A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles ...

Clinker Feed Trunnion Ball Ball Mill

Make it easy to allow the material feed and ventilation air separately in the ball mill feed and ensure an. increased air flow through the mills for better ventilation with our stationary inlet for ball mills. PRODUCT DATASHEET. The prime purpose of our stationary inlet is to direct the . feed materials (clinker gypsum (or raw meal) and ...

Ball mill bearings are important components of ball mills, vertical mills, rotary kilns, rolling mills, and other equipment, and their quality directly affects production efficiency and safe operation of equipment and is also one of the clinker equipment. Ball mill bearings usually use highquality steel materials, such as GCr15, which can ...

AGICO cement ball mills have a wide range of models, with a maximum output of 130 tons per hour, which can meet the production needs of large, medium, and small cement manufacturers. Based on the grinding system used by customers, we can customize and optimize the ball mill. Whether it is an opencircuit grinding system, a closedcircuit ...

From mill shells to trunnion liners and everything in between, a trunnionsupported mill works better with more durable, higher performing parts. Our replacements provide premium service to customers, promoting innovative design and increased durability. Enjoy lower costs and less downtime with EXCEL premium trunnionsupported mill parts.

mill/sbm kolkata clinker feed trunnion bearing ball rwrr KiB

Working Principle of a SAG Mill. The rock and grinding media are placed in the mill and rotated, causing the grinding media to tumble and crush the rock into smaller pieces. The mill operates in a closed circuit with screens that size the ore and send it back to the mill for further grinding. The product from the mill is then sent to a cyclone ...

The ball milling process is generally divided into two types, the dry ball milling process, and the wet ball milling process. This article takes dry ball milling as an example to introduce the ball milling process. First, select the appropriate size and weight of the grinding medium according to the particle size of the grinding material.

Steel Ball Mills Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800's. The basic construction of a ball mill is a cylindrical container with journals at its axis. The cylinder is filled with grinding media (ceramic or metallic balls or rods ...

In the manufacture of standard cement by grinding cement clinker, ... Preparing ball mill feed for two or more stages of grinding. 3. Producing a material with a minimum of fines and a minimum of tramp oversize material. ... 301 Feed Trunnion Liner. 302 Plain Discharge Trunnion Liner. 303 Discharge Trunnion Liner and Spout.

The use of ball mills for reducing crusher product to 85 per cent,: below 200mesh in two stages, as practised at the United Eastern, Tom Reed, and Montana mines, in Arizona, is a distinct advance in fine crushing. The simplicity, small floor space and large capacity of these installations are especially notable.

An inefficient ball mill is a major expense and could even cost you product quality. The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance. With more than 4000 references worldwide, the FLSmidth ball mill is proven to do just that.

At most manufacturing plants the ball mill is used to grind the clinker and, since the production rate is directly related to the amount of electrical energy supplied, the power of the electric motor used to turn the mill is a firstorder measure of the output achieved. Mills vary in their power input from as little as 200 kW up to 10000 kW.

The trunnion liner on the feed end of the mill may have a WORM to assist the ore into the mill. This worm acts like an auger or a screw. As the mill turns the spiral will pull the feed into the mill. ... BALL MILL FEED BOX. Ordinarily the feed box for a scoop feeder is designed and supplied by the user. The feed box should be so constructed ...

They were introduced in 1993 at Buzzi Unicem's Trino plant in Italy with the purpose of reducing energy costs. Details of the operating principle of Horomill ® as compared to HPGR and vertical roller mills are given by Cordonnier (1994) and Buzzi (1997).The energy saving of this mill is claimed to be similar to that of HPGR and 3050% lower than a ball mill (Cordonnier, 1994).

USED BALL MILLS for Sale CSC Special Offers. Trunnion bearing material inlet side: Circuit oil lubrication with two oil to a two compartment cement mill x cement mill inlet trunnion maintenance workcement mill inlet trunnion bearing trunnion bearing lubri ion methods cement ...

where d is the maximum size of feed (mm); σ is compression strength (MPa); E is modulus of elasticity (MPa); ρb is density of material of balls (kg/m 3); D is inner diameter of the mill body (m).. Generally, a maximum allowed ball size is situated in the range from D /18 to D/24.. The degree of filling the mill with balls also influences productivity of the mill and milling efficiency.

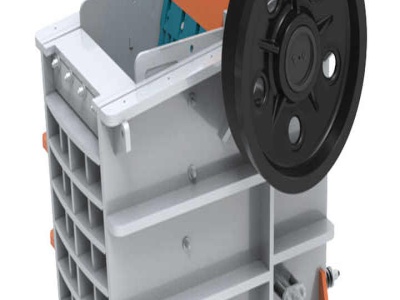

When selecting a ball mill trunnion for your mill, several crucial factors should be considered to ensure optimal performance and longevity. 1. The operating conditions and environment of the ball mill play a significant role in mill trunnion selection. Factors such as temperature, humidity, and the presence of corrosive substances must be ...

FLS Ball Mill Liners FLSmidth. Learn how to improve the performance and reliability of your ball mills with our durable and innovative liners. Our liners are designed to suit different grinding applications and reduce downtime. Download our brochure and discover the benefits of FLS Ball Mill Liners.

Single stage SAG Mills are very beneficial in reducing CAPEX for plants with a staged throughput approach. When future tonnage is to be increased, the SAG Mill can feed downstream ball milling to boost capacity. FullerTraylor SAG/AG Mills range in size from through in diameter with powers as high as 28,000 kW.

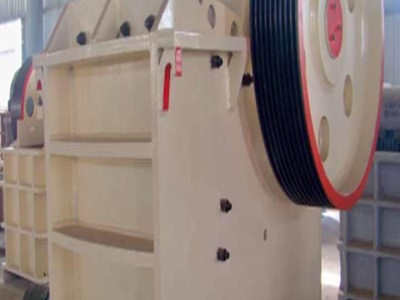

The ball mill trunnion is located at both ends of the ball mill cylinder and plays the role of supporting and connecting the mill cylinder. Two ball mill trunnions are installed at both ends of a ball mill, one is the feed trunnion, which is the passage for the material to be transported into the cylinder, and the other is the discharge trunnion, through which the ground material is sent out.

minus 6mesh feed is added to bring the total weight up to that of 700, and the charge is returned to the mill for a secontl grinding period. All standard ballmill tests are conductetl at 250 per cent circulating load, and the number of revolutions in the mill necessary to obtain this circulating load at any grind

For 60 mm (″) and smaller top size balls for cast metal liners use double wave liners with the number of lifters to the circle approximately D in meters (for D in feet, divide D by ). Wave height above the liners from to 2 times the liner thickness. Rubber liners of the integral molded design follow the cast metal design.

Modern ball mills may use between 32 and 37 fossil fuels and electricity, account for 30 to 40% of kWh/ton of electrical energy (Worrell et al., 2013). the industry's cash costs (Cantini et al., 2021; The power consumption of a ball mill rated MW International Finance Corporation, 2017; Worrell et stands at kWh/t of cement produced ...