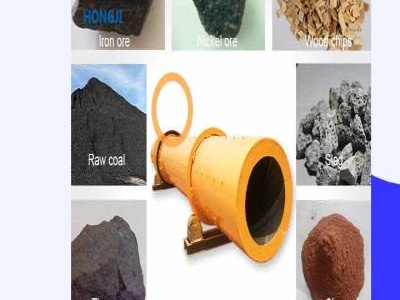

The ball mill is used for the grinding of a wide range of materials, including. coal, pigments, and felspar for pottery, and will take feed up to about 50 mm. in size. The efficiency of grinding increases with the holdup in the mill, until. the voids between the balls are filled. Further increase in the quantity then.

عمل Ball Mill PDF

Ball mill is a kind of raw material processing machinery which plays the role of grinding. Its working principle is that the movement and force are transmitted to the barrel of ball mill...

The Cadia deposit is a mills of unproven design {40 ft x 20 ft ( m x m) large, homogeneous, low grade, porphyrytype gold SAG mill and 22 ft x ft ( m x m) ball mills}. copper resource.

A pebble Mill is any Mill in which flint pebbles or porcelain balls are used as the grinding media, and the inside of the cylinder is lined with either porcelain, burrstone, rubber, or some other nonmetallic lines. Steel Ball Mills grind faster due to the use of steel balls, which weigh more than three times as much as a porcelain ball.

its application for energy consumption of ball mills in ceramic industry based on power feature deployment, Advances in Applied Ceramics, DOI: /

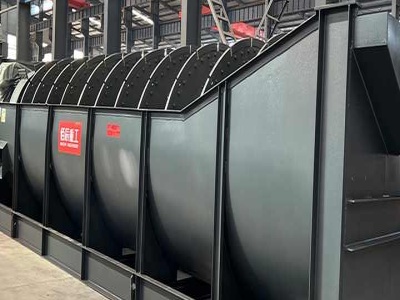

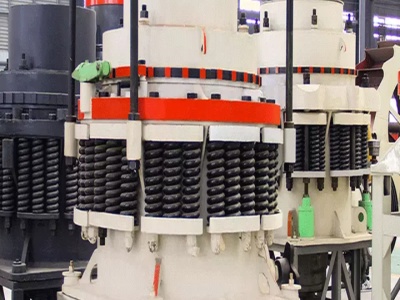

ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 50% of the mill volume and its size depends on the feed and mill size.

This method allows production of homogeneous materials starting from blended elemental powder mixtures produce a nickelbased superalloy. Mechanical alloying (MA) is a solidstate powder processing technique that involves repeated cold welding, fracturing, and rewelding of powder particles in a highenergy ball mill.

However, the maximum in power occurs at different fractions of critical speed from one mill to another, depending on the mill diameter, the type of lifters, the ratio of ball to mill diameter, and the ball and powder filling conditions. The maximum is usually found in the range of 70 to 85%' of critical speed. Within the range of speed near the ...

Module 7 Ballmilling Ball milling is an economic and facile technique to produce nanosized materials. It is a topdown approach of nanoparticle synthesis which includes mechanical breakdown of large substances into smaller one. It is used in producing metallic as well as ceramic nanomaterials.

In ball mill, ball has to be charged around 3032% in first and second compartments. Balls are in the range of 5090mm in coarse and 1550mm in fine grinding. Grinding of material takes place by means of collision or attrition or tumbling action takes place between the balls and the charge. ...

If a ball mill uses little or no water during grinding, it is a 'dry' mill. If a ball mill uses water during grinding, it is a 'wet' mill. A typical ball mill will have a drum length that is 1 or times the drum diameter. Ball mills with a drum length to diameter ratio greater than are referred to as tube mills.

Mechanical milling is a promising route for production of submicron and nano sized silicon powders, but it is challenging to predict and control the product properties. In this study a metallurgical grade silicon quality was milled in a planetary ball mill and the properties of the powder were investigated as a function of grinding time, grinding bead size (20 mm, 2 mm, mm) and rotational ...

The purpose of this manual is to assist you in the proper installation and to acquaint you a bit further with the assembly and care of this equipment. We suggest that these instructions be read carefully and reviewed by everyone whenever involved in the actual installation and operation of the mill.

involve grinding). With Lloyd's ball milling book having sold over 2000 copies, there are probably over 1000 home built ball mills operating in just America alone. This article borrows from Lloyd's research, which was obtained from the commercial ball milling industry, and explains some of the key design criteria for making your own ball mill.

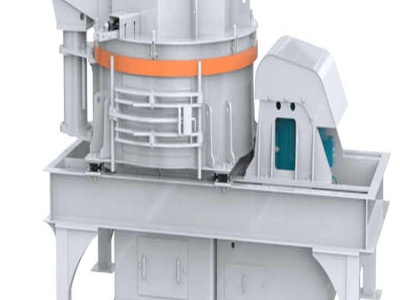

Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually times the shell diameter (Figure ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 2040% water by weight.

to ball filling variation in the mill. The results obtained from this work show, the ball filling percentage variation is between % which is lower than mill ball filling percentage, according to the designed conditions (15%). In addition, acquired load samplings result for mill ball filling was %.

