Several scholars have performed the study of grinding kinetics and obtained numerous important consequences. For example, the comminution process of cement clinker followed the firstorder grinding kinetics with the balls and rod media. Meanwhile, the grinding rate of the rod mill was higher than the ball mill [22].

Cement Clinker طحن Ball Mill الشركة المصنعة الهند

By 2050, cement production in the EU is expected to remain below pre2010 levels, ranging between 165Mt and 206Mt in the FORECAST model scenarios (4), which fed the industry analysis of the European Commission's LongTerm Strategic Vision (5). Process heat overview Clinker, and clinker substitutes, are the active

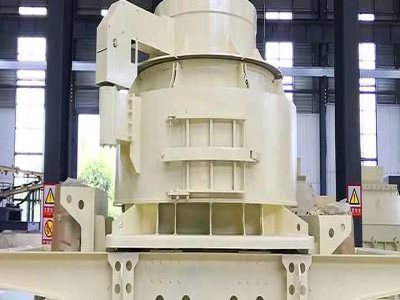

The theoretical context of slope n of RRSB particle size distribution for the ball mill and the vertical roller mill was confirmed by investigations in the tkIS technical center. The vertical roller mill produces steeper particle size distribution than a ball mill [].Earlier determination of grindability according to ZEISEL for calcined clay and clinker indicates a lower grindability for ...

The twocompartment ball mill operating in a closed circuit with a high efficiency separator is thus still the most preferred arrangement for new cement grinding installations although the vertical roller mill now has emerged as a viable alternative to the ball mill system and has increased its share of the market for cement mills over

Manufacturer of Ball Mill Cement Ball Mill, Integral Drive Ball Mill, Ball Mills and Girth Gear Pinion Drive Ball Mill offered by Chanderpur Works Private Limited, Yamuna Nagar, Haryana. ... Cement Clinker Ball Mill. Rs 45 Lakh / Piece Get Best Price. Product Brochure. Capacity (Ton/Hr) 70TPH: Condition: New: Model Number: CPG: Automation ...

Clinker ball mill used in cement industry for grinding cement . Proceeds from the mineral and exploration and crushing ore natural powder bonanza grade ore powder generated along the way, after making the actual block and made .

Figure 1 presents the design of the clinker grinding system (closed circuit), which consists of a twochamber ball mill and the separator (Plasari and T heraska, 19 81). Cement clinker is usually ...

Cement clinker is a solid material produced in the manufacture of portland cement as an intermediary product. Clinker occurs as lumps or nodules, usually 3 millimetres ( in) to 25 millimetres ( in) in diameter.

Clinker is a nodular material produced in the kilning stage during the production of cement and is used as the binder in many cement products. The lumps or nodules of clinker are usually of diameter 325 mm and dark grey in color. It is produced by heating limestone and clay to the point of liquefaction at about 1400°C1500°C in the rotary kiln.

Effects of grinding aids on model parameters of a cement ball mill and an air classifier. Powder Technol., 344 (2019), pp. 706718. View PDF View article View in Scopus Google Scholar ... Efficiency of grinding stabilizers in cement clinker processing. Miner. Eng., 4344 (2013), pp. 5257. View PDF View article View in Scopus Google Scholar [43]

Hongji is a professional production and sale of cement ball mill,cement grinding mill ball mill price have high quality and low price, welcome new and old customers to contact and inquire! ... The cement mill is the key equipment for regrinding cement clinker after pregrinding by system ingredients. Cement grinding is one of ...

The production and clinker capacity of countries in 2015 and 2016 are summarized in Table 1 [9]. China is the leader on both cement production and clinker production, accounting for more than 50% of total production. Top two countries, China and India, make up about twothirds of total cement production in the world.

A cement mill (or finish mill in . a sudden thickening of the cement mix a few minutes after mixing, . to crush the clinker prior to finegrinding in a ball mill. cyprus magento cement ball mills factory

CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volume.

In this context, Polysius® twocompartment ball mill was modeled by using perfect mixing modeling approach (Genç, 2008, Genç et al., 2013). Modifications on the circuit and the ball mill showed that, grinding capacity of the ball mill and air classification circuit could be improved by 10%.

Adbri and Cockburn Cement have announced a 199 million investment to overhaul its Kwinana cement operation with a modern state of the art facility. ... a modern ball mill circuit with two cement mills capable of grinding slag and clinker, and silo and despatch upgrades, including a 21,000tonne finished product storage area and truck loading ...

The optimim capacity that will be compatible to ball mills is upto diameter in shell. The size will be upto the flange diameter of m and height is about m. The max weight of single piece will be upto 50MT. These specifications will go well with the rod mills and ball mills.

