This can reduce the energy consumption and the use cost of the ball mill. To make the milling more efficient, we must first be acquainted with the factors. They are mainly the ball mill structure, the rotation speed, the ball mill media, the lining plate, the material fed and the feeding speed, etc. In the following text, you will get some ...

Bauxite Ball Mill Optimization

The principal raw material for alumina production is bauxite Al 2 O ... together with any necessary additives, is ground in wet ballmills to a specified size range. Water is removed by spraying the aqueous suspension into a flow of hot gas (spraydrying) and separating the alumina in a cyclone unit. ... Optimization of calcination in terms of ...

Ball Mill Breakage Efficiency. Consider a ball mill circuit processing material of a given feed size and at a given throughput rate to a target product size, the latter which once again distinguishes the "fines" from the "coarse" material. The production rate of fines or new product size material can be calculated from the circuit feed ...

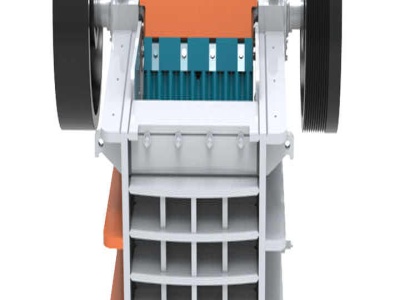

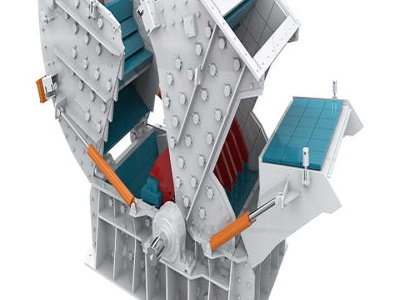

The process stages are: 1. Milling. The bauxite is washed and crushed, reducing the particle size and increasing the available surface area for the digestion stage. Lime and "spent liquor" (caustic soda returned from the precipitation stage) are added at the mills to make a pumpable slurry. 2.

COMPARISON OF VERTICAL ROLLER Survey 1 Ball mill circuit MILL AND CONVENTIONAL BALL MILL CIRCUIT By pass (%) Performances of vertical roller mill and closed ball mill d50c (µm) circuit in cement grinding application (CEM I R) Imperfection were compared in terms of energy consumption and Dust load (kg/m3) ...

4. B4 Milling ( Ball Mills ) Cement Plant Operations Handbook ICR 4th Edn. ( 2005 ). 5. A. Sahoo and G K Roy : "Correlation for the grindability of the ball mill as a measure of its performance" Asia Pacific Journal of Chemical Engineering 3(2) p. 230235 ( 2008 ). 6.

According to the calculations, the reduction ratios of rod and ball mills were and, which show high discrepancies from design values (23 and for rod and ball mills).

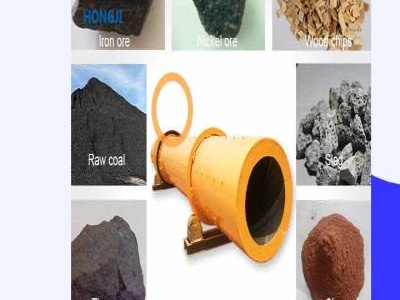

Wet grinding of the bauxite ore in rod mills, ball mills, or semiautogenous grinding mills to produce fine slurry. Digestion of the slurry by caustic soda (NaOH) at strengths exceeding 170 g/L in vessels under pressure at temperatures ranging from 145 to 265°C depending on the type of bauxite being processed.

In this study a novel synthetic method for the largescale production of spherical, high surface area and ultrafine alumina (Al 2 O 3) powder has been Bayer liquor was extracted by alkali fusion of raw bauxite with sodium hydoxide. Alumina nanopowders were synthesised through a ball millaided precipitation method using the synthetic Bayer liquor and mineral acid precipitants.