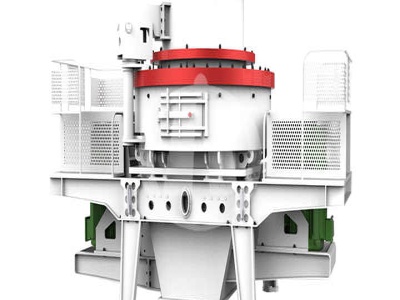

Introduction Ball Mill Ball mill is the key equipment for grinding materials after crushing and screening. It is also commonly used in grinding equipment. Dry Ball Mill: I. It is mainly used in refractory, fertilizer, cement and glass industries; II.

Ball Mills. 【 Capacity 】 T/H. 【 Max Feeding Size 】 <25mm. 【 Discharge Size 】 【 Types 】Overflow ball mills, grate discharge ball mills. 【Advantages】 Designed for long service life and minimum maintenance, can grind and homogenize mineral ores down to the nano range, with a large processing capacity.

Based on his work, this formula can be derived for ball diameter sizing and selection: Dm <= 6 (log dk) * d^ where D m = the diameter of the singlesized balls in = the diameter of the largest chunks of ore in the mill feed in mm. dk = the P90 or fineness of the finished product in microns (um)with this the finished product is ...

A wet grinding ball mill in closed circuit is to be detective 100 TPH of a substance with a work index of 15 and a size distributor of 80% passing ¼ inch (6350 microns). The required product size market is to breathe 80% passing 100 mesh (149 microns). In order in define the influence requirement, the steps are as follows:

View. Show abstract. ... The most advanced approach to simulate ball mills emerged in the early 1990s, by combining information from the mechanical environment in ball mills, obtained using the ...

Mechanochemical technique aims to strike a balance between defect formation via ball milling and size adjustment of a solid grain to nanoscale (<1000 nm) (Ullah et al., 2014).During the process, a highenergy mill is employed and a specific powder charge is placed along with a milling medium (Lin et al., 2017).The kinetic energy generated during the motion of moving balls is applied to the ...

A mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand or by animals (, via a hand crank), working ...

Ball mill is an operating unit used to grind various types of solid materials into finer particle sizes. The purpose of this study was to determine the best variation of operating conditions of ...

Over the years, alternative procedures to the Bond grindability test have been proposed aiming to avoid the need for the standard mill or to reduce and simplify the grinding procedure. Some of them use the standard mill, while others are based on a nonstandard mill or computation techniques. Therefore, papers targeting to propose a better alternative claim to improve validity, to reduce test ...

The ball mill maintenance period can be divided into 36 months for minor repair, 612 months for medium repair and 60120 months for major repair. In the daily operation process, we should also pay attention to the ball mill maintenance. These are the basic maintenance conditions

In this case the grinding circuit comprises an open circuit rod mill followed by a closedcircuit ball mill. The ball mill is most often closed over a classifier like a hydro cyclone (Fig. ) or DSM style screen with a fine cut of mm. The course material is returned to the ball mill feed and the fine screen underflow reports to the ...

Ball Milling DESIGN AND FABRICATION OF MINI BALL MILL Affiliation: F aculty of Mechanical Engineering, Universiti Malaysia Pahang (UMP), 26600 Pekan, Pahang, Malaysia Authors: Wei Xian Hong...

The sample was received crushed appropriately for the ball mill test. Ball Mill Grindability Test was conducted by standard practice using 100mesh (150 pm) closing screens. The ball mill work index is shown below. BM Wi (kWhr/st) = ; BM Wi (kWhr/mt) = ; Bond Ball Mill

1 Arm of gravity * ( 1 4 * R2 ) Torque factor matrix TAN [ / R * (1 4*R ) ] [ 2*R * (1 4*R ) 1 2 Deff Centre Distance (from mill centre to media top layer), mts Deff Mill effective diameter, mts h/Deff, ratio of centre distance to mill effective diameter Target u

V — Effective volume of ball mill, m3; G2 — Material less than in product accounts for the percentage of total material, %; G1 — Material less than in ore feeding accounts for in the percentage of the total material, %; q'm — Unit productivity calculated according to the new generation grade (), t/(). The values of q'm are determined by ...

FOTE BALL MILL 16 fThe maintains and examine repair of ball mill 1 All the lubes should change once a month, and in the future, according to the repair and examine change the lube once per six month. 2 Every lubricant part and the surface height of the oil should be examined once per four hours. 3 When the mill works normally, the temperature ...

For mechanochemical synthesis inside a highspeed ball mill, the nature of the milling material is a crucial variable along with the type of the ball mill itself. 95 The density of the milling material is directly related to its moment of inertia, and therefore, the kinetic energy transferred to the sample. 22 The most frequently utilised ...