I summarizes the typical thicknesses and rolling speeds for each mill type. Not surprisingly, as the material gets thinner, the speeds increase dramatically. Hot Roughing Mill Hot Finish Mill Cold Rolling Mill Maximum Thickness > 400 mm 2050 mm 320 mm Minimum Thickness 2050 mm 320 mm mm Rolling speeds (meters per min) ~ 100 ~ 1000 ~ 2000

CCM إلى Rolling Mill Direct

Hot Rolling Mill CCM from Luo Yang Hongteng Electrical Equipment Co., Ltd.. Search High Quality Hot Rolling Mill CCM Manufacturing and Exporting supplier on ... Induction Heating Furnace/Billet Heating Furnace/Induction Melting Furnace/Electric Furnace/Ingots Casting Machine/Rolling Mill/Continuous Casting Machine. Ranked #2 ...

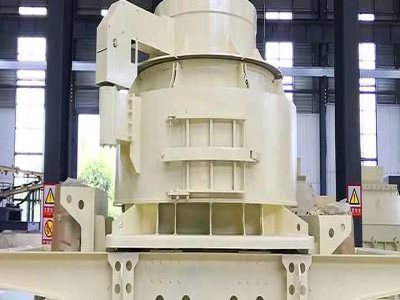

This CCM (Continuous Casting Machine) equipment is used to casting billet main products are, R3M, R4M, R6M, R9M, and R12M continuous casting machine with matching radius. It is composed of large steel ladle, middle steel ladle, crystallizer, vibration device, arc section, primary water cooling, secondary water cooling, dummy bar, billet pulling device, multipoint ...

High casting speeds in the range of 2 m/min to 4 m/min and width of 800 mm to 1600 mm is possible. The caster is connected to rolling mill via a roller hearth reheating furnace which equalizes the slab temperature to 1120 deg C. The rolling mill can include four, five, or six finishing stands depending on product mix and required finishing gauge.

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright ...

The process of rolling affects the materials at a metallurgical level and the desired material thickness can be achieved while also producing the desired tensile strength. Rolling mills can be designed with specialty tooling to impart patterns on the material this is known as an embossed mill. Additionally, grooved mills can be used to ...

In order to achieve smooth operation, the following facilities are required to be installed in the CCM section of any Induction Furnace and rolling mill complex: A suitable radius of the...

Direct rolling of the steel may be termed as converting the billet in to a rolled product without any intermediate reheating arrangement, thereby avoiding wastage of sensible heat of steel. In...

Aluminum rolling mill from LUOYANG JUDIAN METAL HOT PROCESSING EQUIPMENT CO., LTD.. Search High Quality Aluminum rolling mill Manufacturing and Exporting supplier on

Experimental set up. A Hille100 rolling mill with rolls of 225 mm diameter and 254 mm length, driven by a variable speed DC motor of 75 horse power, was used. The maximum rolling force, torque and speed are 1500kN, 13kNm and 70 rpm respectively. The sensor roll nitrided surface hardness is 65 to 70 HRC. The diameter of the top and bottom ...

The continuous casting slab is directly sent to the rolling mill through the corner heating device during the conveying process without passing through the heating furnace under the conditions above A3 temperature. Continuous casting slab hot direct rolling, referred to as CCHDR, is classified into 3 categories.

China supplier of CCM, cold roll mill, cold rolling mill. As one of the most experienced Chinese suppliers of equipment and components for steel and nonferrous industries, SunGlare Ltd. China is engaged in the design, manufacture, engineering and service activities on a worldwide basis.

My Role is Civil Construction Manager. 1 supervising and leading subcontractor team in all civil work. 2 Coordinating with mechanical, Piping, Electrical departments. 3 Review all civil work and handover to Quality control members. 4 review work rate and activities to achieve the schedule dates. 5 review and check subcontractor invoices.

From Shanghai Orient Metallurgical Equipment LtdDetail: Mill / Wire Rod Lines / Rebar Lines / Section Mill Lines / Strip Mill Lines...

The direct rolling process of continuous casting slab refers to that the hightemperature slab from the caster is directly sent to the rolling mill for rolling without heating or only slight supplementary heating of the edges. 5. Advantages of continuous casting and rolling . 1) simplified production process and short production cycle;

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Press Copyright Contact us Creators Advertise Developers Terms Privacy

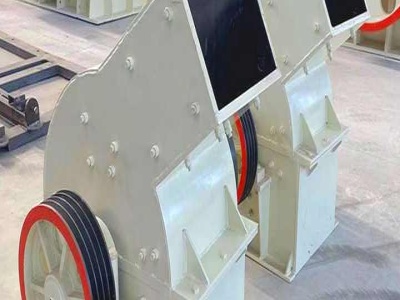

Hot Billet Shear, automatic PLC cutting, inline with the CCM, for direct rolling

The reversing cold rolling mill is the allrounder among the cold rolling mills: Here, thin strips, thick strips, soft grades, highstrength and ultrahighstrength strips can be rolled in succession on one and the same plant. The RCM is mainly used for low carbon steels, but is also a good solution for modern grades such as silicon steels.

Hot rolling and hot extruding drawing involves working above the recrystallization point of the steel. The mill passes the heated material through a variable...

Cold rolling reduction is an important factor that affects drawability of IF steel. It has been observed that increasing cold rolling reduction increases the r m value, at least up to 90% [34].This effect has been shown in Fig. the most important parameters in the production of a strong {111} recrystallization texture are the annealing temperature and the time of holding [35].

Hot Rolling Mill CCM from Luo Yang Hongteng Electrical Equipment Co., Ltd.. Search High Quality Hot Rolling Mill CCM Manufacturing and Exporting supplier on

4. Reducing production costs is an effective way for enterprises to increase efficiency; 5. Conducive to the application of endless rolling technology. The disadvantages are: due to the high hardness and brittleness of cemented carbide roll ring and high sensitivity to cracks, it is difficult to maintain, and the requirement for cooling water ...

Cross Transfer for CCM ... التخطي إلى المحتوى الرئيسي LinkedIn. المقالات الأشخاص التعلم الوظائف انضم الآن تسجيل الدخول منشور BLS Rolling Mill Meltshop Technologies BLS Rolling Mill Meltshop Technologies ١٬٢٧٧ متابع ...

عرض ملف aiham الشخصي الكامل. Seeking a position as an industrial automation engineer where I can utilize my experience in an automation specialist role that demands creativity, motivation, and development with direct contribution to the growth of the organization. Experience that includes Siemens PLC and SCADA systems, Danieli ...

Site Challenges in Hot Rolling Mill. The temperature of hot rolling is around 1000°C to 1300°C. The hot rolling mill having a challenging environment for making any kind of temperature measurements like high temperature and the movement of the metal, make thermocouples and other contact temperature sensors impractical.

History of Hot Strip Mills1. John G. Lenard, in Primer on Flat Rolling (Second Edition), 2014 Generation III Coil Box Hot Strip Mills. In the 1970s, Stelco of Canada developed the hot coil box designed for installation in hot strip mills ahead of the finish mill for coiling the transfer bar from the roughing mill and uncoiling it into the finishing mill.

The HewlettPackard 620640 Page Mill Road (HP) Superfund site is in Palo Alto, California. HP made optoelectronic equipment at the 10acre area from 1962 to 1986. ... In the late 1990s, the PRPs fenced the site to prevent direct contact with contamination. Construction of a slurry wall and extraction well system finished in 1999. The system is ...