A total of 120 t of Cristalino ore was prepared and sent to CIMM, where it was crushed and screened prior to grinding tests. The processing equipment included a m (8′) diameter by m (2′) length AG/SAG mill equipped with a 20 kW motor, a cone crusher, a m (3′) diameter by m (4′) length ball mill equipped with a 15 kW ...

يصنع SAG و BALL MILLS

In this work, the milling operation of industrial SAG mills is investigated using the Discrete Element Method (DEM). First, an industrial SAG mill with dimensions of m × m that has a ...

Ball Mills. The ball mill accepts the SAG or AG mill product. Ball mills give a controlled final grind and produce flotation feed of a uniform size. Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is ...

Assuming your ore is AGamenable: 7 TPH to 15 TPH is a comfortably production average for a 13′ x ′ AG Mill. A 13′ x 6′ SAG Mill has a reasonable range of: 20 to 30 TPH for gold ore SAG Ball Mill duty. 25 to 40 t/h for copper porphyry SAG Ball Mill duty. In Single Stage SAG duty, the approximate capacity reduces to only 8 to 13 ...

Key Benefits. Lower operating power required. Creates microcracks for downstream processes. Provides a more stable grinding operation for variable ores. Reduces the need for and consumption of grinding media.

The product from the SAG mill is further reduced in size using pebble crushers and ball mills. Hence, typical gold or copper ore requires between and kWh per ton of energy to reduce the particle size. Considering a typical mining operation processes 10,000 to 100,000 tons per day the energy expenditure in grinding is 50 percent of the ...

In fact, in four of the surveys, the SAG mill was found to be more efficient at producing circuit product than the ball mill. Similar results have been seen consistently across all the surveys where this approach has been used, including circuits with AG mills, pebble mills, HPGR, stirred mills and ball mills with fine screens. Figure 2 ...

To predict the performance of SAG and ball mills, a variety of calculations can be used. One common calculation is the Bond Work Index, which measures the energy required to grind a material from a given feed size to a specified product size. This index is used to estimate the energy required to grind ore in SAG and ball mills and is a useful ...

In a SAG mill the dimensions of the mill were m × m and the specific gravities of the mineral and that of the balls charged were and respectively.. The mill was rotated at 75% of its critical speed when 8 % of the mill volume was charged with grinding :1. The mill power drawn, 2. The maximum mill filling possible.

Ball milling is a simple, fast, costeffective green technology with enormous potential. One of the most interesting applications of this technology in the field of cellulose is the preparation and the chemical modification of cellulose nanocrystals and nanofibers. Although a number of studies have been repo Recent Review Articles Nanoscale Advances Most Popular Articles

آسیاب گلولهای یا گویآس [۱] (به انگلیسی : Ball mill) گونهای از آسیابهای صنعتی است که جهت تولید پودر نرم یا یکنواخت کردن مخلوط به کار میرود. در آسیاب گلولهای از گلولههای فولادی یا سرامیکی ...

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications. Cooling, heating cryogenic grinding.

SAG Mills and Ball Mills 911 Metallurgy Corp. subscribers 4 views 6 years ago 2 parallel SAG Mills each feeding 2 parallel Ball Mills (4 total). Around 50,000 TPD total grinding...

A milling circuit consists of a primary SAG mill that is in open circuit. This is then followed by 2 secondary ball mills in parallel. ... The product from the SAG mill is fed to the ball mills, with the product from the ball mills being combined and classified in cyclones. The underflow from the cyclones is recycled, with the overflow forming ...

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles ...

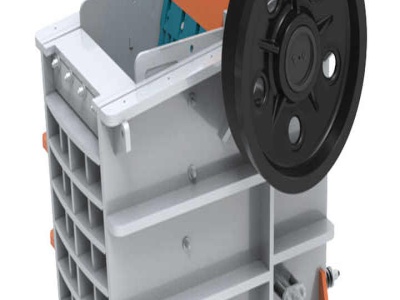

Principle of SAG Mill operation. SAG is an acronym for semiautogenous grinding. SAG mills are autogenous mills that also use grinding balls like a ball mill. A SAG mill is usually a primary or first stage grinder. SAG mills use a ball charge of 8 to 21%.[6][7] The largest SAG mill is 42′ () in diameter, powered by a 28 MW (38,000 HP ...

Objectives. At the end of this lesson students should be able to: Explain the role of ball mill in mineral industry and why it is extensively used. Describe different types of ball mill design. Describe the components of ball mill. Explain their understanding of ball mill operation. Explain the role of critical speed and power draw in design ...

the influence of these factors on speed, lining board, fill level ratio, and steel ball diameter of a SAG mill. Li [7] controlled the cone crusher's eccentric speed and closed side setting (CSS) parameters in the semiautogenous grinding process by dynamically modeling the SAG millpebble crusher loop to improve the SAG mill throughput.

ball (IGB) that will allow mill operators to measure the impact spectrum of balls and rocks in grinding mill. Second, to relate the grinding pulse to the operating conditions of the mill. Third, to use the grinding pulse as a diagnostic tool for SAG mill operation. Milestones • Test the IGB in a simulated impact

The formula for calculating critical mill of speed: N c = / √ (D d) Where: N c = Critical Speed of Mill. D = Mill Diameter. d = Diameter of Balls. Let's solve an example; Find the critical speed of mill when the mill diameter is 12 and the diameter of balls is 6. This implies that;

ترجمه مقاله در مورد آسیاهای نیمه خودشکن و گلوله ای، آماده دانلود می باشد. در این مقاله بازدهی مدار خردایش و همچنین بازدهی تجهیزات دانه بندی کارخانه تغلیظ شماره دو مجتمع مس سرچشمه مورد مطالعه قرار گرفت.