The feed rate to each 7 ft. diameter by 12 ft. long rod mill is approximately 95 tons per hour of bauxite ore. The minus 3/16″ product from each rod mill discharges to a ft. diameter by ft. deep Agitator equipped with a 42″ turbine type propeller consuming approximately 11

The process of Chromite ball mill beneficiation has many bottlenecks and needs refining with optimization of techniques. Clinker Grinding. 1 min read. Clinker Grinding. 1 min read. ... Ball Mill for Bauxite Processing Plant at Chanderpur Group Bauxite is an ore containing aluminum which has a wide application in cement, chemical, cosmetics, and ...

In order to maintain throughput, a VTM1250 was installed in semiparallel with the existing ball mill circuit. The VTM1250 accepted undersize from a new screen installed on a portion of the ball ...

Abstract An improved differential evolutionary cement mill operation index decision algorithm based on constraint control and selection strategy is proposed to address the problem that the operation index is usually decided by manual experience in the cement mill operation process, which causes unqualified cement specific surface area and excessive cement mill power consumption. The algorithm ...

Background Summary :

An Engineering Professional with PostGraduate Diploma (Operations Project Management IIM,Raipur) with over 24 Yrs. of Experience in Planning and Construction of Large Projects ( Industrial and Infrastructure) and Maintenance Management of Big Sized Plants Teams in Metals and Mining Organizations like Aluminium, Copper, and Diverse Experience in Operation ...

Normal Shutdown Sequence of Ball Mill and Grinding Circuit. Shut off cyanide metering pump. Put weight controller into MANUAL mode and turn controller output to 0%. Run the ball mill for 1530 minutes. Put density controller into MANUAL mode, set output to 0%. Put flow controller into MANUAL mode and set output to 0%.

autogenous, ball, and rod mills. By optimizing the grinding circuit arrangement, the amount of equipment can be kept to a minimum while ensuring the optimal particle size in the solid phase. Energyefficient digestion plant solutions We offer a broad range of digestion solutions, including singlestream hightemperature tube digestion. This

Abstract This paper examines the bauxite particle size requirements for the Bayer Process. A closed circuit SemiAutogenous Grinding (SAG) mill with a hydrocyclone is considered to be the most suitable for a high bauxite throughput operation.

With the same total media weight and a feed size less than mm, the breakage rate of the ceramic ball grinding approaches the steel ball grinding and is % higher than that of the steel ...

Contribute to brblmd/sbm development by creating an account on GitHub.

Assisted in sample preparation, data analysis and modelling for a bauxite ball mill optimization survey. Final results were reported and presented to the site senior management team. Industry Project Student Rio Tinto Mar 2012 Jun 2012 4 months. Melbourne, Australia ...

Ball Mill Linings; SAG Mill Liners; AG Mill Liners; Solid/Liquid Separation. Filter Press; ... Mechanical Design of the Worlds Largest Hammer Sampler For Bauxite Export Contractual Requirements. ... Milling Circuit Optimization Study for Kroondal 1 Platinum Concentrator.

The comparative analysis of three control strategies, single centralized MPC, decentralized MPC for SAG mills and ball mills, and multilevel control with a higher optimization layer and a lower decentralized MPC regulatory layer applied to a mineral milling plant, was presented by Karelovic et al. . The simulation results showed that the ...

The progress of the ball mill medium system and optimization[J]. Mining machinery, 2007.(in Chinese) [10]Choi, Applications of grinding kinetics analysis to fine grinding characteristics of some inorganic materials using a composite grinding media by planetary ball mill[J].Power Technology,2001,115(3):1990.

An improved sizemass balance model based on batchgrinding experiment was proposed to predict the particle size distribution of industrial ball mill, which had the characteristics of high ...

BALL MILLS ARE NORMALLY ABOVE WHILST VSMs ARE LESS THAN ... Other raw mill optimization considerations ... Sandstone ,Bauxite , Gypsum ; Bond Ball Work Index for Some cement ...