The sample was received crushed appropriately for the ball mill test. Ball Mill Grindability Test was conducted by standard practice using 100mesh (150 pm) closing screens. The ball mill work index is shown below. BM Wi (kWhr/st) = ; BM Wi (kWhr/mt) = ; Bond Ball Mill

فرق Bitween VRM و Ball Mill

VRM AND BALL MILL PRODUCT COMPARISONS To compare the similarities or differences between cement mill products of the same composition but produced in a vertical roller mill or ball mills, samples from each of the plant's mill types were taken and tested. All samples were obtained while the mills were producing the same product. VRM

. hammermill drotsky pc24 complete r20,000 .Vertical Roller Mill Ball Mill . . Te Koop, Crusher Mills .Mls3726 Vrm . powder ball mill . best way to run a ball mill with gold ore

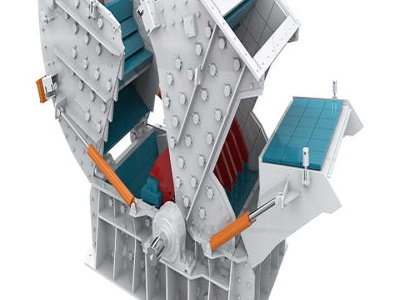

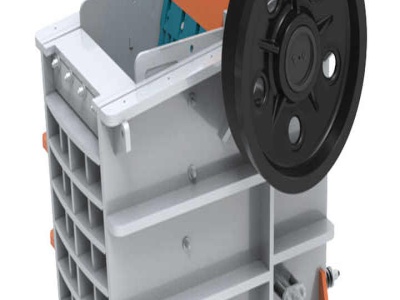

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles ...

Vertical Roller Mill The vertical roller mill (VRM) shown in Figure 4 is an air swept, mediumspeed, vertical pulverizer with integral classifier. It pulverizes coal by applying hydraulicallyloaded grinding pressure through three grin ding rollers onto a rotating bed of coal. Grinding pressure can be adjusted to account for variations in coal

Optimum performance of ball mill could potentially refine Blaine fineness, thereby improving the cement quality. This study investigates the effects of separator speed and mill speed on Blaine ...

19 Tikaria_Mill HGRS SEPT07 Workshop Statistically every 2nd VRM reducer fails. Holcim vertical roller mill distribution vs. reducer damages. 100 This seriously 93 ... Central or Girth Gear Drive for Ball Mills 1. Central or Girth Gear Drive for Ball Mills 1. Vishnu Vardhan . C.

VRM vs Ball Mill for Cement Grinding Page 1 of 1. Feb 10, 2016 · re VRM vs Ball Mill for Cement Grinding. Specific power consumption high for ball mill and Low for VRM ; Maintenance costs high for VRM and low for Ball mill ; Process control/process technology ball is operation friendlt and simple in operation but VRM requires some PID or .

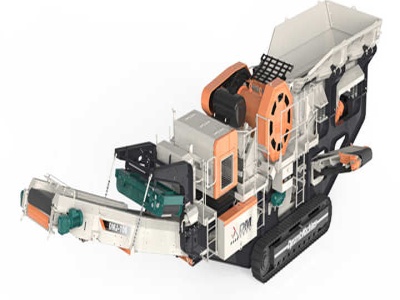

Advantages at a glance: Modular design and small footprint enable integration in existing grinding plants. Production increase in range of 1020 %, depending on the fineness, especially for smaller ball mill systems up to 100 tph. Quality improvement by use of the additional grinding stage, for example to improve the early strength while maintaining the original production rate

CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volume.

FIRST VERTICAL ROLLER MILL FOR CEMENT GRINDING By: Mark Simmons . several benefits compared to the ball mill in regards to operating costs and flexibility. Ball Mill vs VRM Scribd Ball Mill VS VRM Expecting Experts opinion regarding Advantage Disadvantage (Quality, Production, Current consumption, Man power, etc.) SUNILUnfollow Follow ...

Differences between Cement Ball Mill and Vertical Cement Mill Grinding Mechanism. The grinding mechanism of a ball mill is a series of impact and attrition events that occur inside a large rotating drum. The grinding media collide with each other and the material being ground in the drum, creating a large amount of heat.

Comparison Between Ball Mill And Vrm bitween vrm and ball mill ball mill comparison with vertical roller mill. As we all know that the vertical roller mill and ball mill can be used in superfine stone powder making, the powder fineness made by ball mill can be controlled between 80 mesh to 400 mesh; however the vertical roller mill process ability can be adjusted ...

