Product Size: All passing 6 mesh with 80% passing 20 mesh. Net power from pilot plant: KWH/ST. Mill, gear and pinion friction multiplier: Mill Power required at pinionshaft = (240 x x ) ÷ = 5440 Hp. Speed reducer efficiency: 98%. 5440 Hp ÷ = 5550 HP (required minimum motor output power).

SAG Mill Plants Manufactures

Vedanta Project in South Africa 1 SAG mill, Ø× 1 ball mill, Ø× CITIC HIC is an experienced company specialized in designing and manufacturing mineral processing equipment, including grinding mills, crushers, vertical stirred mills, mine hoists, rotary kilns, etc.

One process variation that has become increasingly established in recent years is the combination of AG or SAG mill with a ball mill and a downstream agitated ball mill (Fig. 4). The second grinding circuit is effective especially in flotation plants to obtain the finenesses required for the flotation stages, which often necessitate regrinding ...

The voltage reduction magnitude is between 10% and 90% of the normal root mean square (RMS) voltage at 60 Hz. The duration of a voltage sag event, by definition, is less than 1 min and more than 8 msec, or a half cycle of 60Hz electrical power. RMS voltage variations include interruption, swell, and sag (Fig. 1.).

The testwork to be conducted should also replicate the mode of breakage occurring in a SAG mill. Pilot plants testwork (typically having m of diameter) are good in that respect but require a large amount of samples (sometimes not yet available) and are very expensive. ... It would get destructive if manufacturers start requiring to do ...

The three gearless mill drive (GMD) systems are the ABB most powerful ever made. The GMD for the 40foot SAG mill has a power rating of 28 megawatts (MW), and the GMDs for the two 28foot ball mills have a power rating of 22 MW. They are the largest diameter and most powerful SAG and ball mills drive systems at the highest altitude installed to ...

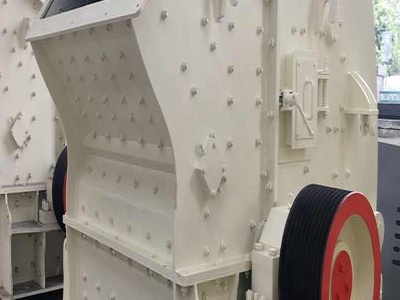

Since there are not that many small SAG mill operations of under 2000 TPD, and most sub2000 TPD mills are built with rod mills and/or ball mills only; the upstream crusher plant needs to have sufficient crushing power to provide a P80 to grinding of typically <″ (40 mm) and often as finely crushed as <3/8″ (9 mm).

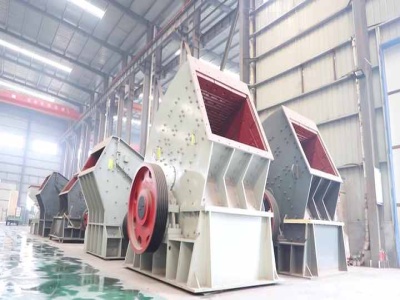

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher can be up to about 8:1. Feed: ROM up to m. Product: 300mm (for transport) to 200mm (for SAG mill) Feed Rate:

The application of autogenous/semiautogenous (AG/SAG) mills is widespread in industrial mineral processing plants as first stagegrinding units for ore size reduction, mineral liberation purposes, and economic benefits [1,2,3].These mills are used for grinding large quantities of ores of varying characteristics, which presents control challenges.

Singlestage SAG mills can be very beneficial in reducing capital costs for plants with a staged throughput approach, according to FLSmidth, which markets the FullerTraylor line of SAG mills that range from 14 to 40feet (ft) in diameter. When future tonnage needs to be increased, the SAG Mill can feed downstream ball mills to boost capacity.

• 28 MW GMD for a 40' SAG mill • 28 MW GMD for 42' SAG mill Whether it is size or an installation at the highest altitude (4600 ), ABB's GMDs are well positioned to contribute to the building of larger and ever more powerful mills. — Leading the gearless mill drive evolution The ABB gearless mill drive (GMD) is the most powerful ...

Mining engineers, Peter von Rittinger, Friedrich Kick and Fred Chester Bond independently produced equations to relate the needed grinding work to the grain size produced and a fourth engineer, suggested that these three equations might each describe a narrow range of grain sizes and proposed uniting them along a single curve describin...

