3D modeling of micro ballend milling cutter. In this paper, a 1mm micro ballend milling cutter is used as the milling cutter with the detailed parameters shown in Table cutting edge is an equal lead spiral with a rounded cutting edge radius ({R}_{mathrm{e}}) of 1 μm, as shown in Fig. the modeling process, the cutter was modeled by combining the cutting edge curve ...

Micro Ball Milling Australia

Shop our selection of micro milling cutting tools, offered in multiple overall lengths, flute lengths, flute count styles, and square, ball, and corner radius profiles. ... 3 FluteBall30° HelixLong Flute. Long Flute Micro End Mills engineered with 3 flutes, a ball profile, and AlTiN coating for increased wear and heat resistance . . . ...

microne grinding machine | Crushing and Screening Plant .. As a professional micron micro grinding supplier .. Grinding mill for calcium carbonate powder grinding plant Ball mill is the widely used Calcium ..

Microend milling is considered to be one of the favourable types among these techniques due to its higher flexibility and applicability over a wide range of materials.

Machine tool developer EMCO is a worldwide leading manufacturer and producer of lathes and milling machines. This manufacturer follows the most modern and international standards and offers workshops and training in CNC machines, milling and turning. The EMCO Group thus enables complete solutions with advanced training and consulting in the form of workshops and instruction on training ...

[11] Berestovskyi D, Hung WNP and Lomeli P 2014 Surface finish of ballend milled microchannels Transaction ASME Journal of MicroNano Manufacturing 2 110. Google Scholar [12] Arif M, Rahman M and San WY 2012 An experimental investigation into micro ballend milling of silicon Journal of Manufacturing Processes 14 5261. Crossref; Google Scholar

Micro ball end milling with the optimally selected input parameters enables the simultaneous minimization of forces, vibrations and surface roughness. Thus, the obtained results can be implemented during precise 5axes micro ball end milling of a complex surfaces with the application of constant tool's axis inclination along the toolpath.

Microendmilling is a cutting technology that removes redundant material from machined workpieces by smalldiameter end mills, and is widely used to manufacture miniature complex parts. During microendmilling, the cutting vibration caused by weak tool rigidity and high spindle speed is known as a key factor for decreasing machined quality and accelerating tool failure. This study reports on ...

Descriptions For Micro Ball End Mill. Our carbide micro ball nose end mill strictly produces according to German Standard, the average of solid carbide we used is μm with ALoCa3 coating. It can treat workpiece up to HRC55. And, you can use it to realize profile milling, cavity machining, spherical slot processing.

Matsumara and Ono [37, 38] analysed an influence of tool inclination on surface generation during micro ball end milling of glass. Authors pointed out that due to absence of elastic deformation in glass, the edge roughness of cutting tool is transferred directly onto the surface without elastic recovery.

In another study, pluronic F68, a soft and meltable material that may be used both as an excipient and active ingredient in inhalable dry powder formulations [103], was subjected to a microball milling technique using stainless steel ball bearings as the grinding agent. Ball milling was carried out in the presence of liquid nitrogen vapor.

Since cemented carbide has been used as a microlens array mold, its processing method and microtool is one of the research priorities. In order to achieve highquality milling of cemented carbide microlens array, the design and fabrication of the diameter polycrystalline diamond (PCD) micro ballend mill were studied. Based on the space vector, the mathematical model of the plane ...

Planetary Ball Mills. Sample volumes up to 4 x 220 ml. Final fineness*: µm. Extremely high centrifugal forces result in high energy input. Dry and wet grinding by impact and friction. To the product range. Ultrafine grinding with up to 76 g.

Potassium dihydrogen phosphate (KDP or KH2PO4) crystal is widely used as terminal frequency converters in inertial confinement fusion (ICF). However, KDP crystal is a typical difficulttocut optical crystal with the characteristic of softbrittle. In this work, the relationship between cutting force and processed surface quality in micro ball endmilling of KDP crystal with various depth of ...