The annual cement consumption in the world is around billion tonnes and is increasing by 1% every year [].Cement industries consume 5% of the total industrial energy utilised in the world [].A total of 40% of the total energy consumption of a cement plant is used in clinker grinding in a ball mill to produce the final cement product []. ...

This study explored the breakage kinetics of cement clinker in a labscale ball mill loaded with steel or alumina balls of 20, 30, and 40 mm sizes and their mixtures. The temporal evolution of the particle size distribution (PSD) was measured by sieving and laser diffraction. A global optimizerbased backcalculation method, based on a ...

India is the world's second largest producer of cement and produces more than 8 per cent of global capacity. Due to the rapidly growing demand in various sectors such as defense, housing, commercial and industrial construction, government initiative such as smart cities PMAY, cement production in India is expected to touch 550600 million tones per annum (MTPA) by the end of year 2025.

Optimum performance of ball mill could potentially refine Blaine fineness, thereby improving the cement quality. This study investigates the effects of separator speed and mill speed on Blaine ...

Get Price Quote. Application : Construction Feature : Easy To Use, Good Quality Packaging Size : 10100kg Material : Cement Form : Solid Packaging Type : Hdpe Bag Dear All, we have Cement portland Clinker type 2 read for sale FOB Persian Gulf Country USD per MT, Load rate is 7000 Metric Tonne per day. please contact prolinkdubai for more regards Zowj more...

A multicompartment tube ball mill in closed circuit with an air separator is very common for grinding of clinker product in most cement plants. Ardabil cement plant in northwest of Iran produces ...

Cement Ball Mill. Feeding size: ≤25mm. Capacity: /h. Functional advantages: Uniform abrasive, low energy consumption. Applications: Mainly used in cement plant, building materials, metallurgy, electric power and chemical industry, grinding all kinds of cement clinker and other materials. Email: info

The cement clinker in these studies contained a small amount of CS, ranging from % to %, and possibly in combination with other waste materials such as ashes from sewage sludge, municipal incineration and coal combustion, sewage dry powder and aluminium dross that together amounted to around 840% of the total raw feed composition, as ...

Abstract. The utilization of coal in the cement and concrete industries takes three basic forms: (1) as a fuel in the production of cement clinker; (2) ash produced by burning coal in power stations is used as a component in cement rotary kiln feeds; (3) ash produced by burning coal in power stations is used as a mineral additive in concrete ...

The energy consumption of the total grinding plant can be reduced by 2030 % for cement clinker and 3040 % for other raw materials. The overall grinding circuit efficiency and stability are improved. The maintenance cost of the ball mill is reduced as the lifetime of grinding media and partition grates is extended.

Baichy Ball Mill is a key equipment to grind the crushed materials, which is widely used in the manufacturing industries, such as cement, silicate, new build...

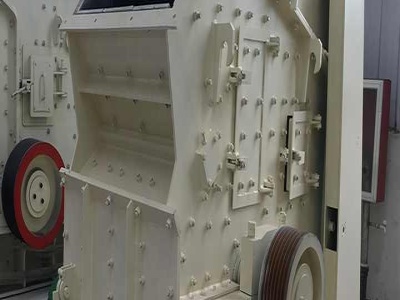

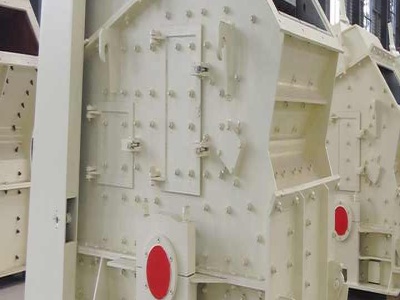

Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum rotates approximately once every couple of seconds. The drum is generally divided into two or three chambers, with different ...

A 10 MW cement mill, output 270 tonnes per hour. A cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Cement ball mills are typically twochamber mills (Figure 2), where the first chamber has larger media with lifting liners ... Clinker grain sizes depend on precrusher settings but are in some cases still up to 50mm when fed to the ball mill and therefore, it is necessary to adjust the

Contribute to chbuanjicann/ar development by creating an account on GitHub.

There are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the prepared mix in a kiln, and (4) grinding the burned product, known as " clinker," together with some 5 percent of gypsum (to control the time of set of the cement).

The various brands for Cement Clinker that one could find are Cement Clinker, IRAN, KJS, VIETNAM, TURKEY, Mine, INDONESIA.. Also, The varied grades in which Cement Clinker is available are type2, type 1, Type 1 and 2, Industrial, Type 2, I, type3.. In addition, Some of the types for packing the Cement Clinker products are Loose. Also,

Portland cement clinker is the essential ingredient . ball clay crusher . grinding or by separate grinding of slag and cement clinker with subsequent mixing. cost of cement in clinker factory Crusher|Granite Crusher .