This scenario assumes that the mills adoption rate of this technology starts to linearly increase from 0% in 2020 and reach 100% by 2030. The scenarios IRPAG and GOPAG assume 13% energy savings and 25% reduction in ball consumption (Nkwanyana and Loveday, 2017), achieved by the addition of pebbles to ball mills in iron and gold mining, respectively.

SAG و BALL MILLS الصين

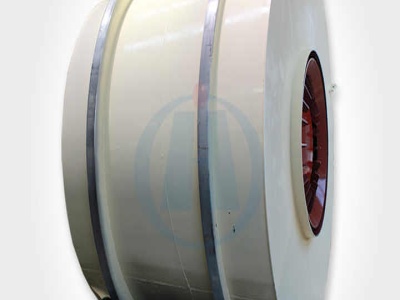

sag mill liner Manufacturers, Factory, Suppliers From China, We, with open arms, invite all interested potential buyers to visit our website or get in touch with us immediately for further information and facts. ... AS2074 L2B و L2C SAG و AG Mill Liner ...

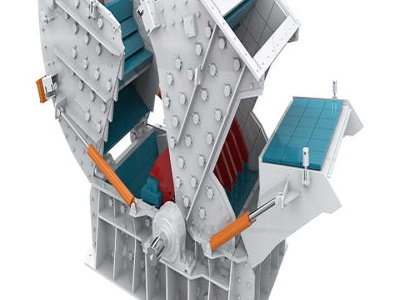

SAG mills and AG mills have different definitions and operate differently. SAG mills use a combination of steel balls and rock particles as grinding media, while AG mills use only the ore itself. Both types of mills are used for grinding ore in mineral processing operations, but SAG mills are larger in size and can grind larger quantities of ore.

One of the biggest mining machinery manufacturer in China. Professional low price. Mills SAG, Ball Rod Home Page Equipment List • home equipment list • special projects • about us • community • privacy policy • contact us • email us: Mills SAG, Ball Rod Sag ball mills | Sag ball mills Manufacturers Suppliers at .

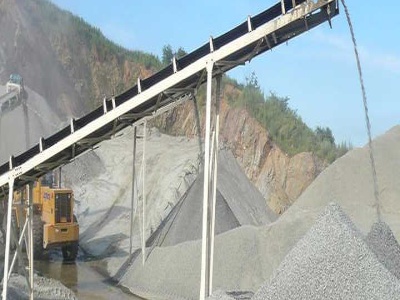

Crushed ore is fed to the ball mill through the inlet; a scoop (small screw conveyor) ensures the feed is constant. For both wet and dry ball mills, the ball mill is charged to approximately 33% with balls (range 3045%). Pulp (crushed ore and water) fills another 15% of the drum's volume so that the total volume of the drum is 50% charged.

basis was a SABC circuit of 8% ball charge. Maximum SAG mill power was determined by deducting the installed ball mill pinion power of kWh/t from the maximum overall circuit power of kWh/t to give kWh/t. Overall power for the comminution circuit (SAG plus ball mills) base on a

1 / 6 China Wet Type Mineral Grinding Machine Sag Ball Mill for Sale US / set 1 set (MOQ) Aftersales Service : 24hours Warranty : 2 Years Application : Mineral Operation Certification : ISO More Henan Hongji Mine Machinery Co., Ltd. Contact Now Inquiry Basket

وصف المنتج SAG Mill Liner من HG تستخدم مواد CrMo (معيار AS2074) ، توفر SAG Mill Liner تأثيرًا عاليًا ومقاومة للتآكل في جميع تطبيقات الطحن شبه الذاتية. مهمتنا هي اختيار المادة المناسبة للتطبيق الصحيح ، فنحن نعمل دائمًا معًا ...

Mill Type Overview. Three types of mill design are common. The Overflow Discharge mill is best suited for fine grinding to 75 106 microns.; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 250 microns.; The CenterPeriphery Discharge mill has feed reporting from both ends and the product discharges ...

mm were replaced with 80 mm balls to reduce the amount of coarser particles in circulation. Larger balls reduced the number of particles coarser than 1 mm by about 5%. In case the feed to ball mill was equal to 1200 Mg/h, it resulted in a reduction of 60 Mg/h of the weight of coarse particles in circulation. It also enabled the processing of a ...

based on semiautogenous (SAG) milling and involve as a rule primary wet autogenous mill (WAM) and a series of ball mills. WAM is customary chosen either based on examination of analogous equipment specifications, or from the evidence of very expensive commercial and semicommercial testing that requires large sampling, much time and high investment

Business Articles Ball Mill vs SAG Mill: What's the Difference? in Manufacturing Grinding is an essential part of the manufacturing process. When you are choosing a grinder, you have several options to choose from. Two of the most common types of mill grinders are ball mills and SAG mills. While they may seem similar, they are quite different.

