This newlydeveloped coal mill model provides a valuable tool that can be used to improve the pulverizer design and optimize unit operation. For example, reject coal rate, which is controlled by ...

B H e l make coal mill

mill / sbm xrp 763 783 803 coal mi.... 25 KiB Raw Permalink Blame History Permalink Blame History

The coal mill grinding system is an important part of the dry process cement manufacturing. In cement plants, we usually adopt the air swept coal mill system or vertical mill system as the pulverized coal preparation system, which is arranged at the cement kiln head or kiln tail to provide fuel for clinker calcination. However, due to the flammable and explosive characteristics of pulverized ...

CO2 emissions from coal power generation could be reduced by maximizing the amount of torrefied biomass that can be used in pulverizedcoalfired power plants. In this study, to evaluate the milling performance of coal and torrefied wood pellets (TPs), various blend ratios were tested using a benchscale roller mill. Neutral sugar analysis was performed to evaluate the biomassderived part of ...

A typical feeder used to deliver coal to a BW Etype mill is a Stock volumetric or gravimetric feeder. For a volumetric feeder coal feeder density is assumed to be of constant nature. A gravimetric feeder weighs the ... A typical ring life for a Kriel BW mill is 60 000 operating hours. This equates to a wear rate of 980 hrs/mm.

Coal pulverizer Power Plant #boiler #mechanical coal mill Operation maintenance Question Answer for interviews #thermalpowerplant

Engineering. Basic and detailed discussion on Coal Mill (Raymond) and Air Fans Performance in a Thermal Power Plant. Gives an idea as to how the performance of Coal Mills and fans can be improved. Manohar Tatwawadi Follow. Consultant at total output power solutions. TPS Coal Mills and Fan Performance Download as a PDF or view online for free.

500 MW BOILER OF CHANDRAPUR T. P. S. 500MW Boiler at is supplied by The boiler is described as: Controlled Circulation with rifled tubing, single drum, balanced draft, radiant reheat, dry bottom, coal fired boiler, top supported. It is a tangentially fired boiler with tilting burners. The salient features of this boiler ...

Modeling of outlet temperature of the coal mill. On the basis of the energy balance inside the coal mill, the model of the coal mill outlet temperature is established as shown in Eq. (12). (12) C mix M c + M pf + M metal θ out = Q in − Q out. The magnitude of Mc and Mpf is 10 1 while that of Mmetal is 10 3.

About | Services | Locations | Contact us | Terms | Login Services | Locations | Contact us | Terms | Login

NAME MINE / MILL COMPANY page county metal/coal 1879 AITKEN, L L DANTE GOLD MINING 175 Teller m 1910 AITKEN, L L DES MOINES GOLD MINING 175 Teller m 1910 AITKEN, L L TEXAS GIRL GOLD MINING 206 Teller m 1910 AKERS, I N AMERICAN 246 Hinsdale m 1879 ALBERTO, ANTONIO ALBERTO 350 San Juan m 1879 ALBRIGHT, F C POMEROY, M M 110 Boulder m 1879

over range, low airtocoal ratio, ability to pulverise a wide range of coals, virtually unaffected by foreign material and the flexibility of available capacity. Tube mills suitable for catering to coal throughput from 30 TPH to 110 TPH. Bowl Mill is basically a vertical Mill rotating at Moderate speed (30 to 60

LM Vertical MillHigh drying efficiency, Low running cost, Good environmental effectLM Vertical Mill integrates crushing, drying, grinding, classifying and co...

YES. Our boiler mills and coal pulverizers span the globe and are built in a variety of sizes and capacities. We provide customized maintenance solutions, and offer a full spectrum of highquality solutions for each—in addition to our thousands of standard boiler mill parts and boiler service solutions. This is the Power of Yes.

Coal Bunker in Thermal Power Plant 500 MW Boiler | Conveyor Belt | Ventilation Fan | Coal Mill #CoalBunker #CoalMill #explorewithhasnainYour query*What is co...