What's more, our online condition monitoring services enable you to adopt a proactive maintenance strategy for your OK™ and ATOX® mills that eliminates unexpected downtime and ensures continuous high performance. Our highlyflexible vertical roller mills (VRM) are energysaving grinding solutions that cater for differing types of material.

difference between vrm and ball mill . Dipl Ing Th Fahrland Dr Ing K H Zysk Loesche . Mill offer significant advantages over ball mills in terms of their energy efficiency As noted in a current publication 1 the specific power consumption of a ball mill is higher than that of a vertical roller mill VRM carrying out the same oper ations by a factor of between 1 5 and 2 depending on the

FlyAsh Blaine: Increase fly Ash Blaine from 290 to 320. Flyash is a major supply for any cement plant now a days because every producer wants to produce. more PPC than OPC due to profitability ...

Traditionally vertical roller mills operate with feed around 80—100 mm size but reducing this to lower size has proven beneficial to capacity enhancement in number of plants; with ball mills the ...

differencebetween vrm and ball mill. CEMENT INTERNATIONAL 4 2/2013 4 VOL 11 67 PROCESSING If a similar product to one from an existing ball mill system is needed, however, the VRM can be adjusted to...

than ball mills, even if the ball mill is combined with a roller press. This and further arguments led to the increased share of VRM for the grinding of finished cement. Taking into account that VRM usually have a bigger output than ball mills, it can be declared that the major part of the cement production with newly installed mills comes from ...

Because the VRM is more efficient VRM 3700 2:00 4:30 these benefits are realized without the large Ball 3900 2:00 4:20 penalties to power consumption seen in ball VRM 3900 1:30 3:45 mills. The overall balance of PSD, strength development and power consumption make it possible to maintain low power usage while TABLE 3: Comparative Setting Times ...

difference between vrm and ball mill in cement plant tecnology. Confederation of Indian Industry Ireda Alternately, they may approach for technology upgradatioon, Huge gap between supply demand b, The detailed ....

The raw vertical roller mill has four rollers, 3000 KW main drive, m table diameter, m roller diameter with 330 t/h capacity (made by LOESCHE Company from Germany).

The difference between ball mill and vertical mill in cement grinding Over the last three decades the vertical roller mill has become the preferred ball mill for grinding of raw materials. The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a ...

If your Economics permitts for this additional cost, Than you can choose VRM for Cement grinding also. Secondly, The Initial cost is Approx. Thrice if compared with Ball mill, if you have good cement market permitts you for the payback within 2 Years. Power consumption in ball mill is around 3233 unit/ton, whereas in VRM it will be around 1620 ...

Open sidebar. chengxinjia; sbm; Repository

The standardised design allows you to use the drive unit in all types of mill optimal for vertical roller mills. Oil supply unit keeps the gear unit running smoothly. The oil supply units for our vertical roller mill gear units and drive systems includes lowpressure pumps to feed bearings and gears with filtered and cooled lubrication oil.

Contribute to yunan88/crusher development by creating an account on GitHub.

The industry best in energyefficient grinding, the OK Mill uses five to ten percent less power than other vertical roller mills and 30 to 50 percent less energy than conventional ball mills. Easy operation and maintenance. Worn roller grinding surfaces can either be replaced or rewelded inside the vertical roller mill.

merits and demerits of vrm and ball mill Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even VRM usually have a bigger output than ball mills, it can be declared that the major part of the cement production The main disadvantage of Slag Cement is the VRM are meant for grinding slag since the specific advantages of .

印度尼西亚语的一些资料备份. Contribute to sbmboy/id development by creating an account on GitHub.

The HPGR and air classification circuit used 20 30 % less energy than the HGPR, screen, ball mill circuit. While VRM was estimated to use 10 30 % less energy (depending on the type of VRM ...

Ball mills for cement raw material and coal equipped with a drying compartment adequately air swept with hot gas (/sec above the ball charge), can handle moisture about 8%. Fully air swept mills (56M/sec) can dry up to 1214% moisture. Grinding Operation Objectives and KPIs: Highly energy intensive unit operation of size reduction in ...

4. Grinding process. In the ball mill, the material is mainly crushed by impact and friction. In the vertical grinding mill, the material is mainly extrusion, and grinding is the auxiliary. The residence time of the material in the vertical mill is 23 minutes, while in the ball mill it takes 1520 minutes.