Nonferrous ore mines employ more people than do iron ore mines, and there are also more mining facilities of this kind. ... which reduced the need for limestone deliveries to steel mills. ... in the dimension stone industry increased significantly in 2021 compared with 2020. 216,000 tonnes of finished products were delivered in 2021, in the ...

Ag Mill Mill Iron Ore Mine Products

The Zourerat iron ore mine has two m diameter × m wide HPGR units treating 1400 t/h each of aerofall mill pebbles. The feed is − 25 + mm and has a ball mill work index of 1214 kWh/t. The iron ore has low to moderate abrasion characteristics. Figure shows the Zourerat iron ore flowsheet.

Tozlu and Fresko (2015) estimated that the total installed motor capacity of AG/SAG mills in hard rock mining in 2015 was million kW (see Fig. 1).Given that mining industry activity has been relatively slow since then, additional sales of AG/SAG mill capacity from then until now (2021) would possibly be no more than million kW.

Mining and processing wastes are defined as solid and liquid byproducts of mining, mineral processing, and metallurgical extraction ... These include ore pebbles (for fully autogenous or AG Mills), a mixture of steel balls and pebbles (semiautogenous or ... Iron Ore, Woodhead Publishing (2015), pp. 251282. View PDF View article View in ...

The Hull Rust Mahoning Mine in Hibbing, Minnesota. World's largest open pit iron ore mine. First ore shipments in 1895 (still being mined today, 114 years later) Originally 30 separate mines. Total area: 1,591 acres. Total length: 3 1/2 miles. Greatest width: 1 1/2 miles. Greatest depth: 535 feet.

Processed taconite pellets as used in the steelmaking industry, with a US quarter ( in./ mm) shown for scale.. Iron mining in the United States produced 48 million metric tons of iron ore in 2019. Iron ore was the thirdhighestvalue metal mined in the United States, after gold and copper. Iron ore was mined from nine active mines and three reclamation operations in Michigan, Minnesota ...

Our customer, Yoo Gyeong, awarded its first contract for its KyungNam terminal to LOESCHE GmbH, the market leader in cement grinding. To grind the granulated blast furnace slag, the customer will use an LM +2 CS type LOESCHE mill with a capacity of 90t/h at 4,500Blaine as a reliable unit. The gearbox of this mill has a power output of 2,800kW.

Comminution is the reduction of solid materials from one average particle size to a smaller average particle size, by crushing, grinding, cutting, vibrating, or other processes. In geology, it occurs naturally during faulting in the upper part of the Earth's crust. In industry, it is an important unit operation in mineral processing, ceramics, electronics, and other fields, accomplished with ...

The effect of blending two hard and soft iron ores on the AG mill performance. • Decreasing the AG mill power consumption by decreasing the feed ore hardness. • Modifying the MINNOVEX model for the prediction of the AG mill power consumption. Download fullsize image Keywords Autogenous mill Direct addition large lumps of ore Ore hardness

ClevelandCliffs. ClevelandCliffs Inc., formerly Cliffs Natural Resources, is a Cleveland, Ohio based company that specializes in the mining, beneficiation, and pelletizing of iron ore, as well as steelmaking, including stamping and tooling. It is the largest flatrolled steel producer in North America.

Australian and Brazilian iron ore miners are safe for now. Steel mill owners in parts of China are in a bad mood, Beijingbased commodities consultant Simon Wu said. Steel inventories are slowly ...

Semiautogenoussingle stage. These circuits are not a good choice for many orebodies because it is not logical to expect one machine to be as efficient on 150 mm ore as it is on 100 micron ore. Semiautogenous plus ball mill has been the "work horse" of mills. SAG vs Ball Mill Advantages . AG SAG Mill Grinding Compared Which is Best

If the gangue mineral in an iron ore is predominantly quartz, reverse flotation is usually used in the cleaning stage to improve the concentrate grade. Figure presents a typical flow sheet for processing an oxidized iron ore containing about 30% Fe using a combination of SLon magnetite separators and reverse flotation. The ore is mainly composed of magnetite, hematite, martite, and quartz.

1. Structure. Although the overall structure of autogenous grinding mill and ball mill are similar, but there are differences in details. There are differences in the ratio of the length and width of the barrel between ball mill and AG mill. The large diameter and short length of the barrel of the AG mill reduce the axial segregation of ...