Micro Milling 89 Cathcart St, Goulburn NSW 2580, Australia. Micro Milling is located in Goulburn Mulwaree Council of New South Wales state. On the street of Cathcart Street and street number is 89. To communicate or ask something with the place, the Phone number is (02) 4822 can get more information from their website.

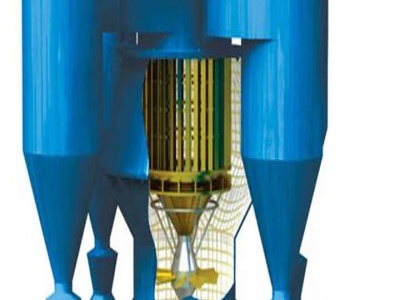

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles ...

Ball milling is a simple, fast, costeffective green technology with enormous potential. One of the most interesting applications of this technology in the eld of cellulose is the preparation and the chemical fi modi cation of cellulose nanocrystals and nano bers. Although a number of studies have been reported fi fi

89 Cathcart Street Goulburn, NSW, 2580 Australia Phone: 0447 341 721 Contact Company Information MicroMilling Pty Ltd Since 1991 Micro Milling's flour operations have been grinding, drying and sizing organic material.

The high quality of the micromachined surface is the basic for promoting micromilling technology, so the understanding of surface forming mechanism and the relationship between micromilling parameters and the surface roughness are important. In this paper, we establish a comprehensive floor surface model which predicts the surface roughness of the grooves under different cutting parameters ...

A typical type of fine grinder is the ball mill. A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grinds material to the necessary fineness by friction and impact with the tumbling balls. ... Micro Ball Mill. 1. MBM600. High Energy Ball Mill. 1. PBM6. Planetary Ball Mill,speed ...

Here, we presented a linear compensation of tool electrode and a proportional variable thickness method for milling microball sockets in C17200 beryllium copper alloy by microelectrical discharge machining. The machining parameters were systematically investigated and optimized to achieve highprecision microball sockets when the k value was ...

Type of ball mill: • There is no fundamental restriction to the type of ball mill used for organic synthesis (planetary ball mill, mixer ball mill, vibration ball mill, .). • The scale of reaction determines the size and the type of ball mill. • Vessels for laboratory vibration ball mills are normally restricted to a volume of 50 cm3.

When serving in extremely highpower laser conditions, KH 2 PO 4 (KDP) surfaces are susceptible to incur laser damage points (also known as defects). Using microball end milling cutters to repair and remove the preexisting damage points on the flawed KDP crystal surface is the most effective method to control the growth of laser damage points on KDP crystal surfaces and prolong their service ...

Guhring Australia is the leading supplier in highperformance precision cutting tools, gun drills, end mills, carbide inserts, carbide tools, countersinks, custom tools, milling cutters, threading tools and twist drills. Contact us for services such as PVD coating, reconditioning, regrinding, resharpening, tool management and tool manufacturing.

Through micromilling experiments on Al7075T6 materials, the change of milling force in the plough zone and shear zone during micromilling was studied, and the minimum cutting thickness (hmin ...

Micromilling tests with a micro ballend cutter were performed on an ult raprecision five axis machine tool, as shown in (a). The spindle used is the highspeed ae rostatic spindle (EM3080 J,

Microstructure Characterizations of GO/CZC Composite Powder. Figure 2 shows the SEM images of GO/CZC powders after different ball milling times. The raw CZC powders in Fig. 2(a) exhibit spherical shapes with smooth surfaces. Some deformed CZC powders with relative rough surface were observed when the ball milling times increased from 0 to 10 h, as compared with Fig. 2(a), (b), and (c).

The objective of the present work is the comparison of two common milling methods for the production of complex metallic alloy nanoparticles. γAl 12 Mg 17 nanoparticles were fabricated using both a planetary ball mill and a SPEX mill. The produced nanoparticles have been compared on the basis of the phase and microstructural characterisations by means of Xray diffraction (XRD) and field ...