In total 76 data sets were generated covering the power draws of ball, SAG and AG mills in the range 7 7900 kW. All three models were found to predict the power draw of the mills in the data ...

تكلفة KW Ball Mill

Question: a ball mill is operating at an efficiency of 95% with a filling volume of maximum 3. the ore has a Wi od 20 kW/ton. The RD of the crushing balls are The charge volume is about 55% calculate what length and diameter of mill is (a) required to reduce ore size from 6mm to 200(um) (b) what will be the critical speed of the mill assuming or specific

The ball mill is a m by gold and support dissolution into pregnant secondary haulage, road maintenance, mill m low aspect rubber lined mill fitted with eluate. crusher feed and waste rock management a 2,200 kW motor the ball mill operates in The wet circuit comprises a CIL circuit with operations. closed circuit.

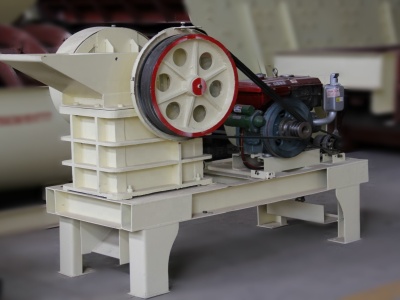

machines such as; ball and SAG mills, crushers, conveyors, compressors, chippers, fans, pumps, mixers and saws Key benefits • Simple,easytounderstand technology ... starter model nominal motor kW rating at starting torque of; single motor drives x flT x flT x flT x flT m350/2 500 355 250 185 m350/3 750 650 450 315.

This PDF document contains the FY23 NAVSEA Standard Items, which are the technical requirements for ship maintenance and repair. The document covers various topics such as deck covering, welding, painting, and more. The document is updated as of 01 October 2021 and is applicable to all contracts awarded on or after that date.

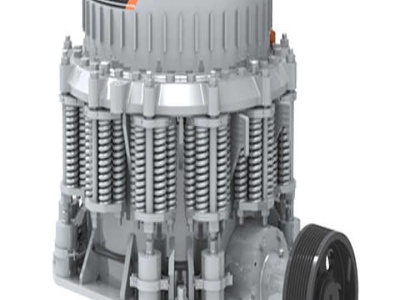

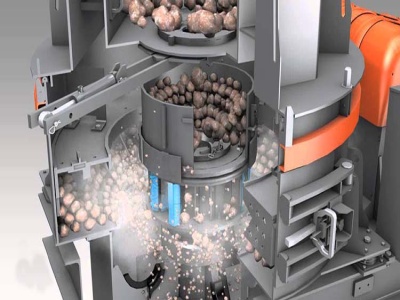

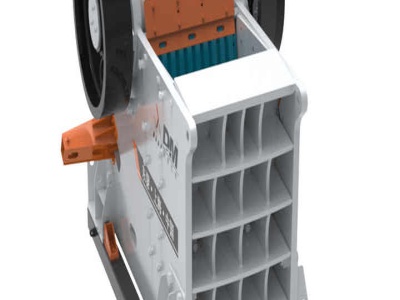

A mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand or by animals (, via a hand crank), working ...

Question: 150 ton/day of pyrite of 2 mm average size need to be milled to an average size of mm, using any of three ball mills of, 25, and 50 cm in diameter, respectively, all with balls of 5 cm of diameter as the pulverizing medium. Which mill would be more adequate to perform the duty knowing that, everything included, 10 kW/rpm are approximately needed to

I totally agree with you that the low charge rate directly affects the grinding efficiency, but in here there is another thing we have, that shouldn't be overlooked, it is the power consumption, at low charge rates below 20% the power consumption increase by 615% for the ball mills. (unknown) 8 years ago Like

Predictive Controller Design for a Cement Ball Mill Grinding Process under Larger Heterogeneities in Clinker Using StateSpace Models September 2020 DOI: /designs

A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns). The required product size distribution is to be 80% passing 100 mesh (149 microns). In order to determine the power requirement, the steps are as follows: Example Calculation

The standard Bond Mill test applies for coarser ball milling, but is not appropriate for stirred milling with fine media grinding to 70 microns. With no industry standard test, the ... reported from the kW lab mill to the full scale 355 kW mill that is the full scale mill was less efficient than predicted from testwork. This may be ...

