Traditionally vertical roller mills operate with feed around 80—100 mm size but reducing this to lower size has proven beneficial to capacity enhancement in number of plants; with ball mills the ...

الحمل المتداول VRM و Ball Mill

Dr. John Mills is a General Surgeon in Palo Alto, CA. Find Dr. Mills's phone number, address, insurance information, hospital affiliations and more.

phosphate materials. The status in successful hard rock applications of the VRM technology, such as Foskor (Phalaborwa) and EuroChem (Zhanatas), is presented. Selected performance data is reported and compared to results of conventional ball mill circuits. Figure 1 LM with elongated classifier at Phalaborwa, Foskor

The sample was received crushed appropriately for the ball mill test. Ball Mill Grindability Test was conducted by standard practice using 100mesh (150 pm) closing screens. The ball mill work index is shown below. BM Wi (kWhr/st) = ; BM Wi (kWhr/mt) = ; Bond Ball Mill

A pilotscale Loesche VRM was used to determine the power required to grind 100 t/h of the same limestone as used at Kusile (work index of 12 kWh/t) with a top size of 19 mm to a 85% and 95% passing 45 µm product. A significant power saving of % was observed for the dry VRM compared to the wet ball mill (% for the circuit).

Varied types/geometries of stirred mills have been produced by different manufacturers, and the comparison task has been accomplished for some of the technologies,, Tower mill vs IsaMill. However, the main drawbacks of these comparisons were the uncommon characteristics of the milling environment, such as media size. In this study, HIGMill and IsaMill, which were vertically and ...

Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materials. The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system. However, despite these benefits,

Vertical roller mills (VRM) are widely used to grind, dry, and select powders from various materials in the cement, electric power, metallurgical, chemical, and nonmetallic ore industries. For the sectors above, the VRM is a powerful and energyintensive grinding field [1], [2]. It is used to grind slag, nonmetallic ore, and other block and ...

تحميل و شرح ميتاتريدر 5 بطريقة مفصلة لخصائص منصة Metatrader 5 لجعل تداولك أسهلاً من أي وقت مضى! ... عبارة عن نقاط توقف سيتم ضبطها عندما تتحرك الصفقة لصالح المتداول، لتقليل مخاطر الجانب السلبي بحدوث ...

على سبيل المثال، إذا كان المتداول يخصص 3% من محفظته لأسهم آبل و2% لأسهم تسلا، فسوف تتبع محفظتك الاستثمارية نفس النهج. هذا لأي سوق أسهم أو العقود مقابل الفروقات. التعاملات المالية

The global Ball Mill (Mining) market was valued at US Mn in 2018 and is projected to increase significantly at a CAGR of % from 2019 to 2028. Ball Mill (Mining) Market Scope: By type, the market is segmented into Wet grinding Ball Mill and Dry grinding Ball Mill. By application, the market is divided into Metal Mining and Mineral Mining.

If your Economics permitts for this additional cost, Than you can choose VRM for Cement grinding also. Secondly, The Initial cost is Approx. Thrice if compared with Ball mill, if you have good cement market permitts you for the payback within 2 Years. Power consumption in ball mill is around 3233 unit/ton, whereas in VRM it will be around 1620 ...

ولا توجد استراتيجية ناجحة أو نهج يعمل طوال الوقت ويأتي بالأرباح، إن الشئ الرئيسى للنجاح في التداول هو الانضباط بغض النظر عن كيفية استثماره، الانضباط فى إعداد خطة التداول وتنفيذها على النحو ...

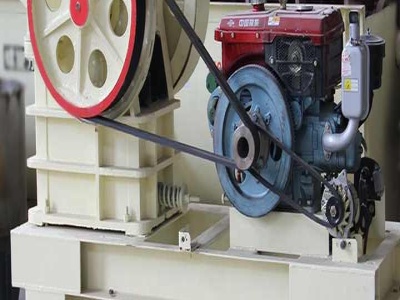

The ball charge typically occupies around 30%36% of the volume of the mill, depending on the mill motor power and desired energy consumption and production rates.

A VRM is a compact unit, making the footprint of the installation smaller and reducing the civil engineering costs when compared to a ball mill system. Savings are also made due to the method of construction of the two systems. Ball mills are built at the supplier's factory and transported to the cement producer's site.