Increase the productivity of your cement plant. Are you looking to invest in a new plant, increase the capacity of an existing site, or investigating productivity improvements? As a full flowsheet provider with more than 135 years of experience in the cement industry, we are ready to assist you through the entire lifecycle of your plant.

The mill body consists of an allwelded mill shell and a Tsectional weldedup slide ring at either end, the cylindrical part of which is welded onto the ends of the shell. The mill shell has four manholes, two for each grinding compartment. Slide shoe bearings. Much simpler foundations and reduced installation height lower civil costs

SAG mills, rod mills and ball mills are the classical pieces of grinding equipment employed in gold recovery plants. There is an increasing trend to employ SAG mills (semiautogenous mills) in place of secondary and tertiary crushing and primary grinding. The most common type of rod mill is the overflow mill. There are two typed of ball mills used.

Type CHRK is designed for primary autogenous grinding, where the large feed opening requires a hydrostatic trunnion shoe bearing. Small and batch grinding mills, with a diameter of 700 mm and more, are available. These mills are of a special design and described on special request by all Ball Mill Manufacturers.

PilotScale SAG Mill Facility Will Help to Optimize Charge Motion and Slurry Flow in PlantScale SAG Mills Reducing Energy Consumption The mining industry operates approximately 80 semiautogenous grinding mills (SAG) throughout the United States.

The LSTM network shows great results on predicting the relative operational hardness at 30 min time support. On SAG mill 1, using a lambda value of, the obtained accuracy was % while increasing the lambda to led to an increase in accuracy of %. Similar results were found on the second SAG mill.

Our innovative product development and manufacturing processes have been developed to produce a range of milling instrumentation, consumable products and process optimisation services tailored for any milling configuration. ... operates a gold plant in Australia comprising of a crushing and grinding circuit (SAG mill with a closed loop cyclone ...

Product Details Working Principle Relevant Projects Technical Data Material Application AG Mill and SAG Mill Details AG mill (autogenous mill) is a mediumfree mineral grinding equipment. The raw ore and the coarsely crushed ore are directly fed into the AG mill. No other medium is involved in grinding.

SAG mills and AG mills are both commonly used in mineral processing operations, but they operate in different ways and have unique characteristics. In this section, we'll explore the main differences between SAG and AG mills, including their definition, operation, design, and applications.

However, this trend also makes manufacturing processes and equipment more vulnerable to realworld power quality conditions. Power quality is related to fluctuations in the electrical supply in the form of ... show up in the forms of plant downtime, equipment replacement, lost work in process, additional labor, and possibly missed shipment ...

FLSmidth has fully engineered a new range of trommel frames and screen media for SAG Mills, ball mills and scrubbers. As your partner in productivity, we combine our indepth knowledge of equipment and applications, providing a comprehensive approach to improve your processes. ... These standard dimensions allow us to supply your media from any ...

Process optimisation for your SAG Mill Total Cost of Ownership Tool Back. QCX® Advanced Quality Control Systems ... In both the cement and mining industries, there is a push to do more with less. For cement manufacturers operating in highly competitive markets, it is vital that your business operates as efficiently and costeffectively as ...

The processing plant operates with a standard SABC comminution circuit, and was the first to use the largest domestic Φ × m SAG mill ('diameter' represents nominal diameter, and 'length' of the mill represents the effective grinding length inside the end liners and discharge grates), Φ × m overflow ball mill and ...

Manufacturers in the "big mill business" have long ago recognized that simple extrapolation of existing designs from smaller mills is poor engineering at best.

Despite the differences in scale between the 450 mm test and the m pilot plant tests (along with differing circuit closing sizes, and varying pilotplant operating conditions), the similarity in distributions of unit power requirements reinforces the concept that SAG throughput is defined by a specific unit power requirement.. 3. Drilling and Blasting

A lime slaking and addition system can consists of two systems to control the pH in the rougher and cleaner flotation pebble lime silo will dose dry lime to the SAG mill feed belt; a hydrated lime make down system will provide slurry lime to multiple addition points in the flotation circuit. Other lime delivery options are detention slakers and Vertimill slakers.