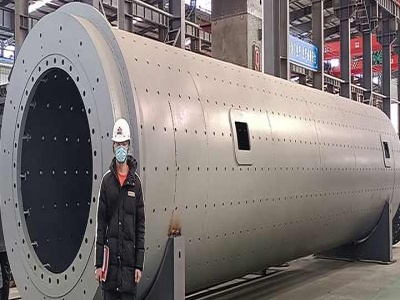

Sino Iron uses largest AG mills in the world, at in diameter and 11m long with 28MW gearless motors. The ball mills, the second stage grinding equipment, are in diameter and long, each with two 7800 kW motors. 52 magnetic separators are used in each of the processing lines.

Multotec's heavy mineral spiral test units are supplied by pumps driven by variable speed drives, operating between 380 V or 525 V and processing up to 20 tons per hour. The VV range of hydrocyclones offers the client the most costeffective solution for most fine cutpoint classification applications.

The sample of coarse iron ore was characterized in laboratory tests carried out in a small batch ball mill. Selection and breakage function parameters were determined from the laboratory tests.

The Mesabi Iron Range's history as a mining district begins well before ore was unearthed. More than two billion years ago, an era of mountain building known as the Algoman orogeny occurred.

Woodward Iron Company Four ironmaking enterprises, each controlling substantial deposits of iron ore, coal, limestone, and dolomite, came to dominate the industry. These companies were unique in their use of advanced blastfurnace plants that smelted iron ore into pig iron. Woodward Iron, Sloss Sheffield Steel and Iron Company, and Thomas Works operated blastfurnace plants that produced pig ...

Slag. Molten slag is carried outside and poured into a dump. Slag is a byproduct of smelting ( pyrometallurgical) ores and recycled metals. [1] Slag is mainly a mixture of metal oxides and silicon dioxide. Broadly, it can be classified as ferrous (byproducts of processing iron and steel), ferroalloy (byproduct of ferroalloy production) or ...

Iron Ore powder processing technological process. Phrase one: raw material crushing. Iron ore blocks will be crushed to 15mm50mm fineness by crusher. Phrase two: grinding. Crushed iron ore blocks will be sent to the storage hopper by elevator, and then sent to main mill for grinding through feeder. Phrase three: classifying.

3. Feeding the crusher (Reclaim) The surge pile allows a constant supply of material to be fed into the mill, which ensures consistent results and stability in the ore recovery process. 4. Grinding. The primary grinding mill grinds the material before it undergoes spiral gravity separation.

Abstract. This chapter considers comminution for gold ores, starting with breakage induced in the blasting process, continuing through primary crushing, primary milling, and secondary milling. Both technical and operational considerations are reviewed; while gold ore comminution is broadly similar to likesized circuits for other mineral ...

Iron (Fe) is a metallic element that constitutes % by weight of the Earth's crust and is the fourth most abundant element in the crust. Iron ores are rocks from which metallic iron can be economically extracted. The principal iron ores contain hematite (Fe 2 O 3) and magnetite (Fe 3 O 4 ). Hematite is an iron oxide mineral.

Iron Ore, Concentrates 120180 Iron Ore, Crushed 135150 Iron Oxide, Pigment 25 Iron Oxide, Mill Scale 75 Iron Pyrites (See Ferrous Sulfide)Iron Sulfate (See Ferrous Sulfate)Iron Sulfide (See Ferrous Sulfide)Iron Vitriol (See Ferrous Sulfate)Kaffir Corn 4045 ..., Agricultural, 1/8 Inch and Under 68 Limestone, Crushed 8590 Limestone, Dust ...

Hematite, the main iron ore found in Brazilian mines Stockpiles of iron ore pellets like this one are used in steel production An illustration of iron ore being unloaded at docks in Toledo, Ohio. Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, or deep purple to ...

To select the correct materials of construction, a combination of the applications' function, ore abrasivity, mill size, mill speed size of the balls and the type of corrosive environment need to be considered. Symptoms of poor liner design, which means your mill liner may require reevaluation, include a noisy mill and broken mill liners.

Ore blending is an essential part of daily work in the concentrator. Qualified ore dressing products can make the ore dressing more smoothly. The existing ore blending modeling usually only considers the quality of ore blending products and ignores the effect of ore blending on ore dressing. This research proposes an ore blending modeling method based on the quality of the beneficiation ...

An Aerofall mill is a type of autogenous grinding (AG) mill. It is a machine that uses a tumbling mill drum filled with ore and steel balls or rods to grind and reduce the size of the ore particles. The grinding process occurs due to the impact and abrasion of the ore particles against each other and the steel balls or rods within the drum.