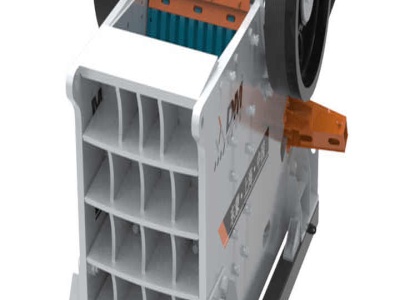

Ball Mill. The proven classical option for cement grinding. Whether employed as a twocompartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust and reliable alternative for cement and granulated blast furnace slag grinding. Used in combination with the sepol ...

جودة عالية غير القابل للصدأ والدليل على المياه لفات الصلب مزورة للمطاحن المتداول الساخنة ، وارتفاع ارتداء المقاومة من الصين, الرائدة في الصين مجموعات من الصلب للبناء معدنية,الإطار الصلب أطقم البناء المنتج, steel frame ...

With the introduction of the high compression machines such as High Pressure Grinding Rolls (HPGR), Vertical Roller Mills (VRM) and Horomills, efficiency of the grinding circuits was improved in terms of energy and downstream effects. Among these devices, vertical roller mills have an important position in cement and mining industry.

A specially designed laboratoryscale VRM was constructed in the powder research center in Hefei, China. Fig. 1 represents the schematic diagram of VRM utilized in the experiment and DEM simulations. The diameter of the millstone and grinding roller are 600 mm and 340 mm respectively, and the angle between the centerline of the grinding roller and the horizontal is 13°.

solutions and implementing them in order to increase the output of vertical roller mill. This study can benefit the organizations using VRM and are not able to utilize its full productivity due to some bottlenecks or constraints. 1. Introduction India is the world's second largest producer of cement and produces more than 8 per cent of the total

هل يعمل تداول تدفق النظام؟. تداول تدفق الطلبات هو استراتيجية تداول مثبتة يستخدمها المتداولون العاملون في الشركات التجارية. سوف يمنحك التداول باستخدام استراتيجيات تدفق الأوامر وسلالم ...

The discharge port of the wet ball mill is trumpetshaped and has a builtin screw device for easy discharge. Most of the ball mills sold on the market are wet ball mills with high grinding fineness and a good beneficiation effect. 3. Matters needing attention in the process of choosing dry and wet grinding

Different specification of roller mill so the K1 is different. K1 of Loesche Mill series roller mill is and for Atox Mill is 7 and for. MPS Mills is D is the table diameter. Example for MPS 2800 mill with table dia G = * = ~ 50 tph. ffVRM Hydraulic Operation.

Figure 1: Specific power consumption of ball mill system v/s vertical roller mill system for OPC grinding Ball mill system Loesche Power consumption [kWh/t] VRM system 20 40 60 80 100 120 140 160

In conclusion, the application of vertical roller mill technology in the cement industry has revolutionized the way cement is produced. VRMs are more energyefficient, ecofriendly, and produce a more consistent product compared to traditional grinding mills. They are also more suitable for use in urban areas due to their lower noise level.

Ball mill for cement grinding EXCEL™ premium trunnionsupported mill parts FT Series Mill LoadIQ Smart sensor technology Mill liner wear measurement and prediction services ... The vertical roller mill (VRM) is firmly established in cement plants all over the world. The biggest issues facing plants are not due to the equipment itself, but ...

The vertical roller mill itself is equipped with a powder concentrator, which can remove fine powder in time, reduce the phenomenon of overgrinding and improve the grinding efficiency. The vertical roller mill is less power consuming. The energy consumption of a vertical roller mill is around 75% of that of a ball mill of the same capacity.

Pfeiffer Progress is our Tradition. Gebr. Pfeiffer SE. Barbarossastr. 5054. Phone: +49 (0)631 4161 0. 67655 Kaiserslautern. Fax: +49 (0)631 4161 290.

Vertical roller mill (VRM) is a largescale grinding equipment, which is used to grind raw materials from block/granule into powder. ... VRM, Horomill and multichamber ball mill closed circuits ...

Vertical Roller Mill (VRM), a cutting edge technology, can be installed to grind the hard, nodular clinker from the cement kiln instead of inefficient ball mills that can save up to 15% energy [63]. Inclusion of flexible speed drive used for cooling purpose can further reduce electricity consumption.