A milling circuit consists of a primary SAG mill that is in open circuit. This is then followed by 2 secondary ball mills in parallel. ... The product from the SAG mill is fed to the ball mills, with the product from the ball mills being combined and classified in cyclones. The underflow from the cyclones is recycled, with the overflow forming ...

m length (190) single SAG mill equipped with a 20 MW electric motor. The SAG mill product flows to two m (120) by m (240) horizontal screens, whose combined oversize (pebbles) is diverted to two Metso MP 800 cone crushers. The crushed product returns to the SAG mill feed, closing the primary grinding circuit. The horizontal screen ...

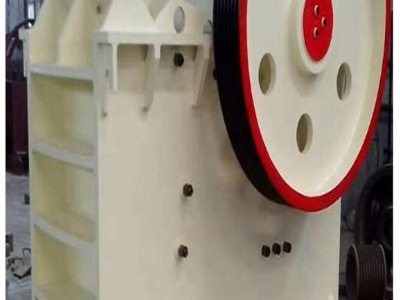

Ball mill is an important kind of grinding equipment used to decrease the size of ore particles. The power consumption of a ball mill is one of the most important parameters to consider in the design of a ball mill because it determines its economic efficiency. ... (SAG) mills. Generally, fill level, mill speed, shape and number of lifters, and ...

آسیاب گلولهای یا گویآس [۱] (به انگلیسی : Ball mill) گونهای از آسیابهای صنعتی است که جهت تولید پودر نرم یا یکنواخت کردن مخلوط به کار میرود. در آسیاب گلولهای از گلولههای فولادی یا سرامیکی ...

Grinding and processing. WEG offers the most reliable and efficient solutions for milling plants for ferrous and nonferrous products with their experience of mill drive systems. In the heart of a processing plant, the ball and SAG mills must be driven by solutions that adapt to the characteristics of the minerals in line with the whole process.

SAG mills are autogenous mills that also use grinding balls like a ball mill. A SAG mill is usually a primary or first stage grinder. SAG mills use a ball charge of 8 to 21%. The largest SAG mill is 42' () in diameter, powered by a 28 MW (38,000 HP) motor. A SAG mill with a 44' () diameter and a power of 35 MW (47,000 HP) has been ...

HPGR test results published by Grier (1992) on gold ores from the Mt. Todd project showed significant energy savings for a HPGR/Ball Mill circuit as compared to a SAG/Ball Mill plant. By adding a Polycom highpressure grinding roll, the throughput of existing plants can be increased by as much as 150% while simultaneously reducing the power ...

A SAG mill is a type of mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually to times the diameter of the shell. The SAG mill operates in a closed circuit with a screen. The product from the SAG mill is fed to a ball mill, which operates in a closed circuit with a cyclone.

Assuming your ore is AGamenable: 7 TPH to 15 TPH is a comfortably production average for a 13′ x ′ AG Mill. A 13′ x 6′ SAG Mill has a reasonable range of: 20 to 30 TPH for gold ore SAG Ball Mill duty. 25 to 40 t/h for copper porphyry SAG Ball Mill duty. In Single Stage SAG duty, the approximate capacity reduces to only 8 to 13 ...

Open Circuit Grinding. The object of this test was to determine the crushing efficiency of the ballmill when operating in open circuit. The conditions were as follows: Feed rate, variable from 3 to 18 T. per hr. Ball load, 28,000 lb. of 5, 4, 3, and 2½in. balls. Speed,

Single stage SAG Mills are very beneficial in reducing CAPEX for plants with a staged throughput approach. When future tonnage is to be increased, the SAG Mill can feed downstream ball milling to boost capacity. FullerTraylor SAG/AG Mills range in size from through in diameter with powers as high as 28,000 kW.

https:// A Laboratory Ball Mill, because the calibrated grinding energy m...

The working principle of the selfgrinding machine is basically the same as the ball mill, the biggest difference is that the sag grinding machine uses the crushed material inside the cylinder as the grinding medium, the material constantly impacts and grinding to gradually pulverize.

Working Principle of a SAG Mill. The rock and grinding media are placed in the mill and rotated, causing the grinding media to tumble and crush the rock into smaller pieces. The mill operates in a closed circuit with screens that size the ore and send it back to the mill for further grinding. The product from the mill is then sent to a cyclone ...

In this paper we present a study of the discharge of balls and fluid slurry out of the end of an industrial scale overflow ball mill and into a trommel using a 2way fully coupled DEM + SPH model. The DEM submodel is used to represent the ball charge while the SPH method is used for the fluid slurry containing the fine product.