The mass ratio of air to coal is dependent on the coal mill manufacturer and usually ranges from to with a typical value of An air to fuel mass ratio of produces a primary stoichiometric ratio of approximately, or 16% of the air necessary for complete combustion of the coal.

Sistem Coal Mill Cement

In this technical article electrical systems in cement plant will be touched upon. All machines are driven by electric motors. Majority of the motors are 400 440 volts. A selected few motors of higher ratings are MV motors with 3300, or 6600 or 11000 volts. Most motors are fixed speed and unidirectional motors.

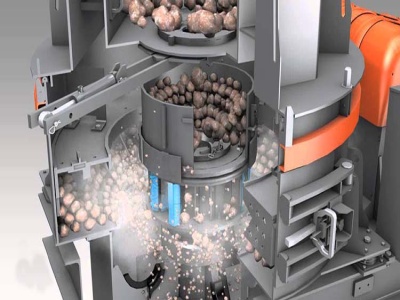

Coal mill. The coal mill uses coal, coke or grinded pet coke with different size of balls. Larger sized balls are used for impact grinding and the smaller balls are used for attrition grinding. Cement mill. This is the final step in a cement manufacturing process. In this step, the clinker is ground together with additives in a cement mill.

Cement plants operating at the 50th percentile perform at the midpoint for the industry, while plants operating above the 50 ... Petroleum Natural Gas Systems, Waste, Underground Coal Mines, Universities, Military, and Use of Electric Equipment. CO 2 e emissions include Methane (CH 4), Nitrous Oxide (N 2 0), process emissions and other gases ...

FLSmidth is the full flowsheet technology and service supplier to the global mining and cement industries. ... Silo/Filter Probe System for coal mill Spare and wear parts for gas analysis systems Back. Continuous Emissions Monitoring Systems (CEMS) Back. Dust monitors. Back. Flow monitors. Back. ReportLoq emissions reporting system ...

LOREM IPSUM 1. Lorem ipsum dolor sit amet 2. Consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. 3. Ut enim ad minim veniam, quis exercitation

Coal mill: 74: 18 [21], [41] Farina mill: 84: 25 ... Eksergeticheskie raschety tekhnicheskikh sistem: spravochnoe posobie [Exergy calculations of engineering ... Investigation of effect of varying deadstate temperatures on energy and exergy efficiencies of a Raw Mill process in a cement plant. International Journal of Exergy, 6 (2009), pp. 655 ...

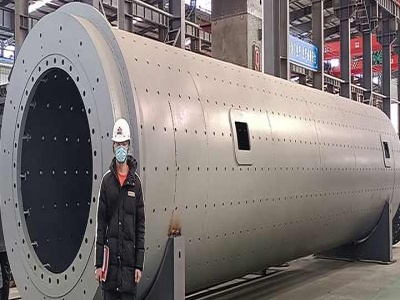

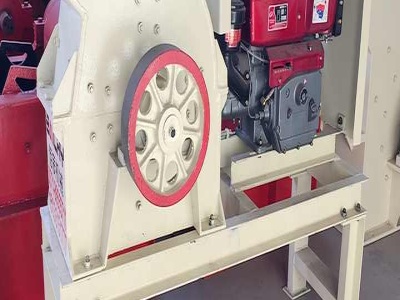

Coal Mill in Cement Plant A coal mill is also called a coal pulverizer or coal grinder. It is a mechanical device used to grind raw coal into pulverized coal powders. The most used coal mills in cement plants are airswept ball mills and vertical roller mills.

Raw Mill 19. Cement Packing and Load Out ... Coal mill 21. Dormitory 10. Blending silo 22. Central Office 11. Suspension Preheater 23. Utilitas . 46 Pengambilan data dilakukan di Central office, section of maintenance planning PT. Semen Indonesia (Persero) Tbk Pabrik Tuban. ... Penerapan sistem FMEA baru diterapkan tahun 2015 akhir hingga saat ...

Pneumatic conveying systems and equipment. Our experience your benefits. We are a world leader in the design and supply of pneumatic systems for dry bulk materials. Our products and systems hold longstanding patents on several wellknown technologies, and provide clean, safe and cost effective solutions for many diverse applications. Services.

9.© Confederation of Indian Industry Case StudyABC plant Overall Mass Balance Basis : kg/kg clinker. Input Streams (kg/kg clinker) Kiln Feed Input Cooling Air Primary Air Fuel Consumption Coal Conveying Air Input Moisture Water spray Total Output Streams (kg/kg clinker) Clinker 1 Cooler Vent Air Preheater gases ESP return dust ...

Portland Cement Manufacturing Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites. More than 30 raw materials are known to be used in the manufacture of portland cement, and these

Refusederived fuel (RDF) from municipal solid waste (MSW) is an alternative fuel (AF) partially replacing coal/petcoke in a calciner/kiln of cement plant. The maximum thermal substitution rate (TSR) achieved through RDF is 80100% in the calciner, while it is limited to 5060% in the kiln burner. Different AF precombustion technologies, advancements in multichannel burners, and new ...

Pulverized Coal Combustion. PCC technology is a widely utilized technology to generate energy from fossil fuel, especially coal [15]. In this technology, pulverized coal is injected to combust in a furnace in the presence of a controlled level of air. The heat generated is used to produce highpressure steam driving a steam turbine to ...

Coal Mill in Cement Plant A coal mill is also called a coal pulverizer or coal grinder. It is a mechanical device used to grind raw coal into pulverized coal powders. The most used coal mills in cement plants are airswept ball mills and vertical roller mills.

