described by the variable y. The position of the ball at a time t is given by y(t) = y 0 + v 0t+ 1 2 gt2: (1) If the ball is released from rest, the initial velocity is zero: v 0 = 0. Therefore, y(t) = y 0 + 1 2 gt2: (2) 1

Abstract and Figures. In this paper a new digital energy meter is being evaluated as a means of measuring the energy required to grind ore in the Bond mill and to test if the results are ...

The ball mill maintenance period can be divided into 36 months for minor repair, 612 months for medium repair and 60120 months for major repair. In the daily operation process, we should also pay attention to the ball mill maintenance. These are the basic maintenance conditions

The vertical mill demonstrated the same ability to achieve the product specifications of the ball mills while proved to be able to reduce the medium specific energy consumption in about 40%. Read more

This study which aimed for investigation of ball shapes effect to grinding performance has two different experimental media. First experiment achieved by traditional spherical balls where the ...

The ultimate crystalline size of graphite, estimated by the Raman intensity ratio, of nm for the agate ballmill is smaller than that of nm for the stainless ballmill, while the milling ...

A laboratory ball mill is an indispensable tool when it comes to the rapid, reproducible pulverizing, milling or grinding of a large variety of materials. Depending on the configuration and choice of mill, samples can be soft, elastic or fibrous but also hard or brittle. RETSCH offers 11 different laboratory ball mill models (the largest ...

Milling experiments are performed using lactose non pareils in a laboratory scale Hammer Mill. The size and shape of the resultant progeny of particles are analyzed by sieves/light scattering and ...

Introduction: 'Ball milling is a method used to break down the solids to smaller sizes or into a powder. A ball mill is a type of grinder which consists of a cylinder. It is used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. The cylinder rotates around a horizontal axis.