An inefficient ball mill is a major expense and could even cost you product quality. The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance. With more than 4000 references worldwide, the FLSmidth ball mill is proven to do just that.

4 Ball mill for cement grinding Ball mill for cement grinding 5 Outlet grate with adjustable lifters Slide shoe bearing Mill shell with weldedin slide rings and ... Power (kW) x 13 2570 x 3130 x 3660 x 4205 x 4535

Svedala / Metso model VTM800WB. Vertimill vertical ball mill. Screw speed: RPM. Rotation direction: clockwise (viewed from top) Grinding media type: steel grinding balls. Motor and Drive. 600 KW Motor. 1000 RPM. Flender planetary gear reducer.

Morrell (1996) published a large database of ball, ag and sag mills. This data base has been extended considerably since then and includes data from ball mills up to 26ft in diameter drawing over 10 MW as well as sag mills up to 40 ft in diameter drawing 18 MW. Ball mill data sets number 59 and a histogram of the diameters of these mills is ...

a 1000 kW ball mil l at the Boddington Supergene Plant. At that stage, ... Using an overall electrical energy saving of 15% for the HPGRBall mill circuit compared to the AG/SAGBall Mill circuit ...

A SIMPLE METHOD OF ASSESSING BALL MILL HEALTH USING BOND TESTS AND FUNCTIONAL PERFORMANCE * Doll1, A. Morneau2, JF. Dupont2, and D. Michaud3 1Consultant, ... Ball mill power draw 14 354 kW (corrected to pinion output/mill shell); Hydrocyclone overflow P80 µm; Hydrocyclone underflow (ball mill feed) % passing ...

Mill type (models) Diameter EGL length Installed power SAG (31) 3,80 m 9,00 m 1,90 m EGL 4,50 m EGL 400 kW kW Ball (41) 0,60 m 6,00 m 0,90 m EGL 12,00 m EGL 2,2 kW kW Rod (8) 2,40 4,60 3,60 m EGL 6,10 m EGL 200 kW kW Select scope Rotating mill structure Startup set of lining Induction drivetrain Select additions

The input variable was the ball mill's current, and the controlled variable was the circulating fan's rotating speed. Data were collected every 10 seconds, which reduced the impact of time delay. The model was adjusted with the artificial neural network, using the values of CV and MV at different times as input. The MPC was able to do problem ...

Mill, Ball, Tower, Metso, Mdl VTM3000, 3,000 HP, #D741527. Machinery and Equipment Company buys and sells used Ball Mills. Search our inventory and request a quote.

MCQ in Ball and Roller Bearings; MCQ in Journal and PlaneSurface Bearings; ... A solid cylindrical shaft cm long is used for a transmission of mechanical power at a rate of 37 KW running at 1760 rpm. The S s is MPa. Calculate the diameter ... How long will it take to mill a 3/4 " by 2" long keyway in a 3" diameter shafting with ...

The ability to simulate the Bond work index test also allows examination of truncated ball mill feed size distributions on the work index. For grinding circuits where the feed to a ball mill is sent directly to the classifier and the cyclone underflow feeds the ball mill (see Figure ), a question arises as to whether this practice will alter the ball mill work index (BW i) of the material ...

Unless the trunnion is very small or unless you are using a grate discharge ball mill, balls will not stay in the mill, and you will spend a lot on steel to add a small amount of power. ... Motor output power KW = x ( x amperage x voltage x power factor) x Rated motor efficiency/ Our power factor is electricians tell me. My ball ...

Scaleup of mills is critical to the design and operation of industrial grinding circuits. This paper presented a scaleup model based on the discrete element method (DEM) simulation to predict the performance of tumbling ball mills. The mills of different sizes partially filled with steel balls and ground particles were operated at different ...

The sorted preconcentrate will be trucked to the Copper Rand site and stockpiled by the mill building where it will be reclaimed in a hopper and fed via a single conveyor to a new 1,500 kW ball mill ( meters diameter by meters long) to be located in the 1984 expansion area of the existing mill. This new ball mill will replace the ...

The optimization of comminution circuits has traditionally relied on wellaccepted comminution laws and ore hardness and grindability indices for ball/rod mills [9,10] and SAG mills [11,12,13].These comminution models are routinely used for optimized grinding circuit design, using averages or ranges of ore hardness tests of the mineral deposits to be extracted.