Kiln and Coal Mill Operation In Cement Plant _English VersionIn the previous video session, we explained how to start the Kiln operation, but the quality and...

akhirnya menjadi klinker melalui sistem pendinginan dan alat transport untuk didimpan ke Klinker Silo (Novrizal, 2017:II18). Proses pembakaran menggunakan bahan bakar batu bara yang telah digiling dan dikeringkan melalui Coal Mill. Klinker sebagian digunakan ke Cement Mill Baturaja dan Cement Mill Palembang dengan angkutan Kereta Api

Waste to energy frees up your cement plant to burn your preferred fuel without compromising function. Impressive substitution rates with difficult alternative fuels The HOTDISC Reactor is designed to achieve a calciner fuel substitution rate of up to 80%, although results vary significantly depending on specific plant conditions.

The cement rotary kiln. When operating the vertical roller mill, the operator must control the inlet and outlet air valves to make the air volume of the system in a balanced state, so as not to affect the air pressure at the back end of the rotary kiln. We are AGICO, a professional cement equipment manufacturer and cement plant contractor.

A famous beached concrete ship suffered the latest in a long line of casualties over the weekend as explosive surf, brutal storms and recordsetting waves lashed at its core. The stern of the ...

· Direct and coordinate the activities of employees engaged in the raw mill, coal mill and clinker production. ... VRM/Coal Mill Operator at Habesha Cement October, 2023. Ethiopia October 27, 2023 Apply Now 2 mins ago. Filed Sales Representative at Holland Dairy October, 2023.

EVALUASI SISTEM KINERJA ALAT DAN PEMROSES PADA CEMENT MILL DI PT. SEMEN BATURAJA (PERSERO) Tbk Authors: Yona Rizky Amelia Akhwari Pamungkas Safar Uddin PT. Semen Baturaja (Persero) Tbk....

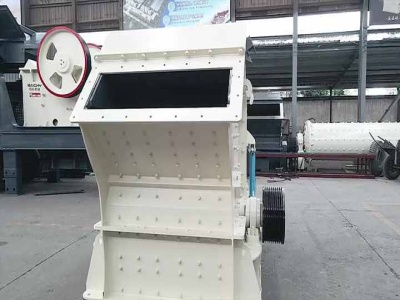

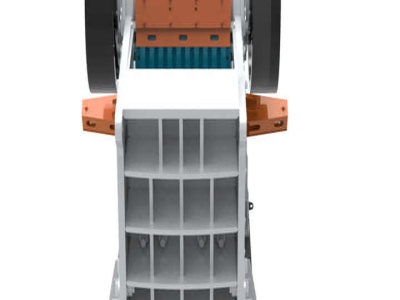

The cement roller press is a type of materialcrushing machine which is often used in cement plants. It usually works together with a ball mill to form a pregrinding or finalgrinding system for the grinding of raw materials, coal, and clinker.. Compared with the traditional tube mill and ball mill, the roller press has lower energy consumption and higher production efficiency, consumes less ...

A coal mill with a heat source other than the kiln or a coal mill using exhaust gases from the clinker cooler is not an inline coal mill. Inline kiln/raw mill means a system in a portland cement production process where a dry kiln system is integrated with the raw mill so that all or a portion of the kiln exhaust gases are used to perform the ...

PFISTER products and solutions are applied in many heavy industries such as cement manufacturing, mining and minerals, coalfired power plants or steel, iron and aluminum plants. Our equipment provides industryleading dosing and weighing accuracy and supreme application versatility. Our Pfister product brand offers products and solutions for ...

cement factory coal mill system test. goal mill in cement factory. Function Of Boal Mill In Cement Factory Grinding mill for cement factory you4baselement mill wikipedia cement mill or finish mill in north american usage is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that Coal Mill PriceCement Coal Mill Price The strong ...

A conventional cement grinding circuit is composed of a two compartment tube mill, a mill filter which collects the fine material inside the mill and a dynamic air separator where final product ...

Sebagaimana sistem utama pabrik semen lainnya, target operasi coal mill di pabrik semen adalah mencapai produksi maksimal berupa tonase produk dan kualitas berupa kadar air dan kehalusan serta operasi yang ... supervisor produksi area cement mill, dan operator produksi coal mill, yang mengarahkan kepada efektifitas

where S c is the cement market price per ton, ecost j is the electricity consumption cost of cement j, Δμ j is the average electricity price of cement j within T, d j is the electricity intensity of cement j, BP j is the power of kiln in cement j, ocost j includes additional costs of cement j, including limestone, coal and labor cost, etc.

A 10 MW cement mill, output 270 tonnes per hour. A cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

ANALISA KINERJA SISTEM DUST COLLECTOR TIPE BAG HOUSE FILTER 43BF21 UNIT COAL MILL BERDASARKAN FAKTOR CAN VELOCITY PABRIK II PT SEMEN BATURAJA TBK. ... The final results showed that the Can ...

The cement industry is one of the most intensive energy consumers in the industrial sectors. The energy consumption represents 40% to 60% of production cost. Additionally, the cement industry contributes around 5% to 8% of all manmade CO2 emissions. Physiochemical and thermochemical reactions involved in cement kilns are still not well understood because of their complexity. The ...

Over many decades, cement has been the primary component in construction projects and is considered one of the essential industries worldwide. At the same time, it overconsumes natural resources and can negatively impact the environment through a few byproducts, such as carbon dioxide (CO2) and cement kiln dust (CKD). The generated quantity of CKD is estimated to be 1520% of the produced ...