Semiautogenous grinding mills (SAG mills) are tumbling mills that most commonly have a shell diametertolength ratio of around two. With this high aspect ratio, SAG mills generate both thrown and cascading ballmilling actions with shell linings shaped to lift and to throw alloy steel grinding balls of up to 150 mm (6 in.) in diameter. These

SAG is an acronym for SemiAutogenous Grinding, which means that it utilizes steel balls in addition to large rocks for grinding. The SAG mills use a minimal ball . SAG Mill Balls Sino Grinding Industries Sino1 Balls: Sino1 balls were designed for Ø125mm (5") balls operating in +10m (33') SAG mills.

ME Elecmetal designs, manufactures and supplies the highest quality forged steel grinding media for SAG and ball mills in the world. Our extensive field experience, engineering and consulting expertise enables us to accurately analyze operational data, so we can support our customers to achieve continuous improvement in their grinding processes. The process begins when we

Overview of Ball Mills. As shown in the adjacent image, a ball mill is a type grinding machine that uses balls to grind and remove material. It consists of a hollow compartment that rotates along a horizontal or vertical axis. It's called a "ball mill" because it's literally filled with balls. Materials are added to the ball mill, at ...

Semiautogenous (SAG) mills are widely used grinding equipment, but some ore with critical particle sizes cannot be effectively processed by SAG mills and turned into pebbles. This research aims to analyze and compare the properties of raw ore and pebbles from a zinc and tinbearing ore. The results show that the contents of sphalerite, cassiterite, biotite, antigorite, pyroxferroite ...

SAG mills use a combination of steel balls and rock particles as grinding media, while AG mills use only the ore itself. Both types of mills are used for grinding ore in mineral processing operations, but SAG mills are larger in size and can grind larger quantities of ore.

Working: SAG mill make use of steel balls included with some large and hard rocks for grinding. These mills utilize the balls in making the large fragments of materials broken into pieces. The ball charge of a SAG mill is about 9% to 20%.This process takes place inside the large rotating drum of SAG mill which is filled with balls partially.

Ball Mill. The proven classical option for cement grinding. Whether employed as a twocompartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust and reliable alternative for cement and granulated blast furnace slag grinding. Used in combination with the sepol ...

Browse Metso's wide offering of reliable grinding mills: AG mills, SAG mills, ball and pebble mills, and stirred mills to fit your needs. ... Also the Premier™ mills and Select™ mills come ready to be easily integrated with our mill reline equipment and full mining portfolio providing a onestopshop for your minerals processing needs!

Ball Mill adalah suatu mesin yang berbentuk silinder (tabung) dan berfungsi untuk menggiling material kasar menjadi material yang halus. Mesin ini memanfaatkan bolabola keras untuk menumbuk dan menggesek material kasar sehingga bisa menjadi halus. Ball Mill menjadi salah satu mesin yang sangat penting dalam proses produksi di suatu industri ...

Quantum Nanostructures (QDs): An Overview. D. Sumanth Kumar, ... Mahesh, in Synthesis of Inorganic Nanomaterials, 2018 Ball Milling. A ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized balls. The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating ...

The operating principle difference between a ball mill and a SAG mill is their specific energy consumption. Ball mills use an induced storage mechanism to grind materials. The materials are ground using impact and the friction created between the particles as they rotate in a chamber.

to 15 TPH Small Scale Miner's Ball Mill. US 30,000. Mini Ball Mill. US 50,000. Ceramic Ball Mill. US 8,000. Large Batch Laboratory Ball Mill 150L to 300L. US 30,000. Large Batch Laboratory Rod Mill / Ball Mill. Sale! ... 5 to 50 TPH SAG Mill. Read more; Images for illustration purposes only. No rights can be delivered from the ...

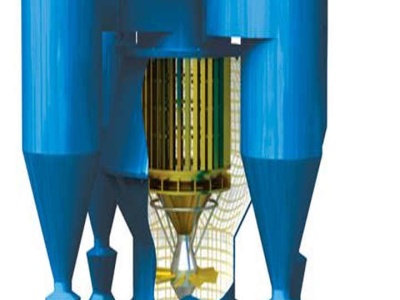

3. SAG mill fractional total filling, J t, fractional ball filling, J b, and fractional rock charge filling, Jr, ( J r = J t − J b); 4. SAG mill total feed; 5. Oversize crusher product and primary cyclone underflow; and, 6. SAG mill fresh feed, including the feed sizes ( F 80. . . F 20). Step 1: Oversize Crusher Feed, Primary Cyclone Feed and ...