1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin. 1953 500th coal mill plant sold worldwide. 1961 Introduction of hydraulic spring assembly system. 1965 Construction of first pressure mill (LM D). 1980 Delivery of first modular coal mill (LM D). 1985 Delivery of first selfinerting coal grinding plant (LM D) for the steel industry (PCI ...

One of the objectives of the pulverizer coal in such systems is to reduce the coal particle size so that 7080% passes through a 200 mesh (75 μm) screen (summary after Scott, 1995). Pulverizing is accomplished in several different ways, including grinding with large steel balls in a bowl mill.

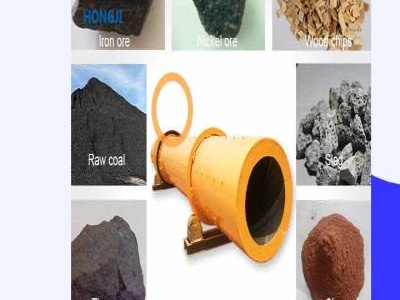

A coal mill works by grinding coal into a fine powder using large metal rollers. This process is used to create precise particle sizes as required by the application. The coal is fed from the ...

Pulverized coal Intermediate air Flue gas resuction duct. Oil burner. Pulverized coal Lower air Ceramic nozzle. Pulverized coal duct. Raw coal chute. Pulverized coal duct. Beater wheel mill. 031 010p Size and Capacities of ALSTOM Beater Wheel Mills (General View) Mill type Rated throughput Motor rating. N t/h. 26 11. 60 30 280. 80 40 380. 120 ...

The coal mill can also grind petroleum coke and anthracite down to a fineness below 5% +90 micromillimeters (mm) when coupled with a variable speed mill motor. No sticky situations The ATOX® Coal Mill can grind and dry raw coal with up to 25 percent moisture level. By adjusting the gas flow stream with the nozzle, you can deal with more ...

In the first computational example the coal pulverizer drive system is considered. This machine is driven by the 22 kW asynchronous motor by means of the reduction planetary gear of the resultant ratio 1: static characteristic of this motor as well as the drive system first torsional eigenform of frequency Hz are shown in Figs. 2a and 2b, respectively.

Abstract. CO 2 emissions from coal power generation could be reduced by maximizing the amount of torrefied biomass that can be used in pulverizedcoalfired power plants. In this study, to evaluate the milling performance of coal and torrefied wood pellets (TPs), various blend ratios were tested using a benchscale roller mill.

BW's pulverizers, found at power stations throughout the world. From our original E/EL ballandrace type pulverizers for lower capacity applications, to the latest BW Roll Wheel™ pulverizer capable of grinding up to 230,000 pounds of coal per hour (104,300 kg/hr), we set the standard for high availability, reliability and low maintenance.

Operation. The coal is feed into the coal mill through a central inlet pipe where gravity is used to lead the coal to the bottom of the mill, where the grinding table and some heavy rollers pulverizes the coal to particles. The primary air flow to the furnace is fed through the mill, with the purpose of heating and lift the coal particles out ...

Contribute to crush2022/mill development by creating an account on GitHub.

Get Coal mill overhauling Tenders and Find Out Latest Updates About ETender Coal mill overhauling Tenders in India. Download Coal mill overhauling ETender Documents Notices for Free. 79909 34844

(1) The predictions of outlet primary air temperature, mill differential pressure and electric current fit the actual measured data well. RMSE and MAE of the proposed model are all lower than those of the previous model when predicting the P m i l l and I, therefore, the proposed model gets better prediction accuracies from a holistic of raw coal moisture soft sensing, the ...

1. Introduction. Duplex inlet and outlet ball mills are widely used in 200300 MW coalfired generating units. This pulverizing system is easily adaptable to multiple coal type and is simple to operate, thus it is suitable for pulverizing coal with low grindability, high abrasiveness and required degree of fineness.

Bituminous coal A Steam generator B Steam lines C Coal bunker D Mill feeder E Coal mill F Burnout grate G Ash removal H FD fan a A Steam generator B Steam lines C Coal bunker D Mill feeder E Coal ... Boilers. Pulverized coal boilers fire finely powdered coal, typically with an average particle size of about 25 µm ( in). Coal burns in ...